2.2. Infinite dilution activity coefficients

2.2.1. Definition

The activity coefficient of species in a solution is defined by

the following ratio:

(2-1)

where, is the fugacity of component in solution, its pure

component fugacity and, its

molar fraction. Activity coefficient is also defined as the

proportionality constant between the activity of a substance and its mole

fraction in a given solution.

(2-2)

In the study of phase equilibria and therefore the design and

optimization of separation processes, the concept of activity coefficient is

used rather than activity.

2.2.2. Importance and use of infinite dilution activity

coefficient data

The infinite dilution activity coefficient , also referred to as

limiting activity coefficient is the

limiting value of the activity coefficient of a solute when

its concentration tends towards zero. Alessi et al. (1991) defined the infinite

dilution region as one where each molecule of the solute is surrounded by

molecules of the solvent only. Only solute-solvent interactions take place.

This can be assumed for mole fractions ranging between 10-7 and

10-4, depending on components under investigation. The infinite

dilution region of solutions attracted much interest for couple of reasons

underlining its great importance (Raal and Mühlbauer 1998):

a) The system behavior in the very dilute regions is

instrumental in obtaining high purity products;

b) The most difficult and costly stage of a separation process

is the removal of the last traces of impurity;

c) The greatest departure from ideality occurs in the very

dilute regions;

d) Environmental concerns are based on the very dilute regions

in the gas phase which is air.

Sandler (1996) discusses theoretical and practical

applications of infinite dilution activity coefficient (IDAC) values in

chemical and environmental engineering. The most important ones that are

related to chemical engineering are listed below:

a) Synthesis, design and optimization of separation

processes;

b) Calculation of Henry`s law constants;

c) Predicting the existence of an azeotrope;

d) Development of predictive methods for

e) Characterization of behavior for liquid mixtures.

2.2.2.1. Synthesis, design and optimization of separation

processes

Separation is a critical stage in most of chemical processes

by virtue of its sensitive impact on the global cost, as well as the quality of

the product. One of the most important applications of IDACs is found in

separation processes. IDAC values are used in the preliminary selection of

solvent in view of extractive distillation, as well as, liquid-liquid

extraction (Tiegs et al. 1986). The potentially best separating agent, called

entrainer, is the one allowing the highest selectivity and capacity values. In

other words, when solvents are investigated to find out the most suitable

separating agent for a mixture containing two components and , their respective

IDAC

values in each solvent are determined. Equation (2-3) is then

used to calculate the selectivity at infinite dilution of each solvent with

respect to the system.

(2-3)

and represent the limiting activity coefficients of and

respectively in the solvent,

. is the limiting selectivity of solvent for the system

consisting of components and

. Thus, selectivity values at infinite dilution are important for

a preliminary selection of an

entrainer. A second quantity to look at is the

solvent capacity at infinite dilution, which is

numerically the maximum amount of species that can be dissolved

in the solvent.

(2-4)

Additionally, capacity reveals how much solvent is used during

the separation process. The greater the solvent capacity, the smaller the

amount of solvent used. In principle, the solvent to use as separating agent is

supposed to have the greatest value of both selectivity and capacity. But in

practice, a compromise is to be found, since these two quantities are in

inverse variation with respect to one another. A criterion that incorporates

both selectivity and capacity together

is called performance index, given by the product of these

properties (Kumar and Banerjee

2009). Thus, at infinite dilution,

(2-5)

The determination of permits one to evaluate the potential use of

solvents. Therefore, it

serves as a preselection criterion. Other criteria (Lydersen

1983) leading to the definitive choice of a solvent include: recoverability,

distribution coefficient, solvent solubility, density, interfacial tension,

viscosity, cost, corrosiveness, non-flammability, low toxicity, etc.

2.2.2.2. Calculation of Henry's law constants

There is a relationship between the Henry`s law constant of a

solute in a solvent and its limiting activity coefficient:

(2-6)

represents the Henry`s law constant for solute i in the

solvent and is the vapour pressure

of solute i at the temperature for which the IDAC is

determined. Equation (2-6) shows that

Henry`s law constants can be found

through IDAC values. In cases where the temperature of the

system is above

the critical temperature of the solute, the Henry`s law constant, rather than

the

ln e

8 i

l l 8

IDAC is useful (Eike et al. 2004). Design calculations for gas

separation applications commonly ln e j

involve the use of Henry`s law constants.

2.2.2.3. Predicting the existence of an

azeotrope

Conditions for the occurrence of an azeotrope in binary

systems can be established using infinite dilution activity coefficient data

(Gmehling and Möllmann 1998). For a system showing positive deviation from

Raoult`s law, an azeotrope with a temperature-minimum (pressure-maximum) takes

place when

(2-7) For a system exhibiting negative deviation from Raoult`s

law, an azeotrope with a temperature- maximum (pressure-minimum) takes place

when:

(2-8)

From equations 2-7 and 2-8, it obviously appears that the

knowledge of the IDAC values can help in predicting conditions leading to an

azeotropic mixture.

2.2.2.4. Development of predictive methods

for

Values of infinite dilution activity coefficient are important

for the development of new thermodynamic models, the adjustment of parameters,

as well as the expansion of the applicability for the existing group

contribution models (Gmehling 2003 and Nebig et al. 2009). With the aid of an

appropriate correlation, one can use infinite dilution activity coefficient

values to come up with VLE data in the intermediate concentration range.

Additionally, it is recommended to fit group interaction parameters

simultaneously to all available VLE, LLE and infinite dilution activity

coefficient experimental data (Weidlich and Gmehling 1987).

2.2.2.5. Characterization of behavior for liquid

mixtures

The infinite dilution activity coefficient value is an

indication of the nature of interactions between solute and solvent molecules

(McMillan and Mayer 1945). A high IDAC value is synonymous of weak

solute-solvent interactions i.e. low solubility (Cheong 2003). The IDAC value

is also a limiting measurement of the nonideality (Bao and Han 1995) of a

solution. For an

E

? ? G RT

E

? ?

/ ? H

ideal system, whereas a departure from ideality corresponds to

IDAC values greater or

RT 2

?? = T ??

smaller than unity.

2.2.3. Temperature dependence of activity

coefficient

The Gibbs-Helmholtz equation (2-9) depicts the effect of

temperature change on activity coefficient.

This leads to the following significant relations:

(2-10)

(2-11)

Using experimental ã8 data, the partial excess

enthalpy at infinite dilution for a given solute i,

can be directly obtained from the slope of a straight line

derived from equation (2-11), where is the gas constant. It only takes an

approximation of experimental values by the linear regression,

(2-12)

This procedure is widely used in the experimental section of this

thesis.

2.2.4. Predictive activity coefficient models

Predictive thermodynamic models are very important in separation

processes (Lei et al. 2008) as they allow:

a) A rapid solvent selection at reduced costs (Novak et al.

1987);

b) Accessing data that are difficult or impossible to obtain

experimentally;

c) The development of process simulators (Gmehling 2003).

It is beyond the scope of this study to review all the

thermodynamic models used to predict infinite dilution activity coefficients.

Only the most promising models used for systems involving ionic liquids are

dealt with in this section. The most successful models used by various

researchers to predict activity coefficients of various solutes in ionic

liquids can be classified into two categories:

a) Group contribution methods;

b) COSMO-based methods.

2.2.4.1 Group Contribution methods. (GCMs)

These methods are based on the group contribution concept

which assumes that the interaction energy of a system is the sum of functional

groups interaction energies, provided that groups are properly defined

(Gmehling 2009). Molecules are therefore split into smaller structures called

groups to which parameters are assigned. These activity coefficient models are

mostly based on the relationship between the latter and the excess free

energy.

The ASOG (Analytical Solution of Group) Model

The ASOG (Analytical Solution of Group) model was developed by

Derr and Deal (1969) who exploited previous works by Wilson and Deal (1962). It

was redefined by Kojima and Tochigi (1979) who modified several parameters in

order to account for the effect of temperature changes. In this method, the

expression of the activity coefficient is composed of two parts: the size

contribution term and the group interaction one. Go et al. (2007) used the ASOG

model to correlate experimental infinite dilution activity coefficient data of

n-octane, n-nonane and ndecane in the ionic liquid

4-methyl-n-butylpyridinium tetrafluoroborate in the temperature range

from 297 to 344 K. Their results were in good agreement with the experimental

measurements. Twelve interaction parameters related to three structural groups,

CH2, pyridinium and BF4 were determined.

The UNIFAC model and its modifications

After its publication by Fredenslund et al. (1975), the UNIFAC

(Uniquac Quasi-Chemical Functional Activity Coefficient) underwent a plethora

of revisions and extensions which are outlined in reviews by Lei et al. (2008)

and Castells et al. (1999).

The original UNIFAC, as stated by Lohmann and Gmehling (2001),

presented the following advantages:

a) Availability through commercial processes simulators;

b) Reliability in predicting VLE results;

c) Applicability over a wide range of mixtures.

The same authors highlight its weaknesses as follows:

a) Incorrect description of the temperature-dependence of the

activity coefficient and other related properties;

b) Unsatisfactory results when predicting properties in the

dilute region, as well as for asymmetric systems.

In an attempt to remedy these limitations, more advanced

versions of the UNIFAC model were developed, the most important ones being

UNIFAC (Dortmund) by Weidlich and Gmehling (1987) and UNIFAC (Lynby) by Larsen

et al. (1987). The modified UNIFAC (Dortmund) differs from the original UNIFAC

model in that it uses a different combinatorial part and it reliably takes into

account the temperature dependence of group interaction parameters. Its

developers introduced new van der Waals quantities as well. No thermodynamic

model can claim as much popularity as UNIFAC (Do). This is attributed to the

amount of research work and publications related to it in the last twenty

years. Moreover, around fifty companies and

institutions work actively in the UNIFAC Consortium to support

directly or indirectly its perfections. The Thermodynamics Research Unit, at

the University of KwaZulu-Natal is part of this organization. Successes

recorded in improving the predictability of properties using UNIFAC (Dortmund)

are presented in publications by Gmehling and Schiller (1993), Hansen et al.

(1991), Gmehling (1995), Gmehling et al.(1998), Gmehling et al.(2002), Gmehling

et al.(2009), Lohmann and Gmehling (2001), Wittig et al.(2001) and Jakob et al.

(2006). Recently, Prof. Gmehling`s group started to assess the predictive

ability of UNIFAC (Do) for systems involving ionic liquids. The parameter

matrix of this model has been expanded, allowing for the prediction of infinite

dilution activity coefficients of:

a) n-alkanes and alk-1-enes in [BMPyr] [BTI], [HMPyr] [BTI] and

[OMPyr] [BTI] (Nebig et al. 2009);

b) Methylcyclohexane and toluene in [HMIM] [BTI] (Liebert et al.

2008);

c) n-alkanes, benzene and toluene in [MMIM] [BTI] [BMIM] [BTI]

[HMIM] [BTI], as well as benzene and toluene in [BMIM] [BTI] (Nebig et al.

2007);

? ? d ?

d) n-alkanes, alk-1-enes, cycloalkanes, cycloalkenes, aromatics,

alcohols, ketones, esters, ethers and water in [HMIM][BTI], [OMIM][BTI],

[BMPyr][BTI];

e) The binary mixture of [BMIM] [BTI] and [EMIM] [BTI] (50:50

weight percent) (Kato and Gmehling 2005b).

It is clear that the parameter matrix remains very limited

when one looks at the number of ions involved in the structure of ionic

liquids. The major weakness of GCMs is their inability to deal with isomers,

proximity effects and systems involving groups for which experimental data have

never been compiled (Putnam et al. 2004).

2.2.4.2. COSMO-based methods

The conductor-like screening model (COSMO) is a predictive

method for thermophysical properties using a quantum chemical approach. Its two

most widely used variants for infinite dilution activity coefficients in ionic

liquids are COSMO-RS (The conductor-like screening model for real solvents),

developed by Klamt (1995) and COSMO-SAC (The conductor-like screening model,

solvation activity coefficients) (Lin and Sandler 2002). These two models

involve statistical thermodynamics, along with quantum chemical calculation

(Eckert and Klamt 2003). They require -profiles of molecules in the same manner

as group contribution methods rely on group interaction parameters. A -profile

is defined by Klamt and Eckert (2000) as a distribution function of the amount

of surface having a screening charge density between and

?. COSMO-based models are parameterized for 9 elements so far:

hydrogen, carbon, nitrogen, oxygen, fluorine, chlorine, bromine, iodine and

sulfur. They rely on a very small

number of parameters (Eckert and Klamt 2003) which are not

specific regarding molecules types or functional groups. This represents a

great advantage as compared to GCMs which involve a large number of functional

groups. Even components that have never been synthesized before can be studied

since no experimental data are needed to carry out predictions as shown by

Klamt et al. (1998). Long computation time and high computation costs are the

major disadvantages of these COSMO-based models. In a paper discussing

comparisons between COSMO-RS and GCMs, Grensemann and Gmehling (2005), taking

into account another article to which Klamt himself contributed (Putnam et al.

2004) reveal the following:

a) COSMO-RS achieves poor results in the applicability limits of

GCM`s, more especially, UNIFAC (Do);

b) COSMO-RS is advisable in cases of unknown GCMs parameters,

isomer and proximity effects.

This paper prompted a strong reaction from the developer of

COSMO-RS (Klamt 2005) who found its conclusions biased in order to clearly

favour the Modified UNIFAC (Do). From a neutral point of view, more time is

required to confirm whether COSMO-RS is inferior or superior to GCMs (Klamt and

Eckert 2008). More importantly, extensions are under way to improve both

models. Infinite dilution activity coefficients of a large spectrum of solutes

in some ionic liquids have been predicted using COSMO-RS. In a study on the

removal of thiophene from diesel oil (Kumar and Banerjee 2009), COSMO-RS

predictions of infinite dilution activity coefficient of alkanes, alk-1-enes

and cycloalkanes in [HMIM] [PF6], [HMIM] [BF4], [MOIM] [Cl] and [EMIM] [Tf2N]

are reported. The average absolute deviation of their predictions was found to

be 12% with respect to experimental data. Larger errors are observed in a

quantum chemical approach work by Sumon (2005) when predicting of toluene

and

heptane in a large number of ionic liquids. Other similar

predictive works (Banerjee and Khanna 2006, and Lei et al. 2007b) were in fair

agreement with experimental measurements, exhibiting the same range of

errors.

2.2.5. Experimental techniques for IDACs

measurements

Various experimental methods exist for determining infinite

dilution activity coefficients:

a) Gas-Liquid Chromatography (Letcher 1980);

b) Inert Gas Stripping Method (Leroi et al. 1977 and Richon et

al. 1980);

c) Headspace Analysis Method (Hussam and Carr 1985);

d) Indirect Headspace Chromatography. (Li and Carr 1993);

e) Dew Point Method (Eckert and Sherman 1996);

f) Differential Static Cell Method (Alessi et al. 1986);

g) Differential Ebulliometry Method (Gautreaux and Coates

1955);

h) Rayleigh Distillation Method (Dohnal and Horakova 1991).

The two methods used in this work, are the most popular ones

for ionic liquids. They are discussed here, with an emphasis on their

suitability for this class of solvents. A useful review paper by Kojima et al.

(1997) gives more details on other experimental techniques used for direct IDAC

measurements.

2.2.5.1. Gas liquid chromatography (GLC)

In this technique, the solvent, used as stationary phase, is

loaded onto the column. The solute, which is the mobile phase, is injected in a

carrier gas through the column. The eluted solute is detected and its retention

time, along with other experimental parameters, is used in an equation to

compute the IDAC. Gas-liquid chromatography can be used for IDACs of volatile

solutes in non-volatile or low volatility solvents. It is not applicable to

systems involving a mixture of solvents. Table 2-4 summarizes the advantages

and disadvantages of Gas-Liquid Chromatography.

Table 2-4: Advantages and disadvantages of the

Gas Liquid Chromatographic method

Advantages Disadvantages

Sample purity is not required The method is suited to low

volatility

or non-volatile solvents only

The method is rapid as many solutes can be injected at once

Reactive systems can be investigated

The IDAC of the solvent in the solute cannot be determined

2.2.5.2. The inert gas stripping technique.

(IGS)

In this method, a highly dilute solute is stripped from a

solution by a constant inert gas flow under isothermal conditions. The vapour

leaving the cell is periodically analyzed by gas chromatography. It is observed

that the peak area depicting the solute concentration in the vapour phase

decreases exponentially with time. Under this particular condition of

exponential dilution, the infinite dilution activity coefficient of the solute

in the solvent is related to the

decreasing rate of its corresponding peak area with time. The IGS

method is used to measure

of volatile solutes in non-volatile or volatile solvents.

Systems with solvent mixtures can be

investigated. The method is

alternatively called the dilutor technique, as well as continuous gas

extraction technique (Vitenberg 2003; Dobryakov and Vitenberg

2006). Table 2-5 presents the advantages and disadvantages of this

technique.

Table 2-5: Advantages and disadvantages of the

inert gas stripping method

Advantages Disadvantages

GC calibration is not required since only peak area ratios are

involved in calculations

A mixture of solvents can be investigated.

Systems with high volatility solvents can be measured

Many solutes can be investigated at once

Solutes must be purified.

Low volatility solutes are difficult to measure.

A good gas-liquid contact is critical to obtain reliable

results.

2.3. Advances in the design of IGS equipment 2.3.1. Major

developments in the use of the IGSM

Since its establishment by Leroi et al. (1977), the IGSM

underwent some improvements in terms of modernization of the analytical tool

(GC), temperature and pressure sensors, achievement of isothermal conditions

during experiments, etc. But the most important advance in this technique lies

in a better understanding of factors affecting the accuracy of measurements

provided by many research works. This resulted in various cell designs in order

to suit different types of systems. Bao and Han (1995) sum up the major

advances in the inert gas stripping technique as follows:

a) Establishment of the IGS technique by Leroi et al. (1977);

b) Correction by Duhem and Vidal (1978) for the liquid

concentration of the solute by taking into account its partition between the

two phases in the dilutor cell;

c) Modification of the dilutor cell structure by Richon and

coworkers (Richon et al. 1980 and Richon and Renon 1980);

d) Use of the two-cell technique in order to investigate low

boiling solvents. (Doleúal et al. 1981, and Doleúal and Holub

1985);

e) Extension of the technique to viscous or foaming systems by

Richon et al. (1985);

f) Further extension to mixtures containing food or oil

(Lebert and Richon 1984a, b). More recent developments involve the liquid

analysis gas stripping method (Hradetzky et al. 1990), the use of the inert gas

stripping technique for systems with ionic liquids ( Krummen et al. 2002) and

its extension to more delicate solvents of environmental interest involving

semi-volatile and surface tension solutes (Kutsuna and Hori 2008).

2.3.2. The number of cells required for IDAC

measurements

Either one or two cells can be used to measure infinite

dilution activity coefficients by the inert gas stripping method. The single

cell technique is suitable for systems with low volatility solvents and

relatively high volatility solutes. The double cell technique is required when

the solvent is a high volatile compound or mixture. In this variant, a

presaturation cell is used to saturate the stripping gas with the solvent

before the solute stripping process. This prevents any transfer of the solvent

from the liquid to the vapour phase which would lead to changes of the amount

of solvent in the dilutor cell. The single cell technique is appropriate to

systems involving ionic liquids since they are generally very high boiling

compounds and non volatile. Krummen et al. (2002) reported infinite dilution

activity coefficient data for n-alkanes and alk1-enes, cyclic hydrocarbons,

aromatic hydrocarbons, ketones, alcohols, and water in the ionic liquids

1-methyl-3-methylimidazolium bis (trifluoromethylsulfonyl) imide, 1-ethyl-3-

methylimidazolium bis (trifluoromethyl sulfonyl) imide,

1-butyl-3-methylimidazolium bis (trifluoromethylsulfonyl) imide, and

1-ethyl-3-methylimidazolium ethylsulfate in the temperature range between

293.15 K and 333.15 K. Activity coefficients at infinite dilution of alkanols

in the ionic liquids 1-butyl-3-methylimidazolium hexafluorophosphate,

1-butyl-3- methylimidazolium methylsulfate, [BMIM][MeSO4], and

1-hexyl-3-methylimidazolium bis(trifluoromethylsulfonyl) imide, [HMIM][Tf2N],

were measured by Dobryakov et al (2008). Using the same method, Nebig et al.

(2009) determined for n-alkanes and alk-1-enes in the

ionic liquids 1-butyl-1-methylpyrrolidinium bis

(trifluoromethylsulfonyl) imide, 1-hexyl-1- methyl pyrrolidinium bis

(trifluoromethylsulfonyl) imide and 1-methyl-1-octylpyrrolidinium bis

(trifluoromethylsulfonyl) imide. Kato and Gmehling (2005a, b) presented

infinite dilution activity coefficient data for seven solutes in the ionic

liquids 1-butyl-3-methylimidazolium bis (trifluoromethylsulfonyl) imide and

1-ethyl-3-methylimidazolium bis (trifluoromethylsulfonyl) imide using the

methods of gas liquid chromatography and the inert gas stripping technique.

Their results show a good agreement between the two methods.

2.3.3. Cell design parameters

Thermodynamic equilibrium between the gas leaving the dilutor

cell and the remaining liquid is instrumental in obtaining accurate infinite

dilution activity coefficient data.To achieve this, three conditions must be

met (Leroi et al. 1977):

a) Large total mass transfer area;

b) Sufficiently long contact time;

c) Good dispersion of bubbles in the liquid.

Studies mentioned in the two previous sections threw light on

these factors which affect the

performance of the IGSM:

a) Dispersion device;

b) Bubble rise height;

c) Stripping gas flow rate;

d) Bubble size;

e) Liquid viscosity;

f) Range of IDACs to be measured.

For accurate measurements of IDAC, it is essential to take

into account these factors when designing dilutor cells. The impact of each of

these parameters is briefly explained in the light of expressions derived by

Richon et al. (1980) which are reviewed in Chapter 3 of this thesis.

2.3.3.1. Dispersion device

In the original version of the method by Leroi et al (1977)

(See Figure 2-2), a fine porosity fritted glass was used as dispersion device.

Recently constructed dilutor cells are generally provided with stainless steel

capillaries with very small inner diameters. Stainless steel is known as a non

corrosive material. To ensure that the total mass transfer area is large, the

inert gas, generally helium or nitrogen, is dispersed into very small bubbles.

Capillaries must be in reasonable number and well spaced to avoid any bubble

coalescence. Dobryakov et al. (2008) designed a very small cell, of volume 5

cm3, with just a single capillary tube used as the dispersion

device.

2.3.3.2. Bubble rise height

The liquid level in the cell must be high enough for

sufficient contact time between the bubbles and the investigated solution. This

is a very important condition in view of attaining the required thermodynamic

equilibrium.

2.3.3.3. Stripping gas flow rate

Efficient solute mass transfer from the liquid phase to the

gaseous phase requires low inert gas flow rates as this results in longer

contact times. The optimum flow rate depends on the system under investigation.

It has been shown that when thermodynamic equilibrium has been attained between

the two phases inside the dilutor cell, measured infinite dilution activity

coefficients do not depend on the flow rate value. Additionally, the size of

bubbles is affected by the flow rate, increasing up when the flow rate is

increased. In previous works, experiments were performed with inert gas flow

rates ranging between some tenths to tens of cm3 (Kutsuna and Hori

2008, and Krummen et al. 2002)

2.3.3.4. Bubble size

The smaller the bubble size, the more efficient is the mass

transfer. In effect, when the inert gas is dispersed into the solution as small

bubbles, the total mass transfer area is increased. If bigger bubbles are used,

the height of the cell must be high enough to ensure a long residence time of

the gaseous phase in the solution.

2.3.3.5. Liquid viscosity

A high viscosity hinders mass transfer. Its other effect

consists of reducing the bubble rise and consequently allowing larger contact

times. The two effects with regards to mass transfer and equilibrium conditions

in the cell compensate each other. However, more sophisticated features need to

be incorporated in the design of the dilutor cell, more especially its stirrer,

for very viscous mixtures (Richon et al. 1985).

2.3.3.6. Range of IDACs to be measured

When very high infinite dilution activity coefficient values

have to be measured, large amounts of solute are stripped out of the solution

in a very short period of time, since there are very weak interactions between

the components involved in the mixture. If care is not taken, this will

compromise the attainment of equilibrium and reduce the mass transfer extent as

the contact time may be insufficient. It is not therefore surprising that the

worst agreement between infinite dilution activity coefficient data obtained

with the GLC method and the dilutor technique were observed for very high

activity coefficients (Leroi et al. 1977). The designer should take into

account the range of IDACs values the cell is supposed to deal with in order to

tune other parameters such as the height and the dispersion device.

2.3.4. Review of previous equilibrium cells

Various cell designs have been reported over the last forty

years as part of the inert gas stripping set up for the determination of

infinite dilution activity coefficient, Henry`s law constant and partition

coefficient. The most efficient ones, taken from the open literature are

reviewed. The various researchers who designed the cells discussed in this

section reported a good agreement with infinite dilution activity coefficient

data obtained by the GC method. And, reproducibilities better than 2% were

obtained. However, the reliability seemed to be compromised when very

high values had to be measured. The other issue of concern is the

determination of in

viscous mixtures.

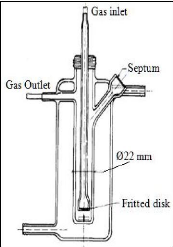

2.3.4.1. Leroi et al. (1977)

Leroi et al. (1977) used the pyrex glass cell represented in

figure 2-2 to measure infinite dilution activity coefficient for n-hexane and

benzene in ten different nonvolatile solvents, including Nmethyl-2-pyrrolidone

(NMP), dimethylsulfoxide (DMSO), dimethylformamide (DMF), nitrobenzene,

ethylene glycol and hexadecane. A solution of volume 25 cm3

could be accommodated by the still and an experiment lasted one to two hours.

Solutes were introduced into the cell by means of a 10 syringe via the septum.

Inert gas flow rates ranged from 50 to

150 cm3 .min-1. To ensure accurate

measurements, liquid drop entrainment was limited by a dead space above the

solution. This gas phase volume was kept small enough to ensure accurate

measurements. The dispersion device consisted of a fine porosity fritted glass

disk as mentioned previously.

Figure 2-2: Dilutor cell constructed by Leroi et

al. (1977)

2.3.4.2 Richon et al. (1980)

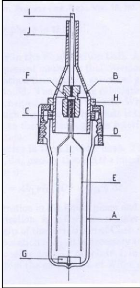

Richon et al. (1980) designed the dilutor cell shown in figure

2-3, similarly to the one constructed by Leroi et al. (1977). Their major

improvements to the first cell include the following features:

a) Equal sized bubbles are introduced from the bottom by means

of fine capillaries;

b) A conical outlet gas collector is adopted to minimize liquid

entrainment.

They investigated infinite dilution activity coefficients of

alkanes from C1 to C9 in hexadecane. Experiments undertaken concluded that the

inert gas stripping method could be easily extended to Henry`s law constant

measurements. For Henry`s law constants greater than 30 atm., their work showed

the necessity to keep a very small and homogeneous vapour phase in the cell.

Figure 2-3: Equilibrium cell constructed by

Richon et al. (1980)

A - glass still body, B - conical collector of gas

outlet, C - gasket, D - plug, E - capillaries, F -

Teflon seal, G - magnetic

stirrer, H - metallic ring used to adjust the depth of the conical

collector

B in the still, I - tube for carrier gas inlet, J - gas outlet.

2.3.4.3. Richon and Renon (1980)

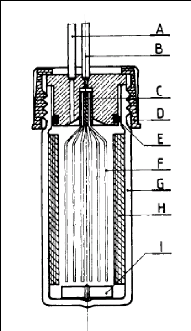

In this design, Richon and Renon (1980) abandoned the previous

conical shape in favour of a simpler shape as shown in figure 2-4. A

considerably reduced 1 cm high gas phase is kept above the solution inside the

dilutor cell. Their cell was used to determine infinite dilution activity

coefficients of light hydrocarbons in n-hexadecane, n-octadecane and 2, 2, 4,

4, 6, 8, 8- heptamethylnonane.

Figure 2-4: Dilutor cell used by Richon and

Renon (1980).

A - vapour phase outlet, B - inert gas inlet, C - Teflon seal,

D - plug, E - O-ring, F -

capillaries, G - glass still body, H - baffles, I

-magnetic stirrer.

2.3.4.4. Legret et al. (1983)

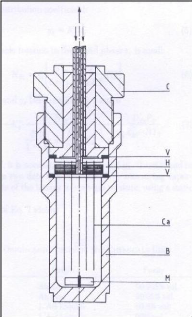

Legret et al. (1983) used the cell below (figure 2-5) to

determine partition coefficients which are related to activity coefficients at

infinite dilution. Their study involved some alkanes as solutes in the

methane/n-decane system. The pre-saturator and the dilutor cell were fitted

with 20 and 50 capillaries respectively. The capillary inner diameter was 0.3

mm for the pre-saturation cell and 0.1 mm for the dilutor cell. Both cells

contained 40 cm3 of solvent.

Figure 2-5: Dilutor cell design by Legret et al.

(1983)

B - body, C - cap, Ca - capillaries, H - capillary holder, M -

magnet, V - O?-ring

|