DEVELOPMENT OF ORGANIC SOUP FROM DRIED VEGETABLES

GROWN IN RWANDADECLARATION

I, UWAYO Désiré, an under

graduated student in the Faculty of Science, Department of Food Science and

Technology, with registration N° GS20050750, declare that the content of

this report entitled « DEVELOPMENT OF ORGANIC SOUP FROM DRIED

VEGETABLES GROWN IN RWANDA » is my own and original work. It is

submitted in partial fulfilment of the requirements for the award of a

Bachelor's Degree of Science in Food Science and Technology.

To the best of its value, it has never been submitted in any

University or in any other higher learning institution for any award.

UWAYO Désiré

..................................................

Date:

........................................

KIGALI INSTITUTE OF SCIENCE AND TECHNOLOGY

INSTITUT DES SCIENCES ET DE TECHNOLOGIE DE

KIGALI

Avenue de l'Armée, B.P. 3900 Kigali, Rwanda

FACULTY OF SCIENCE

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

CERTIFICATE

This to certify that the Project Work entitled «

DEVELOPMENT OF FLAVOURED ORGANIC SOUP ( for export) FROM DRIED

VEGETABLES GROWN IN RWANDA » is a record of the original

benefice work done by UWAYO Désiré under my supervision, in

partial fulfilment of the requirements for the award of Bachelor's Degree of

Science in Food Science and Technology in Kigali Institute of Science and

Technology (KIST), during the Academic Year 2008.

Supervisor: Mr. Dominique S. NKUNDA

Head of Department of Food

Date..............................................

Science and Technology

....................................................

...............................................

DEDICATIONS

To JEHOVAH, the Almighty God for his protection and special

favors he provided me.

To my beloved wife KWIZERA Naomi, for her care and support

during all my work.

To my mother BARAYAVUGA M. Rose for the attention and

sacrifices she made for me to become what I am today.

To my brothers, sisters and other family members, friends and

relatives.

I dedicate this outcome of my four years.

May JEHOVAH protect and bless you.

ACKNOWLEDGEMENTS

My first and special thanks go to JEHOVAH, my Almighty God for

giving me life, and being my guide from my birth till now, without him nothing

could have been achieved.

I also thank the Rwandan government which has contributed a

lot to my studies by giving me scholarship and KIST who have contributed to my

studies by providing all the necessary course materials.

Thanks to the Head of the Department of Food Science and

Technology and its staff, they were always in touch with me for advises about

techniques to use and how to do a usability studies.

Thanks go also to my unforgettable supervisor, Dominique S.

NKUNDA, for his continuous support and collaboration during this Research

Project.

Special thanks go to my wife who took care of me and assisted

me in different ways.

Special thanks go also to my Mother for all the sacrifices she

made for me to become what I am today.

I say thanks to my brothers Parfait BIZIMANA and

Dieudonné NIYIBIZI, and to my sisters Olive MUKASE and Solange UWAMAHORO

for sharing their experience of life with me, for listening to my complaints,

and for believing in me.

Further thanks are addressed to all members of my class for

their friendship and encouragement during the course of this study, for

interesting discussions made together and being fun to be with me. Thanks go to

all persons who contributed morally, materially and in any other form of help.

May God reward them for all those done for me!

Jehovah's blessings are my wishes to you all.

UWAYO Désiré

ABSTRACT

A soup is a

food that

is made by combining ingredients such as

meat or

vegetables

in

stock

or hot/boiling

water,

until the flavor is extracted, forming a

broth, but

here, only vegetables were used to develop an organic soup. Vegetables are

defined as either whole plants or only some parts of plants served with the

main course of a meal. The edible parts can be stems, roots, leaves, flowers,

fruits and / or grains. They normally contain between 90 - 96 % of moisture

when they are fresh. Drying was found to be one of the means of processing and

preserving them.

Value was added to the dried vegetables, by mixing

different ingredients in well defined proportions, and developing a well

appreciated naturally flavoured vegetable soup.

Different vegetables used as ingredients ( carrots,

celery, garlic, leek, onion, pepper, potatoes, and spinach ), were bought in

Kimisagara market, then dried into a hybrid dryer, blended, weighed and mixed

to develop the soup which was packaged in plastic bags and labeled. Laboratory

analysis and sensory evaluation were carried out so as to know the chemical

composition of the soup and its consumer acceptability. The soup was found to

contain an average value of 4.98% moisture content, 95.02% total solid matter,

as well as 13.06% crude protein, 3.17% lipids, 8.44% ash & minerals, 1.66%

vitamin C, and 68.69% total soluble sugars.

The mean score of  obtained on overall acceptability of the soup showed that it was accepted

and judged to be satisfactory.

obtained on overall acceptability of the soup showed that it was accepted

and judged to be satisfactory.

Keywords: Soup, Vegetable.

LIST OF ABBREVIATIONS

ANOVA : Analysis of the variance

aw : Water activity

ISAE : Institut Supérieur

d`Agriculture et d`Elevage

ISAR : Institut des Science Agronomiques

du Rwanda

MC : Moisture content

LIST OF FIGURES AND TABLES

1. FIGURES

Pages

Figure 2.2.1 : Picture of

spinach................................................................12

Figure 2.2.2 : Picture of potatoes

..............................................................13

Figure 2.2.3 : Picture of

leek....................................................................14

Figure 2.2.4 : Picture of

pepper.................................................................15

Figure 2.2.5 : Picture of

tomatoes.............................................................16

Figure 2.2.6 : Picture of

celery..................................................................17

Figure 2.2.7 : Picture of

carrot...................................................................18

Figure 2.2.8 : Picture of

onion...................................................................19

Figure 2.2.9 : Picture of

garlic...................................................................20

Figure 4.1: dried vegetables (after the process

drying)......................................28

Figure 4.2.2 : flow chart of soup

development................................................30

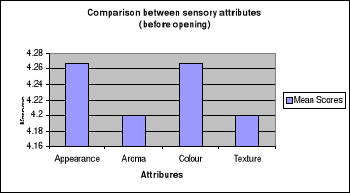

Figure 4.3.1 : graph of comparison between sensory attributes

( before opening ).......31

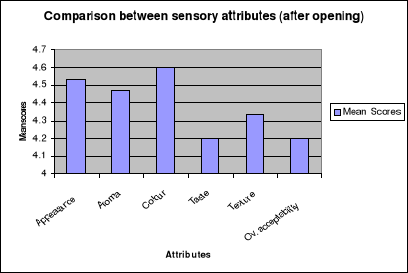

Figure 4.3.2 : graph of comparison between sensory attributes

( after opening )........33

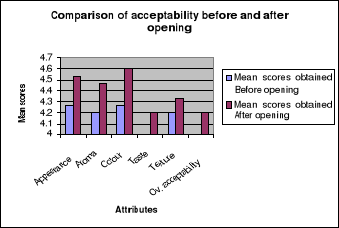

Figure 4.3.3. : graph of comparison of acceptability before

and after opening..........34

2. TABLES

Table 2.2.1: Nutritional value of

spinach.......................................................12

Table 2.2.2: Nutritional value of potato

.......................................................13

Table 2.2.5: Nutritional value of

Tomato.......................................................16

Table 2.2.6: Nutritional value of

celery.........................................................17

Table 2.2.7: Nutritional value of

carrot..........................................................18

Table 2.2.8: Nutritional value of

onion...........................................................19

Table 2.2.9: Nutritional value of

garlic...........................................................20

Table 3.3.2: composition of six proposed

soups................................................23

Table 4.1: results from the experiment of

drying..............................................28

Table 4.2.1: results of the first sensory

analysis................................................29

Table 4.2.2.a : composition of the formulated

soup...........................................29

Table 4.2.2.b : results of the second sensory

analysis.........................................30

Table 4.3.1.a : results of consumer acceptability check

(before opening)..................31

Table 4.3.1.b : summary of results of ANOVA ( before opening

)..........................32

Table 4.3.2.a : results of consumer acceptability check (after

opening)....................32

Table 4.3.2.b : summary of results of ANOVA ( after opening

)...........................33

Table 4.3.3. : comparison of acceptability before and after

opening........................34

Table 4.3.4 : results of consumer acceptability check for

packaging and labeling........35

TABLE OF CONTENT

Declaration............................................................................................i

Certificate.............................................................................................ii

Dedication.............................................................................................iii

Acknowledgments....................................................................................iv

Abstract................................................................................................v

List of

abbreviations.................................................................................vi

List of figures and

tables...........................................................................vii

Table of

content.....................................................................................viii

Chapter One :

INTRODUCTION..............................................................1

1.1. Problem

statement..............................................................................1

1.2. Significance of the

study......................................................................2

1.3. Objectives of the

study.......................................................................2

1.3.1. Main ( overall)

objective.....................................................................2

1.3. 2. Specific

objectives...........................................................................2

1.4.

Hypothesis........................................................................................3

Chapter Two: LITERATURE

REVIEW.....................................................4

2.1.

Definitions.......................................................................................4

2.1.1.

Soup............................................................................................4

2.1.2. Drying

..........................................................................................5

2.1.3.

Vegetables.....................................................................................6

2.1.3.i. Classification of

vegetables................................................................7

2.1.3.ii. Nutritional composition of

vegetables.................................................8

2.1.3.ii.a. Primary metabolites

......................................................................8

2.1.3.ii.b. Secondary

metabolites.................................................................10

2.1.3.iii. Effect of drying on

vegetables..........................................................10

2. 2. Some vegetables (

ingredients ) used ......................................................11

2.2.1. Spinach

.......................................................................................11

2.2.2.Potatoes.........................................................................................12

2.2.3.

Leek..........................................................................................13

2.2.4. Pepper

........................................................................................14

2.2.5. Tomatoes

.....................................................................................15

2.2.6.Celery...........................................................................................16

2.2.7.Carrot...........................................................................................17

2.2.8.Onion...........................................................................................19

2.2.9. Garlic

.........................................................................................20

Chapter Three : MATERIALS AND

METHODS........................................22

3.1. Research

design................................................................................22

3.2. Source of raw materials

....................................................................22

3.3. Experimental

procedures.......................................................................22

3.3.1. Preparation and drying of the

vegetables................................................22

3.3.2. Food formulation and

development......................................................23

3.3.2.i. Food formulation

proposal...............................................................23

3.3.2.ii. First sensory

analysis.....................................................................23

3.3.2.iii. Reformulation and second sensory

analysis..........................................24

3.3.3. Consumer acceptability

check...........................................................24

3.3.3.i. Statistical methods

used.................................................................24

3.3.4. Laboratory

analysis.........................................................................25

3.3.4.i. Moisture content

determination.......................................................25

3.3.4.ii. Ash and mineral content

determination.............................................25

3.3.4.iii. Carbohydrates content

determination................................................26

3.3.4.iv. Fat content

determination.............................................................26

3.3.4.v. Protein content

determination.........................................................26

3.3.4.vi. Vitamin C content

determination...................................................27

3.4. Pricing

mechanism........................................................................27

Chapter Four : RESULTS AND

DISCUSSION..........................................28

4.1.Drying of the

vegetables...................................................................28

4.2. Food formulation and

development.....................................................29

4.2.1. First sensory

analysis....................................................................29

4.2.2. Reformulation of the food and second sensory

analysis..............................29

4.3. Consumer acceptability

check............................................................31

4.3.1. Before

opening.............................................................................31

4.3.2. After

opening...............................................................................32

4.3.3. Comparison of acceptability before and after

opening..............................34

4.3.4. Assessment of the packaging and the

labeling..........................................35

4.4. Laboratory

analysis.........................................................................35

4.5. Price of the

product.........................................................................36

Chapter Five : CONCLUSIONS AND

RECOMMENDATIONS

5.1.

Conclusions................................................................................37

5.2. Recommendations

..........................................................................37

REFERENCES......................................................................................38

APPENDICES....................................................................................39

1. Questionnaire for suitable food formulation

..............................................40

2. Questionnaire for suitable cooking time and method

...................................42

3. Questionnaire for consumer acceptability

check..........................................43

4. Determination of total reducing sugar by Lane-Eynon

method.........................45

5. Determination of the fat content by the Soxhlet

method..................................47

6. Determination of protein content by the Kjeldahl

method.................................48

7. Determination of vitamin c content by indophenol

solution...........................50

8. Tables of results for consumer acceptability check ( before

opening)...................51

9. Tables of results for consumer acceptability check ( after

opening).....................52

10. Pricing mechanism for the developed

soup...............................................53

11. Label

used.......................................................................................54

Chapter One: INTRODUCTION

Fruits and vegetables are one among the most recommended and

essential foods because of their nutritional quality and effects on human body.

Some of the vegetables are considered to be important means of preventing

cancer through diet, and researches have shown mounting evidence that people

who avoid fruit and vegetables completely, or consume very little, are indeed

at increased risk of cancers diseases (TERRY et al

2001).

Some of the vegetables such as salad can be eaten uncooked,

while others require to be cooked or process before consumption. However, all

the production got can not be consumed efficiently, and this can lead to the

loss of a great part of the production of vegetables. It was observed that,

there are many varieties of vegetables and that until now, locally, there was

no way of processing them to increase their shelf life and to add to them

value. For this reason and others, it was necessary to carry out a research on

the way of processing vegetables in Rwanda.

1.1. PROBLEM STATEMENT

Rwanda, as one of the tropical region countries experiences

good climatic conditions and has a high production of different crops, among

which fruits and vegetables occupy a non negligible place.

However, an important part of this production of fruits and

vegetables is lost annually, because of poor post harvest handling. In fact,

vegetables as well as fruits have high moisture content and high water activity

(aw). These lead them to be highly perishable since

moisture content and water activity (aw) are ones

of the important factors to the growth of different microorganisms.

In addition, it is well known that during the harvest period,

the price of many food commodities including vegetables, is too low so that

farmers are losing and just after certain months, when comes the post

harvest period, there is lack or shortage of foods, then the price becomes too

high.

All these problems of production losses and fluctuation of the

vegetable prices on the market, can be overcome if the production of vegetables

were processed during the harvest period to increase their storage stability,

so that they can be stored longer and be used or sold during the post harvest

period. Keeping in mind that, water is the most important factor of the high

perishability of vegetables, their simplest method of processing, is drying

them in order to decrease their moisture content up to a level = 5% and water

activity = 0.20, where microorganisms are not favored to grow.

When are dried, vegetables can be used in many other ways, it

was necessary to study on how to develop a flavored organic soup ( for export

) from vegetables grown in Rwanda.

So these are the reason why the following research topic was

chosen: DEVELOPMENT OF ORGANIC SOUP FROM DRIED VEGETABLES GROWN

IN RWANDA.

1.2. SIGNIFICANCE OF THE STUDY

If well used, this research will be very important and

significant, since there will no longer be losses of vegetables because of lack

of (or poor) handling. In fact, this research shows how the excess production

of vegetables that can not be consumed directly during the harvest period, can

be processed in order to increase its stability and its shelf life, so that it

can be stored longer and be used further after.

Once again, the flavored organic soup produced, can be

exported to other countries, enabling the country to diversify the products it

exports and earn mach more foreign currency, what help in rising its economy.

1.3. OBJECTIVES OF THE STUDY

1.3.1. MAIN ( OVERALL) OBJECTIVE

The main objective of this study was to develop a flavored

organic soup (quality export), from dried vegetables grown in Rwanda.

1.3. 2. SPECIFIC OBJECTIVES

The specific objectives of this work were:

a. To formulate a flavoured soup (quality export), from dried

vegetables, grown in Rwanda.

b. To carry out a sensory evaluation of the formulated

food.

c. To determine the nutritional composition ( moisture

content, carbohydrates, proteins, fats, minerals and Vitamin C content) of the

formulated food.

d. To package and to label the formulated food.

1.4. HYPOTHESIS

The hypotheses of this research are as follows:

a. Dried vegetables can yield a good flavoured soup.

b. Food processing under guidance of consumer needs, allows

to achieve his satisfaction.

c. As moisture content in dried foods is too low, the storage

stability and the quality of the food will increase. However, vitamin C

content may be decreased by the fact of drying.

d. Dried soup has to be packed in containers that do not

allow (moisture) rehydration.

Chapter Two: LITERATURE REVIEW

2.1. DEFINITIONS

2.1.1. SOUP

A soup is a

food that is made by combining

ingredients such as

meat or

vegetables in

stock or

hot/boiling

water, until the flavor is

extracted, forming a

broth. It is sometimes

confused with

stew. The word soup

originates from "

sop", a dish originally

consisting of a soup or thick

stew which was soaked up with

pieces of

bread. The modern meaning of

sop has been limited to just the bread intended to be dipped.

Commercial soup became popular with the invention of

canning in the

19th century, and today

a great variety of canned and dried soups are on the market. Dr. John T.

Dorrance, a chemist with the

Campbell Soup

Company invented condensed soup in 1897. Today, Campbell's Tomato,

Cream

of Mushroom and Chicken Noodle soups are three of the most popular soups in

America. Americans consume approximately 2.5 billion bowls of these three soups

alone each

year (

www.wikipedia.org/wiki/soups

, 29/5/2008 ).

During the preparation of soups, there are so many important

factors that have to be taken into consideration. Some of them are listed below

:

The first one is «nitrate

content». Since nitrates can be carcinogenic, generally,

their use in food industry must as limited as possible. However their

limitation becomes furthermore important in soup making. This is so because

it has been demonstrated that , no nitrate was lost on cooking in accordance

with the manufacturers' directions; even when simmered for up to 25 minutes

(GARCIA-MATA et al 1995).

The second factor to be taken into account is the

«microbiological quality» of the soup. In

fact, studies have been carried out on the presence Clostridium

perfringens, one of the pathogenic and heat resistant microorganism, in

dehydrated soups and the organism was found in 18.2% of the samples. The soup

mixes had the lower incidence compared to Spaghetti sauce mixes that had the

highest incidence. One strain possessed heat-resistant spores that were able to

withstand boiling at 97.4°C for one hour prior to isolation. The presence

of preservatives in the food products did not influence the presence of C.

perfringens in these food preparations. So it is very important to pay a

strong attention on the microbiological quality of the soups and make sure

that it will be safe for human consumption since the general presence of this

microorganism in dehydrated soups and sauces may have epidemiological

significance in Clostridium perfringens food poisoning, especially

since these products are exposed to short besting periods (MITSURU, 1968).

The third factor, and last one on this list, is the

«use of organic vegetables» if the soup

must be commercialized. This will increase the consumers acceptability of the

soup and help in marketing. Studies have demonstrated that if consumers were

informed that soup is prepared with organic ingredients, they would improve

their acceptability scores, whatever the soup type. They revealed that

consumers appreciate soups made with organic crops and without seasoning

(MONACO et al 2007).

2.1.2. DRYING

Drying is probably the oldest food preservation process

practiced. Some foods, especially grains, are sufficiently dry as harvested or

with a little drying remain unspoiled for long periods under proper storage

conditions. However, most foods contain enough moisture to permit action by

their own enzymes and by microorganisms, so that to preserve them by drying ,

the removal (or binding ) of moisture is necessary.

Drying is a

mass transfer process

resulting in the removal of water

moisture by

evaporation from a

solid, semi-solid or

liquid to end in a solid

state. To achieve this, there must be a source of

heat, and a sink for evacuation

of the

vapor thus produced. Notice

that any method or technique that reduces the amount of available moisture,

i.e., lowers the water activity (aw), in a food, is

also a form of drying (FRAZIER et al 1988).

Among different methods of drying, sun drying, solar drying,

hot air drying, drum drying, freeze drying and microwave drying are briefly

discussed here as they have been explained by Vieira (1996).

- Sun drying: or natural drying is used in

hot climate, where moisture is removed by exposing foods to the sunrays

without any artificially produced heat and without controlling temperatures,

relative humidity, or air velocity.

- Solar drying: Uses solar energy to produce

heat in an artificial equipment called solar dryer.

- Hot air drying: When mechanical dehydrators

are used, the product to dry is placed on metal mesh belts in a tunnel or in

a cabinet on trays where controlled, elevated temperatures are used. The

air in dehydrators is heated ether by steam tubes or coils, or by being

mixed directly with the combustion gasses of gas or oil. Electric resistance

heaters can be used in some instances. The relative humidity and the air

velocity must also be controlled.

- Drum drying: the products to be dried are

allowed to flow onto the surface of two heated stainless steel drums located

side by side and rotating in opposite directions with little clearance

between them. The product dries on the drums and is scraped off by

stationary blades fixed along the surface of the drum.

-

Freeze

drying: is increasingly applied to dry foods, beyond its already

classical pharmaceutical or medical applications. It keeps biological

properties of proteins, and retains vitamins and bioactive compounds. The

freeze drying is carried out by first freezing the product and then

subjecting it to a very high vacuum, wherein temperatures are high enough to

assist in the evaporation of the moisture but low enough to prevent melting

of the ice in the product. In this method, the water, existing as ice in the

food, is evaporated directly as a vapor without passing through the liquid

phase (sublimation). The vapor evaporated by sublimation is removed from the

system by converting it into ice in a condenser, operating at very low

temperatures, outside the freeze drying chamber.

- Microwave drying: microwaves are used in

different drying applications including dehydration, concentration, and

finish drying where traces of moisture remaining after conventional drying

can quickly be removed from the inner portion of the product without

overheating the already dried product.

In addition to these drying methods, there is also a new one,

called

supercritical

drying or superheated steam drying, which

involves steam drying of products containing water. Strange as it seems, this

is possible because the water in the product is boiled off, and joined with the

drying medium, increasing its flow. It is usually employed in closed circuit

and allows a proportion of latent heat to be recovered by recompression, a

feature which is not possible with conventional air drying, for instance. May

have potential for foods if carried out at reduced pressure, to lower the

boiling point (

www.wikipedia.org/wiki/drying

,29/5/2008).

2.1.3. VEGETABLES

The term "vegetable" generally refers to the

edible part of a

plant. The definition is

traditional rather than

scientific. It is

somewhat arbitrary and subjective, as it is determined by individual cultural

customs of cooking and food preparation.

Vegetables can be either whole plants or only some parts of

plants served with the main course of a meal. Apart from their nutritive value,

vegetables probably do more than any other group of foods to add appetizing

colour, texture and flavour to our daily food. By a proper choice of

vegetables, the desired flavour of meal can be obtained (SHAKUNTALA et al

2001).

2.1.3.i. CLASSIFICATION OF VEGETABLES

According to SHAKUNTALA (2001); vegetables are classified on

the basis of the parts consumed of the plants, such as roots, stems, flowers,

etc. However this may not be satisfactory as some parts of the plants may be

grouped under more than one heading. Hence, vegetables are subdivided into

groups based on their cultural requirements. On this basis, the commonly used

vegetables can be classified as follows:

a. Cole crops: Some examples of vegetables

of this group are cabbage (Brassica oleracea L.var capitata), and

cauliflower( Brassica oleracea L.var. botrytis).

b. Root vegetables: As examples of

vegetables of this group, we can say ; carrot (Daucus carota), and

beetroot (Beta vulgaris).

c. Cucurbits : As examples of vegetables

of this group, we can say; cucumber (Cucumis sativus), and pumpkin

(Cucurbita moschata).

d. Fruit vegetables : These are other

vegetables, apart from cucurbits, for which the edible part is the fruit. As

examples of vegetables of this group, we can say ; tomatoes (Lycopersicon

esculentum), pepper (Capsicum annuum), egg plant ( Solanum

melongena), and chow-chow or chayote (Sechium edule).

e. Green leafy vegetables: The main edible

parts of vegetables of this group are leaves. As examples of vegetables of

this group, we can say; amaranth ( The genus of Amaranthus), celery

( Apium graveolens, L. var duluce), and spinach

(spinacea oleracea).

f. Tuber vegetables: As examples of

vegetables of this group, we can say ; Irish potato(Solanum

tuberosum), sweet potato (Ipomoea batatus), and tapioca or

cassava (Manihot esculenta).

g. Bulbs: In this group of vegetables, the

edible part is the bulb. It contains vegetables such as onions (Allium

cepa), garlic (Allium sativum), and leek ( Allium

ampeloprasum var porrum ).

h. Perennial vegetables: This group contains

a number of vegetables, botanically unrelated, which are similar in that they

are perennials. Some of them are here mentioned as asparagus ( Asparagus

officinalis), and rhubarb ( Rheum rhaponticum).

i. Other vegetables: vegetables in this group

can be broadly classified under the following heads: leguminous vegetables,

drumstick ( Moringa oleifera), mashrooms (genus Agaricus

).

j. Salads: Salads are generally green

vegetables which are eaten uncooked.

2.1.3.ii. NUTRITIONAL COMPOSITION OF VEGETABLES

Vegetables are an important part of the human diet and a major

source of biologically active substances such as vitamins, dietary fiber,

antioxidants, and cholesterol-lowering compounds. Historically, the value of

many plant nutrients and health-promoting compounds was discovered by trial and

error. By the turn of the century, the application of chromatography, mass

spectrometry, infrared spectrometry, and nuclear magnetic resonance allowed

quantitative and qualitative measurements of a large number of plant

metabolites. Approximately 50000 metabolites have been elucidated in plants,

and it is predicted that the final number will exceed 200000. Most of them have

unknown function. Metabolites such as carbohydrates, organic and amino acids,

vitamins, hormones, flavonoids, phenolics, and glucosinolates are essential for

plant growth, development, stress adaptation, and defense. Besides the

importance for the plant itself, such metabolites determine the nutritional

quality of food, color, taste, smell, antioxidative, anticarcinogenic,

antihypertension, anti-inflammatory, antimicrobial, immunostimulating, and

cholesterol-lowering properties. This review is focused on major plant

metabolites that characterize the nutritional quality of vegetables. There are

here divided in primary and secondary metabolites.

2.1.3.ii.a. PRIMARY METABOLITES

Primary metabolites such as carbohydrates, amino acids, fatty acids,

and organic acids are involved in growth and development, respiration and

photosynthesis, and hormone and protein synthesis. Primary metabolites are

found across all species within broad phylogenetic groups, and are produced

using the same (or nearly the same) biochemical pathways.

?Carbohydrates

Carbohydrates in vegetables occur as sugar monosaccharides ,

disaccharides , sugar alcohols , oligosaccharides , and polysaccharides

(starch, pectins). In terms of their physiological or nutritional role,

carbohydrates are often classified as available and unavailable. Available

carbohydrates are those that are hydrolyzed by enzymes of the human

gastrointestinal system to monosaccharides such as sucrose and digestible

starch. Unavailable carbohydrates (sugar alcohols, many oligosaccharides, and

nonstarch polysaccharides) are not hydrolyzed by endogenous human enzymes. The

consumption of high dietary fiber foods has been found to reduce symptoms of

chronic constipation, diverticular disease, and some types of colitis. It has

been suggested that diets with low fiber may increase the risk of developing

colon cancer, cardiovascular diseases, and obesity (HOUNSOME et al

2008 )

?Proteins and amino acids

Proteins provide structural material for the human body and

function as enzymes, hormones, and antibodies. Vegetables contain all essential

amino acids, but some may be in lower proportions than are required for humans.

Besides the importance for human metabolism, free amino acids contribute to the

taste of vegetables (HOUNSOME et al 2008).

? Vitamin B complex

The vitamin B complex of vegetables includes the water-soluble

vitamins thiamine (B1), riboflavin (B2), nicotinic acid (B3, niacin),

pantothenic acid (B5), pyridoxine (B6), biotin (B7), and folic acid (B9).

Vitamin B deficiency can cause polyneuritis (thiamine), cheilosis, angular

stomatitis and dermatitis (riboflavin), pellagra, diarrhea, dermatitis and

dementia (nicotinic acid), seborrhea, glossitis, peripheral neuropathies and

microcytic anemia (pyridoxine), nausea, dermatitis (pantothenic acid, biotin),

and anemia (folic acid). Green leafy vegetables such spinach, Brussels sprouts,

cauliflower, turnip, and lettuce are good sources of B vitamins (HOUNSOME

et al 2008).

? Lipids and fatty acids

Green vegetables such as Chinese cabbage, Brussels sprouts,

watercress, and parsley are known to contain a relatively high proportion of

polyunsaturated fatty acids, primarily in the form of alpha-linolenic acid. The

consumption of monounsaturated fatty acids has been shown to reduce cholesterol

levels and have a beneficial effect on some of the traditional risk factors for

cardiovascular disease and type 2 diabetes (HOUNSOME et al

2008).

? Organic acids

Plants contain citric, acetic, malic, oxalic, succinic,

fumaric, quinic, tartaric, malonic, shikimic, aconitic, ascorbic acid ( Vitamin

C ), and other organic acids. Green vegetables generally contain low

concentrations of organic acids. Ascorbic acid, known as vitamin C, is an

organic acid with strong antioxidant properties. Vegetables rich in ascorbic

acid include spinach, spring onions, cress, cabbage, broccoli, cauliflower,

sweet peppers, peas, and beans. Because vitamin C is a strong biological

antioxidant, it is also linked to the prevention of degenerative diseases such

as cataracts, certain cancers, and cardiovascular disorders (HOUNSOME et

al 2008).

2.1.3.ii.b. SECONDARY METABOLITES

Plants produce a diverse assortment of

organic compounds that do not participate directly in growth and development.

These substances, traditionally called secondary metabolites, are often

differentially distributed among taxonomic groups within the plant kingdom.

Their functions, many of which remain unknown, and are being elucidated with

increasing frequency. But generally secondary metabolites such as flavonoids,

carotenoids, sterols, phenolic acids, alkaloids, and glucosinolates determine

the color of vegetables, protect plants against herbivores and microorganisms,

attract pollinators and seed-dispersing animals, and act as signal molecules

under stress conditions. According to the nomenclature adopted by the British

Nutrition Foundation, plant secondary metabolites can be divided into 4

major groups: phenolic and polyphenolic compounds (about 8000 compounds),

terpenoids (about 25000 compounds), alkaloids (about 12000 compounds), and

sulfur-containing compounds ( HOUNSOME et al 2008 ).

2.1.3.iii. EFFECT OF DRYING ON VEGETABLES

When drying foods, the key is to remove moisture as quickly as

possible at a temperature that does not seriously affect the flavour, texture

and colour of the food. If the temperature is too low in the beginning, micro

organisms may survive and even grow before the food is adequately dried. If the

temperature is too high and the humidity too low, the food may harden on the

surface. This makes it more difficult for moisture to escape and the food does

not dry properly.

Although drying is a relatively simple method of food

preservation, the procedure is not exact. A «trial and error»

approach often is needed to decide which techniques work best. Drying, like all

methods of preservation, can result in loss of some nutrients.

Nutritional changes that occur during drying include:

· Calorie content: does not change, but

it is concentrated into a smaller mass as moisture is removed.

· Fiber: no change.

· Vitamin A: fairly well retained under

controlled heat methods.

· Vitamin C: mostly destroyed during

blanching and drying of vegetables.

· Thiamine, riboflavin, niacin: some

loss during blanching but fairly good retention if the water used to rehydrate

also is consumed.

· Minerals: some may be lost during

rehydration if soaking water is not used. Iron is not destroyed by drying.

For best retention of nutrients in dried vegetables, they

must be stored in a cool, dark, dry place and use within a year ( KENDALL

et al 2006 ).

2. 2. SOME VEGETABLES ( INGREDIENTS ) USED

2.2.1. SPINACH

a. Description: Spinach (Spinacia

oleracea) is a flowering plant in the family of Amaranthaceae. It is

native to central and southwestern Asia. It is an annual plant (rarely

biennial), which grows to a height of up to 30 cm. Spinach may survive over

winter in temperate regions. The leaves are alternate, simple, ovate to

triangular-based, very variable in size from about 2-30 cm long and 1-15 cm

broad, with larger leaves at the base of the plant and small leaves higher on

the flowering stem. The flowers are inconspicuous, yellow-green, 3-4 mm

diameter, maturing into a small hard dry lumpy fruit cluster 5-10 mm across

containing several seeds (

www.wikipedia.org/wiki/spinach,

29/5/2008).

b. Classification

Kingdom: Plantae Division: Magnoliophyta Class:

Magnoliopsida Order: Caryophyllales Family: Amaranthaceae,

Genus: Spinacia Species: S. oleracea

Binomial name Spinacia

oleracea

Figure 2.2.1 : Picture of spinach c. Nutritional

value per 100g

Table 2.2.1

Nutritional value of spinach

2.2.2. POTATOES

a. Description: Potato is the term which

applies either to the

starchy,

tuberous

root vegetable crop

from the various subspecies of the

perennial plant

Solanum tuberosum of the

Solanaceae, or

nightshade, family, or to

the plant itself. There is general agreement among contemporary botanists that

potato species originated in the

Andes, all the way from

Colombia and

Venezuela to

Chile and northern

Argentina, but with a

concentration of

genetic diversity,

both in the form of cultivated and wild species, in the area of modern day

Peru. The evidence thus far

shows that the potato was first cultivated in Peru some 7,000 years ago. The

potato was introduced to Europe around 1700, and subsequently by European

mariners to territories and ports throughout the world. The English

word potato comes from

Spanish

patata (the name used in

Spain). Another common name is

"ground apple": pomme de terre in

French. Potato

plants grow high to the ground and bear yellow to silver

flowers with yellow

stamens. Potatoes are

cross-pollinated mostly

by

bumblebees that carry

pollen from other potato plants, but a substantial amount of self-fertilizing

occurs as well. Any potato variety can also be

propagated

vegetatively by planting tubers, pieces of tubers, cut to include at least

one or two eyes, or also by cuttings, a practice used in greenhouses for the

production of healthy seed tubers (

www.wikipedia.org/wiki/potato

,29/5/2008).

b. Classification

Kingdom:

Plantae

Division:

Magnoliophyta

Class:

Magnoliopsida

Subclass:

Asteridae

Order:

Solanales

Family:

Solanaceae

Genus:

Solanum

Species: S. tuberosum

Binomial

name

Solanum tuberosum

c. Picture

Figure 2.2.2 : Picture of potatoes

d. Nutritional value per

100 g

Table 2.2.1 Nutritional value of potato

2.2.3. LEEK

a. Description: The leek , Allium

ampeloprasum var. porrum (L.), also sometimes known as Allium

porrum, is a vegetable which belongs, along with the

onion and

garlic, to the

Alliaceae family.

Two related vegetables, the

elephant garlic and

kurrat, are also variant

subspecies of

Allium

ampeloprasum, although different in their uses as food. The

edible part of the leek plant is sometimes called a

stem, though technically

it is a bundle of leaf sheaths. Rather than forming a tight bulb like the

onion, the leek produces a long cylinder of bundled leaf sheaths which are

generally blanched by pushing soil around them (trenching)(

www.wikipedia.org/wiki/leek,29/5/2008).b.

classification

Kingdom:

Plantae

Division:

Magnoliophyta

Class:

Liliopsida

Order:

Asparagales

Family:

Alliaceae

Genus:

Allium

Species:

A.

ampeloprasum

Subspecies: A. ampeloprasum var. porrum

Trinomial

nameAllium ampeloprasum var. porrum

Figure 2.2.3 : Picture of leek

2.2.4. PEPPER

a. Description : Yellow pepper (Piper nigrum) is a

flowering

vine in the family

Piperaceae, cultivated

for its

fruit, which is usually dried

and used as a

spice and

seasoning. The same fruit

is also used to produce white pepper, red/pink pepper, and green pepper. Black

pepper is native to

South India and is

extensively cultivated there and elsewhere in tropical regions. The

fruit, known as a peppercorn

when dried, is a small

drupe five millimetres in

diameter, dark red when fully mature, containing a single

seed. Dried ground pepper is

one of the most common spices in European

cuisine and its descendants,

having been known and prized since antiquity for both its flavour and its use

as a

medicine. The spiciness of

black pepper is due to the chemical

piperine. Ground black

peppercorn, usually referred to simply as "pepper", may be found on nearly

every dinner table in some parts of the world, often alongside

table salt (

www.wikipedia.org/wiki/pepper,

29/5/2008).

b. Classification

Kingdom:

Plantae

Division:

Magnoliophyta

Class:

Magnoliopsida

Order:

Piperales

Family:

Piperaceae

Genus:

Piper

Species: P. nigrum

Binomial

name

Piper nigrum

c. Picture

Figure 2.2.4 : Picture of pepper

2.2.5. TOMATOES

a. Description : The tomato (Solanum

lycopersicum) is a

plant in the

Solanaceae or

nightshade family, as are

its close cousins

tobacco,

chili peppers,

potato, and

eggplant. The tomato is

native to

Central,

South, and southern

North America from

Mexico to

Argentina. It is a

perennial, often

grown outdoors in temperate climates as an

annual, typically

reaching to 1-3 m (3 to 10 ft) in height, with a weak, woody stem

that often vines over other plants. The

leaves are 10-25 cm long,

odd pinnate, with 5-9 leaflets on petioles, each leaflet up to 8 cm long,

with a serrated margin; both the stem and leaves are densely glandular-hairy.

The

flowers are 1-2 cm

across, yellow, with five pointed lobes on the

corolla; they

are borne in a

cyme of 3-12 together. The word

tomato derives from a word in the

Nahuatl language,

tomatl. The

specific name,

lycopersicum, means "wolf-peach" (compare the related species

Et.alycocarpum, whose

scientific

name means "wolf-fruit", common name "wolf-apple") (

www.wikipedia.org/wiki/tomato

,29/5/2008).

b. Classification

Kingdom:

Plantae

Subkingdom:

Tracheobionta

Division:

Magnoliophyta

Class:

Magnoliopsida

Subclass:

Asteridae

Order:

Solanales

Family:

Solanaceae

Genus:

Solanum

Species: Et.alycopersicum

Binomial

name

Solanum lycopersicum

Synonyms

Lycopersicon lycopersicum

Lycopersicon

esculentum

c. Picture

Figure 2.2.5 : Picture of tomatoes

Figure 2.2.5 : Picture of tomatoes

d.

Nutritional value per 100 g

Table 2.2.1 Nutritional value of

tomato

2.2.6. CELERY

a. Description : Apium graveolens is

a

plant species in the family

Apiaceae, and yields two

important vegetables known as celery and

celeriac.

Cultivars of the species

have been used for centuries, whilst others have been domesticated only in the

last 200-300 years. The

petiole is main

the part consumed. Apium graveolens is used around the world as a

vegetable, either for the crisp petiole (leaf stalk) or fleshy taproot. In

temperate countries, celery is also grown for its seeds, which yield a valuable

volatile oil used in the perfume and pharmaceutical industries. Celery seeds

can be used as flavouring or spice either as whole seeds or, ground and mixed

with salt, as celery salt (

www.wikipedia.org/wiki/celery

,29/5/2008).

b. classification

Kingdom:

Plantae

Division:

Magnoliophyta

Class:

Magnoliopsida

Order:

Apiales

Family:

Apiaceae

Genus:

Apium

Species: graveolens

Binomial

name

Apium graveolens

c. Picture

Figure 2.2.6 : Picture of celery

d. Celery, raw

Nutritional value per 100 g

Table 2.2.1 Nutritional value of

celery

2.2.7. CARROT

a. Description: The carrot (Daucus

carota subsp. sativus) is a

root vegetable,

usually

orange or white,

or red-white blend in colour, with a crisp texture when fresh. The edible part

of a carrot is a

taproot. It is a

domesticated form of the

wild carrot Daucus

carota, native to

Europe and southwestern

Asia. It has been bred for its

greatly enlarged and more palatable, less woody-textured edible taproot, but is

still the same species. It is a

biennial plant which

grows a rosette of leaves in the spring and summer, while building up the stout

taproot, which stores large amounts of

sugars for the

plant to flower in the second

year. The flowering stem grows to about 1 metre (3 ft) tall, with an

umbel of white flowers.

Carrots can be eaten in a variety of ways. They are often chopped and boiled,

fried or steamed, and cooked in

soups and

stews, as well as baby and pet

foods.

Carrot juice is also

widely marketed, especially as a health drink, either stand-alone or blended

with fruits and other vegetables. The carrot gets its characteristic and bright

orange colour from

â-carotene, which is

metabolised into

vitamin A in humans when

bile salts are present in

the intestines. Massive overconsumption of carrots can cause

hypercarotenemia, a

condition in which the skin turns orange (although effects are less dangerous

than those of vitamin A, which can cause liver damage). Carrots are also rich

in

dietary fibre,

antioxidants, and

minerals. Lack of

Vitamin A can cause poor vision, including night vision, and vision can be

restored by adding Vitamin A back into the diet (

www.wikipedia.org/wiki/carrot,

29/5/200).b. classification

Kingdom:

Plantae

Division:

Magnoliophyta

Class:

Magnoliopsida

Order:

Apiales

Family:

Apiaceae

Genus:

Daucus

Species: D. carota

Binomial

name

Daucuscarota

c. Picture

Figure 2.2.7 : Picture of carrot d. Nutritional value

per 100 g

Table 2.2.1 Nutritional value of

carrot 2.2.8. ONION

a. Description : Onion is a term used by many

plants in the genus

Allium. They are

known by the common name "onion" but, used without qualifiers, it usually

refers to Allium cepa. Allium cepa is also known as the

'garden onion' or '

bulb' onion and '

shallot'. Allium

cepa is known only in cultivation, but related wild species occur in

Central Asia. The most closely-related species include Allium

vavilovii and Allium asarense from Iran. However there are

doubts whether the vavilovii collections tested represent genuine wild

material or only feral derivatives of the crop (

www.wikipedia.org/wiki/onion

,29/5/2008).

b. classification

Kingdom:

Plantae

Division:

Magnoliophyta

Class:

Liliopsida

Order:

Asparagales

Family:

Alliaceae

Genus:

Allium

Species: A. cepa

Binomial

name

Allium cepa

c. Pictures

Figure 2.2.8 : Picture

of onion

d. Nutritional

value per 100 g

Table 2.2.1 Nutritional value of onion

2.2.9. GARLIC

a. Description : Allium sativum

L., commonly known as garlic, is a species in the

onion family

Alliaceae. Its close

relatives include the

onion, the

shallot, and the

leek. Garlic

has been used throughout recorded history for both

culinary and

medicinal purposes. It has

a characteristic pungent, spicy flavor that mellows and sweetens considerably

with cooking. A bulb of garlic, the most commonly used part of the plant, is

divided into numerous fleshy sections called

cloves.

The cloves are used as seed, for consumption (raw or cooked), and for medicinal

purposes. The leaves, stems (

scape) and

flowers (bulbils) on the head (spathe) are also edible and most often consumed

while immature and still tender (

www.wikipedia.org/wiki/garlic ,

29/5/2008 ).

b. Classification

Kingdom:

Plantae

Division:

Magnoliophyta

Class:

Liliopsida

Order:

Asparagales

Family:

Alliaceae

Subfamily: Allioideae

Tribe: Allieae

Genus:

Allium

Species: A. sativum

Binomial

name Allium sativum

c. Picture

Figure

2.2.9 : Picture of garlic

d.Nutritional

value per 100 g

Table 2.2.1 Nutritional value of

garlic

e. Garlic and cardiovascular diseases

Epidemiological, clinical, and laboratory studies have

reported that garlic contains many biologically and pharmacologically active

compounds. The majority of studies show that garlic lowers total serum

cholesterol and LDL-cholesterol; inhibition of HMG-CoA reductase or squalene

epoxidase appears to be the major mechanism. Lowering of blood pressure likely

results from inhibition of angiotensin-converting enzyme activity.

Antithrombosis effects may be related to inhibition of adenosine deaminase.

Antioxidant effects may be related to the inhibition of lipoxygenase. The

published studies in their aggregate suggest that appropriate usage of allium

derivatives from garlic may potentially play a role in the maintenance of

optimal cardiac function. However, further research is needed to examine the

structure-function relationships of the various allium derivatives of garlic,

the amounts in foods and supplements required for efficacy, and the possible

effects of combining garlic with other nutrients and medications.

The mechanisms of action of allium derivatives on

various aspects of cardiac function require further clarification ( MICHELLE

et al, 2000 ).

Chapter Three : MATERIALS AND METHODS

3.1. RESEARCH DESIGN

In conduction of this research, the work was partitioned and

designed as follows:

- Drying of the vegetables: Vegetables were

dried before being grinded and mixed. The drying

operation was done at Kabagali in Ruhango district.

- Food formulation and development: This was

achieved by proceeding as follows:

- Formulation of six different soups and carry out the first

sensory analysis in order to choose one.

( the most appreciated )

- Reformulation of the chosen soup according to the results of

the first sensory analysis, setting a cooking method, and carry out a second

sensory analysis.

- Consumer acceptability check : By the use

of questionnaire, the researcher gave his product

to the selected panelists and checked for consumer

acceptability

- Laboratory analysis: This was done so as to

know the chemical composition, and the nutritive

value of the soup.

- Pricing mechanism : This was done for

checking what would have to be price of the formulated food, so as to know

whether the production of that product would be economically significant or not

and if it would be affordable.

3.2. SOURCE OF RAW MATERIALS

Except tomatoes and potatoes that were bought in Kabagali

market, all other vegetables used as ingredients (carrots, celery, garlic,

leek, onion, pepper, and spinach), were bought in Kimisagara market, trying

to chose the best ones on sight and the most fresh, and then were transported

at ambient temperature up to Kabagali where they were subjected to further

treatments.

3.3. EXPERIMENTAL PROCEDURES

3.3.1. PREPARATION AND DRYING OF THE

VEGETABLES

5 Kg of carrots, 1.5 Kg of celery, 1 Kg of garlic, 1 Kg of

leek, 3 Kg of onion, 1 Kg of pepper, 3 Kg of potatoes, 3 Kg of spinach and 7.4

Kg of tomatoes were weighed with a balance. All these vegetables were then

washed with plenty of water and carrots, onions, potatoes and tomatoes were

peeled with a kitchen stainless steel knife prior to slicing. After that, all

the vegetables were sliced into small size particles with means of a kitchen

stainless steel knife or rape and then put into the hybrid dryer. The

starting and the end time, as well as the temperature inside the dryer were

both recorded.

3.3.2. FOOD FORMULATION AND DEVELOPMENT

3.3.2.i. FOOD FORMULATION PROPOSAL

In formulating the soup, six different types of soups,

which were different in the composition of some ingredients such as

potatoes, carrots and tomatoes, were proposed to people, and these ones were

allowed to evaluate and criticize them.

The main differences were that;

- Soup A was rich in potatoes, but poor in carrots and

tomatoes

- Soup B was medium in potatoes and carrots but poor in

tomatoes

- Soup C was medium in potatoes and tomatoes but poor in

carrots

- Soup D was poor in potatoes, but medium in carrots and

tomatoes

- Soup E was rich in carrots but poor in potatoes and

tomatoes

- Soup F was rich in tomatoes but poor in potatoes and

carrots

The composition of each type of soup is shown in the table

below

|

Composition per soup ( in % )

|

|

Ingredients

|

Soup A

|

Soup B

|

Soup C

|

Soup D

|

Soup E

|

Soup F

|

|

Potatoes

|

50

|

30

|

30

|

10

|

10

|

10

|

|

Carrot

|

10

|

30

|

10

|

30

|

50

|

10

|

|

Tomatoes

|

10

|

10

|

30

|

30

|

10

|

50

|

|

Spinach

|

5.5

|

5.5

|

5.5

|

5.5

|

5.5

|

5.5

|

|

Onion

|

8

|

8

|

8

|

8

|

8

|

8

|

|

Garlic

|

5.5

|

5.5

|

5.5

|

5.5

|

5.5

|

5.5

|

|

Leek

|

5.5

|

5.5

|

5.5

|

5.5

|

5.5

|

5.5

|

|

Celery

|

3

|

3

|

3

|

3

|

3

|

3

|

|

Pepper

|

2.5

|

2.5

|

2.5

|

2.5

|

2.5

|

2.5

|

Table 3.3.2 composition of six

proposed soups

3.3.2.ii. FIRST SENSORY ANALYSIS

Using a questionnaire ( see appendix 1 ), a sensory analysis

was done in order to know and choose one most suitable soup. A selected panel

of ten untrained panelists, was asked to take on each of the six soups and

evaluate them by answering the questionnaire.

Data collected were assessed by analyzing the mean and the

most accepted ( liked ) soup would have to be modified according to the

consumer's suggestions, and taking into consideration the basic scientific

principles.

3.3.2.iii. REFORMULATION AND SECOND SENSORY

ANALYSIS

Based on the results of the first sensory analysis, the

researcher tried to modify the most accepted (liked) soup in order to meet the

consumer preferences. This was done by taking into consideration the

suggestions and recommendations given by the consumers on the first sensory

analysis. For example the quantity of pepper was reduced from 2.5% up to 1%,

and little cooking oil was included during cooking.

For establishing a good and correct cooking time, a second

sensory analysis was carried out.

Three identical samples were prepared and cooked for different

intervals of period and a six untrained panelists tested the three soups and

answered a questionnaire ( see appendix 2 ).

For the first sample, 50g of food were taken, mixed with

800ml of water and 5ml of oil and then cooked for 15

minutes.

For the second sample, 50g of food were taken, mixed with

850ml of water and 5ml of oil and then cooked for 20 minutes.

For the third on, 50g of food were taken, mixed with 900ml of

water and 5ml of oil

and then cooked for 25 minutes.

3.3.3. CONSUMER ACCEPTABILITY CHECK

In order to know whether the researcher has met the consumer

needs and preferences or not, and to be sure that the new product will be sold

on the market, he carried out the consumer acceptability check.

This was achieved by using questionnaire ( see appendix 3 ),

where fifteen untrained panelists were asked to assess all the characteristics

of the product, as well as its packaging and its labeling, and rate them using

a five-point hedonic scale that was provided. The product was firstly evaluated

before being opened, then after opening and lastly after being consumed.

3.3.3.i. STATISTICAL METHODS USED

One Way ANOVA (Analysis Of the Variance) statistical

method, and analysis of the mean, as well as computer software( MS EXCEL ) were

used to analyze the data obtained from sensory evaluation.

3.4.4. LABORATORY ANALYSIS

The soup formulated was analyzed in the laboratory so as to

know its chemical composition, and its nutritive value.

This was so important since, those information would have to

be indicated on the label.

Thus, it was analyzed for the moisture content, ash and

mineral content, carbohydrates, fat content, protein content and Vitamin C

content.

The following are the procedures for all these analysis.

3.3.4.i. MOISTURE CONTENT DETERMINATION

The moisture content of the formulated food was checked in

order to be able to estimate its storage stability and shelf life. It was also

necessary to be checked so as to write its true value on the label.

For this a sample for moisture content determination was sent

to the laboratory of ISAR - Rubona for being analyzed. The procedure used is as

follows.

Different samples of the mixture (formulated food), were

weighed and dried again in the microwave oven, being cooled and weighed at

some intervals of time, until difference became less than 1.0 mg for 30minutes

heating.

By calculation (W1- W2)

the weight of moisture evaporated was determined.

Then, the percentage moisture content was obtained as

follows:

where W1 =Weight of sample before

drying

%Moisture =  W2 =Weight of sample after

drying

W2 =Weight of sample after

drying

3.3.4.ii. ASH AND MINERAL CONTENT

DETERMINATION

As the formulated food had to be packed and well labeled, it

has been necessary to determine its ash and mineral content so as to write the

true value on the label.

For this a sample for ash and mineral content determination

was sent to the laboratory of

ISAR - Rubona for being analyzed. The procedure used is as

follows.

- A laboratory sample of food to be analyzed was weighed

accurately (W1)

- Incinerate the sample by heating it in a muffle furnace on a

temperature of 500°C-600°C,

for a period of 2-5hours

- Cool to room temperature in a desiccator and

weigh.

- Repeat the procedure until difference becomes less

than 1.0 mg for 30 min heating

- Weigh the ash remaining

(W2)

- Carry out the calculations to get the value of ash

content.

%Ash content =

3.3.4.iii. CARBOHYDRATES CONTENT

DETERMINATION

As the formulated food would have to be packed and well

labeled, it was necessary to determine its carbohydrate content so as to write

the true value on the label.

A sample for carbohydrate content determination was sent to

the laboratory of ISAE - Busogo for being analyzed and analysis was done by

Lane-Eynon method (see appendix 4)

3.3.4.iv. FAT CONTENT DETERMINATION

Lipids are one of the major constituents of the foods, and an

important source of energy. Nevertheless, over-consumption of certain lipid

components such as cholesterol and saturated fats can be detrimental to our

health. Because of that, the formulated food has been analyzed for the fat

content and the true value is indicated on the label.

A sample for fat content determination was sent to the

laboratory of ISAR - Rubona for being analyzed.

In order to determine the fat content of the food the soxhlet

method ( see appendix 5) was used .

3.3.4.v. PROTEIN CONTENT DETERMINATION

T he protein content of the food was determined in order to

get true value that will be put on the label.

A sample for protein content determination was sent to the

laboratory of ISAE - Busogo for being analyzed.

The protein content of the food was analyzed by the Kjeldahl

method ( see appendix 6 ).

3.3.4.vi. VITAMIN C CONTENT

DETERMINATION

Vitamin C (in vegetables) is very heat sensitive. Hence, it is

possible that during drying, the vitamin C content of different ingredients may

decrease considerably.

Experiments for determining the vitamin C content of the

formulated food, were carried out in KIST food processing laboratory, by using

the method of Indophenol solution ( see appendix 7 ).

3.5. PRICING MECHANISM

For calculating the average cost of production per unit, all

the expenses made during the research ( cost of ingredients, transport,

energy, and labor ) were calculated as well as the tools and machinery buying

up. Then , the price of the formulated food were estimated by applying a

reasonable benefit margin of 15%.

Chapter Four : RESULTS AND DISCUSSION

A flavoured organic soup was developed as explained in chapter

three. This chapter four , focuses on the results obtained from different

experiments, and from sensory evaluation as well as their discussion.

These results are presented and discussed in the same order as

the steps of the research design.

4.1. DRYING OF THE VEGETABLES

The results obtained from the experiment of drying are

summarized in the table below

|

Vegetable

|

Mass before preparation ( Kg )

|

Mass after preparation & before drying ( Kg

)

|

Mass after drying

( Kg )

|

Water evaporated

( Kg )

|

Drying time

( hours )

|

Drying T°

( °C )

|

|

Carrot

|

5

|

3.80

|

0.36

|

3.44

|

9

|

60

|

|

Celery

|

1.5

|

1.00

|

0.08

|

0.92

|

4

|

|

Garlic

|

1

|

0.82

|

0.26

|

0.56

|

10

|

|

Leek

|

1

|

0.80

|

0.06

|

0.74

|

7

|

|

Onion

|

3

|

2.00

|

0.28

|

1.72

|

6

|

|

Pepper

|

1

|

0.96

|

0.17

|

0.79

|

6

|

|

Potatoes

|

3

|

1.88

|

0.50

|

1.38

|

6

|

|

Spinach

|

3

|

2.60

|

0.18

|

2.42

|

8

|

|

Tomatoes

|

7.4

|

6.00

|

0.48

|

5.52

|

12

|

Table 4.1 results from the experiment of drying

The following is one of the pictures taken after the drying

process

Figure 4.1: dried vegetables

(after the process)

As it can be observed in the table, the drying time was

affected by the initial moisture content, and the structure of vegetables.

That is why tomatoes ( with high moisture content) have a long drying time,

followed by garlic which the structure does not allow easy removal of water.

4.2. FOOD FORMULATION AND DEVELOPMENT

4.2.1. FIRST SENSORY ANALYSIS

From six different soups proposed, a questionnaire was used

for sensory analysis in order to know and choose one most suitable soup.

The table below shows the mean score of the results obtained

by each of sensory attributes assessed for the six soups (in percentage).

|

Score obtained by different soup ( in % )

|

|

Soup A

|

Soup B

|

Soup C

|

Soup D

|

Soup E

|

Soup F

|

|

Appearance

|

54

|

62

|

60

|

62

|

69

|

58

|

|

Aroma

|

55

|

53

|

53

|

55

|

65

|

56

|

|

Colour

|

62

|

60

|

58

|

55

|

66

|

59

|

|

Taste

|

55

|

56

|

58

|

56

|

62

|

57

|

|

Texture

|

56

|

57

|

53

|

53

|

60

|

60

|

|

Overall acceptability

|

49

|

58

|

54

|

57

|

67

|

53

|

Table 4.2.1 results of the first sensory analysis

As you can see in the table, the fifth soup (Soup E) was the

most appreciated with respect to all characteristics, and had a record of 67%

in overall acceptability.

However, at this step, there were also many other suggestions

and recommendations; 69% of the panelists suggested to reduce the quantity of

pepper, 18% wanted it to be removed, while 13% did not say anything about it.

With that 72% of them said that the palatability could be increased by

addition of little cooking oil, and 58% recommended the cooking time to be

lengthened.

4.2.2. REFORMULATION OF THE FOOD AND SECOND SENSORY

ANALYSIS

Based on the results of the first sensory analysis, the most

appreciated food (soup E) was reformulated in order to meet the consumer

preferences.

The final composition of the food formulated was established

as follows:

|

Ingredients

|

Quantity

|

|

Carrot

|

50%

|

|

Potatoes

|

10%

|

|

Tomatoes

|

10%

|

|

Onion

|

8%

|

|

Garlic

|

6%

|

|

Spinach

|

5%

|

|

Leek

|

5%

|

|

Celery

|

3%

|

|

Salt

|

2%

|

|

Pepper

|

1%

|

Table 4.2.2.a : composition of the formulated

soup

The flow chart of the flavoured dry vegetable soup development

was established as follows:

Carrots

Celery

Garlic

Onion

Pepper

Potatoes

Spinach

Leek

Tomatoes

Peeling and / or Slicing

Washing

Packaging

Mixing

Weighing

Drying

Blending

Figure

4.2.2 : flow chart of soup development

After reformulation of the soup that was liked, the researcher

carried out a second sensory analysis for establishing good and correct

cooking method and time.

Three identical samples were prepared and cooked for different

intervals of period as described in chapter three. The following are the mean

score of the results obtained by each of the sensory attributes assessed for

the three soups (in percentage).

|

Score obtained by different soup ( in % )

|

|

Soup1

|

Soup2

|

Soup3

|

|

Appearance

|

96

|

93

|

94

|

|

Aroma

|

75

|

82

|

80

|

|

Colour

|

92

|

90

|

92

|

|

Taste

|

95

|

95

|

89

|

|

Texture

|

87

|

85

|

87

|

|

Overall acceptability

|

94

|

90

|

91

|

Table 4.2.2.b : results of the second sensory analysis

Observations

- The first soup (cooked for 15 min) is the most

appreciated, but 16% of the panelists said that they could still feel

some little undercooked odour.

- The last two soups did not have the same undercooking sign

odour, but also have lost some of the good flavour found in soup1

- The consistence and the taste are almost the same for all

the three soups.

4.3. CONSUMER ACCEPTABILITY CHECK

As discussed in chapter three, In order to know whether the

consumer needs and preferences were met or not, and to be sure that the new

flavoured dry vegetable soup could be sold on the market, the consumer

acceptability check was carried out. This was achieved by using questionnaire

(See appendix 3).

The following are the summaries of the results obtained on

each step.

4.3.3. BEFORE OPENING

Before opening, four attributes ( appearance, aroma, colour

and texture ) were assessed. The following is the table showing the mean scores

of the results obtained by each of those attributes.

|

Attributes

|

Mean Scores

|

|

Appearance

|

4.2666667

|

|

Aroma

|

4.2

|

|

Colour

|

4.2666667

|

|

Texture

|

4.2

|