|

GHENT UNIVERSITY

FACULTY OF PHARMACEUTICAL SCIENCES

LABORATORY OF PHARMACEUTICAL TECHNOLOGY

___________________________

Academic year 2002-2003

AN IN VITRO STUDY OF THE QUALITY OF ESSENTIAL DRUGS

AVAILABLE ON THE RWANDAN MARKET

Thesis submitted to Ghent University, Belgium, in partial

fulfilment of the

requirements for the degree of Master in Pharmaceutical

Sciences (M. Pharm)

By

Pierre Claver KAYUMBA (B.

Pharm.)

Faculty of Sciences and Technology, Department of Pharmacy,

National University of Rwanda, Butare-Rwanda.

Promoters:

Prof. Dr. Apr. J.P. REMON

Prof. Dr. Apr. C. VERVAET

This work is dedicated to my lovely wife Verdiane and to

our beloved children Audrey, Gabin and Jean Marc, for their love, patience,

understanding and care.

Acknowledgements

At the end of this thesis, I would like to express my

gratitude to the government of Rwanda (GOR) for the provision of a scholarship

to support my studies in Belgium.

I wish to thank Prof.Dr. J.P. Remon, for accepting me in

his laboratory and promoting this work. His encouragement, inspiration and

moral support were very important in the accomplishment of this work.

I am also grateful to Prof.Dr. C. Vervaet for his advice

and support towards the realisation of this work.

My appreciation goes to Prof.Dr. W. Baeyens and Prof.Dr.

J. Demeester for their lectures, which were very useful in my research

work.

Thanks to Pharm. D. Ameye for his guidance and assistance

in the various analytical methods.

I am grateful to Dr. J.D. Ntawukuliryayo for his advice,

kindness and sympathy in carrying out my study.

My gratitude goes to Pharm. E. Bienvenu for his critical

comments, which contributed to the final form of this thesis.

My sincere thanks to the Laboratory of Pharmaceutical

Technology for their hospitality and support. Especially, I thank D. Tensy, M.

De Meyer, K. Wullaert, and B. Vandenbussche for their invaluable

assistance.

I wish to thank my colleagues, master students A. Dukic,

A. Eltraplsi and K. W. Mwamwitwa for their useful moral and technical support,

advices and suggestions in the realisation of this work.

I extend special thanks to my wife Verdiane, my daughter

Audrey, my sons Gabin and Jean Marc, for their love, courage, patience and

understanding that made ever possible the realisation of this work.

Thanks to all Rwandan people resident in Ghent or

Brussels, who have contributed to this thesis in many different ways.

Pierre Claver KAYUMBA

September, 2003

I. Introduction, Background, and Objectives

I.1 Introduction

The World Health Organization (WHO) passed in 1975 a

resolution (WHO 28.66) which marked the birth of the Essential Drugs Concept

(EDC). The aim was to solve the problem of accessibility to drugs by the

population in developing countries. In most developing countries people lack

access to drugs because they are expensive and the purchase capacity is very

low. The idea behind the EDC is the recognition that only a few drugs are

necessary for the treatment of the majority of the diseases facing the majority

of the population. In 1977 a model list of Essential Drugs was established, the

criteria of including a drug in the list were: established safety and efficacy,

proven quality, constant availability and affordability. The WHO encouraged all

nations to establish their own Essential Drug List based on the above criteria.

The Rwandan government through the Ministry of Health established its first

national essential drug list in 1991. The principe was that all drugs included

should be, if possible, generics which are cheap and the health workers

(governmental as well as private) were recommend to refer to that list when

prescribing and dispensing. The list was reviewed in 1997 and 1999 and the last

revision was this year.

Counterfeiting of pharmaceuticals and the proliferation of

substandard drugs constitute a serious health risk to the consumers around the

world. The WHO records show that problems of substandard and counterfeit drugs

are on the increase as 50% of all reported cases occurred in the period 1993 to

1997. Most of these incidences (70%) were reported in developing countries. The

report identified the cause of the poor quality of drugs: in about 50% of all

cases the formulations did not contain any drug, 20% contained the wrong active

ingredient and 10% the wrong amount of active ingredients. In another 5% of the

reported incidences did the formulation contain the right active ingredient in

the correct amount, but were judged substandard by failing in other quality

tests. The antibiotics were the major pharmacological class of drugs with the

largest incidence (60%) of counterfeiting (WHO, 2000). According the

International Federation of Pharmaceutical Manufacturers Association (IFPMA)

about 7% of all drugs being sold around the world in 1992 were of poor quality:

being counterfeit or substandard.

In Rwanda

there are no facilities for quality control of pharmaceuticals, no systematic

monitoring of the quality of drugs on the market. This gross deficiency

increases the risk that the importers of pharmaceuticals would go for cheap

possibly low quality products because the substandard products would not be

detected.

After the genocide, the Rwandan pharmaceuticals market is

characterized by the presence of many generics from multisource suppliers and

healthcare providers. Consequently clinicians and pharmacists are faced with

selecting a product that gives the same clinical effect than that claimed to do

so. In most of cases this selection is based on economical considerations and

on the assumption that those dosage forms containing the same amount of active

ingredient are the equivalent.

In addition, there are wide price differences between

formulations containing the same amount of active ingredient (even more than

500%); subsequently patients with low purchasing power will go for cheap

brands. With such differences in price it is essential to know if those brands

are really pharmaceutically equivalent, or if there is a relationship between

price and quality.

I. 2 Background

The quality of pharmaceutical products has been a major

concern in many WHO forums. The existence of counterfeit and substandard drug

preparations, which are of unacceptable quality, incited many studies about the

quality of pharmaceuticals available in different countries. The quality of the

pharmaceuticals in the market depends much on the manufacturer and purchaser's

integrity. Through several studies done, it has been shown that the regular

surveillance on the quality and bioavailability of the formulations marketed in

a country is very important.

Even in developed countries where the pharmaceutical market is

highly controlled and strictly regulated, it was possible to find substandard

drugs in the market:

- The National Medicine Control Laboratory of

Finland reported on the quality and bioequivalency of different brands of

erythromycin tablets: the bioavailability of one brand being very low (Venho et

al., 1987). In the same laboratory Eranko et al. (1990) noticed differences in

bioavailability between different brands of nifedipine tablets. In all

occasions the low availability brand had to be withdrawn from the market.

- In studies done in Canada involving 229

generic brands, 9% were identified to be of an unacceptable standard (Maddock,

1986).

In developing countries, Rwanda included, the control and

regulation of pharmaceuticals is not very strict and there have been many

reports of substandard as well as fake drugs on the market:

- Studies done in Nigeria to evaluate the quality of quinine

tablets reported the presence of fake formulations (Sowumni et al., 1994).

- A report on the quality of pharmaceuticals in developing

countries was made by Shakoor et al. (1997) on 81 drugs sampled from Nigeria

and 15 from Thailand, antimalarials and antibiotics commonly used in these

countries. They analyzed by HPLC the content of the active ingredient as well

as the presence of impurities and degradation products. The results showed that

36% (25) of the samples from Nigeria and 40% (6) from Thailand did not comply

with pharmacopoeia standards and 3 of the substandard samples from Nigeria (2

chloroquine and 1 amoxicillin) and 3 from Thailand (chloroquine) were fake.

Through these observations the authors concluded that the major reason for

substandard drugs in the developing countries was poor manufacturing

practice.

- Sulfamethoxazole, an active pharmaceutical ingredient

manufactured in India, was found to be of poor quality and rejected, but was

deliberately being placed at the bottom of every fourth drum ready to be

exported abroad (WHO, 1997).

- Recently, in the Laboratory of Pharmaceutical Technology of

Ghent University, a study on the quality of essential drugs available on the

Tanzanian market was done by Risha et al. (2002). They evaluated the in vitro

availability and its stability under simulated tropical conditions of 22

formulations containing paracetamol, acetylsalicylic acid, chloroquine and

sulfadoxine/pyrimethamine. They used methods specified in the USP 24 monographs

of the respective drugs. All drugs analyzed passed the pharmacopoeia

requirements for the drug content. However seven formulations failed to meet

the USP 24 tolerance limits for dissolution. In addition five formulations

failed to meet the USP 24 tolerance limits for dissolution after being

subjected for six months to an accelated stability test under simulated

tropical conditions (75 % RH, 40 °C). They concluded that the dissolution

behaviour of 12 of the samples was not satisfactory.

They recommended the validation of the manufacturing process

and the use of excipients with predetermined properties.

I.3 Objectives

Main objective

Since there are no reports about the quality of

pharmaceuticals in Rwanda, this study was undertaken to evaluate the quality of

some essential drugs marketed in Rwanda. The main objective of this study is to

assess the quality of some essential drugs available on the Rwandan market

through the USP 24 requirements. Furthermore to check their stability under

simulated tropical conditions of the IVth climatic zone (40C and

75%RH).

Specific objectives

· Determination of the drug content

· Determination of the in vitro drug dissolution

· Evaluation of the impact of accelerated stability

testing (storage at 40°C, 75 % RH) on drug content and in vitro

dissolution.

According to this study an acceptable

formulation complies with the USP 24 specifications with the respect to the

dissolution and amount of active ingredients. A stable product is defined as a

product which shows no significant degradation or change in its physical and

chemical properties and remains within the labelled specifications.

II. Quantitative drug analysis and evaluation of the

influence of accelerated stability testing on the in vitro dissolution.

Immediate release solid dosage forms are routinely subjected

to tests such as content uniformity, weight, friability, hardness and

disintegration, tests mainly performed by manufacturers to assess

batch-to-batch uniformity. As the efficacy and safety of a dosage form is

dependent on the content of active ingredient, the test for drug content is

recommended in pharmacopoeia monographs. The test which is often most

associated with the assessment of in vivo performance is the in vitro

dissolution test, because even when a formulation contains the right amount of

drug it can fail to release the content at the site of absorption due to the

poor dissolution.

- Dissolution tests are used to assess the dissolution

properties of the drug itself in order to choose appropriate excipients for the

formulation.

- Dissolution tests are a very important tool to ensure

continuing product quality and performance after certain changes, such as

changes in the formulation, the manufacturing process, the site of manufacture,

and the scale-up of the manufacturing process (Guidance for industry, 1997).

- Clinical scientists rely on dissolution tests to establish

an in vitro/in vivo correlation between drug release from the dosage form and

drug absorption. The dissolution of an oral solid product can impact the rate

and the amount of drug available for absorption and hence influence the

therapeutic efficacy of the product. It is essential that the dissolution

characteristics remain unchanged throughout the product shelf life.

- Generally in developing countries, where technology and other

resources are limited to conduct an in vivo bioequivalence study, appropriate

dissolution studies, such as profile comparison between the local generic

product and the reference product under different test conditions may be used

to assure product quality (Shah, 1998).

Stability of a pharmaceutical product means the maintenance of

the quality defined in the specifications of the drug product up till the end

of the manufacturer's stated shelf life. The quality of the drug product is

determined by the content and purity of the active ingredient and by the

organoleptic, physiochemical and microbiological properties (Grimm, 1986).

Stability tests are a series of tests designed to obtain

information on the stability of pharmaceutical products, in order to define

their shelf life and utilisation period under specified packaging and storage.

Dissolution stability is an important tool to assess the quality of the

product. Is therefore both the legal and ethical responsibility of the

manufacturer to ensure that the product meets all the quality specifications

during the shelf life period as long as it is stored under the conditions

specified on the label.

For worldwide stability tests, the earth is divided into four

climatic zones into which individual countries are assigned. Rwanda can be

assigned to the climatic zone II (subtropical and Mediterranean climates,

storage conditions 25°C/60% RH) (Grimm, 1998). If imported drug

formulations have not been optimised for the corresponding climate zone, their

effectiveness may be compromised during transportation or/and storage.

Regarding the regulatory aspects, the WHO recommends an

accelerated stability test under zone IV climatic conditions (storage

conditions of 40 °C / 75 % RH) to be performed on all drugs intended for

the global market (Matthews, 1999).

II.1. Amoxicillin formulations

II.1.1 Material and equipment

Materials

· Amoxyphar 250 mg capsules ( Labophar,

Rwanda)

· Elymox 250 mg capsules (Elys chemical

industries, Kenya)

· Amoxysha 500 mg capsules (Dilam, Canada)

· Amoxicillin (Alpha Pharma, Belgium)

· Acetonitrile (Biosolve, The Netherlands)

· Monobasic potassium phosphate (Vel, Belgium)

All these chemicals and reagents were at least of analytical

grade.

Equipment

· Incubator: U-60 (Memmert, Analis, Namen,

Belgium)

· Column: Lichrospher 100 RP-C 18 e (5um), 250X4

mm

(Merck-Hitachi, Darmstadt,

Germany)

· Detector: L-7400 UV detector (Merck-Hitachi,

Darmstadt, Germany)

· Pump: L-7100 pump (Merck-Hitachi,

Darmstadt, Germany)

· Integrator: D-7000 integrator (Merck-Hitachi,

Darmstadt, Germany)

· Software Package `HPLC System Manager'

(Merck-Hitachi, Darmstadt,

Germany)

· Lambda 12 UV/VIS Spectrophotometer

(Perkin Elmer UV/VIS,

Perkin Elmer, Norwalk, USA)

· Dissolution equipment (VK 7000, Vankel

Technology, Cary, NC, USA)

II.1.2 Quantitative drug analysis

1.2.1 Methods

The amount of amoxicillin and the dissolution rate for each

formulation were determined by using the methods described in the USP 24

monograph for amoxicillin.

· Standard preparation

160 mg of amoxicillin was accurately weighed and dissolved in

about 80 ml of diluent. The resulting solution was diluted to 100.0 ml to give

a solution with an amoxicillin concentration of 1600 mg/l. 7.5ml from the above

solution were diluted to 10.0 ml with diluent to give a standard solution with

an amoxicillin concentration of 1200 mg/l.

· Sample preparation

The content of 10 capsules was removed as complete as possible

and accurately weighed. A portion equivalent to 240 mg of anhydrous amoxicillin

was dissolved in about 180 ml of diluent.The suspension was mixed, sonicated

and diluted to 200.0 ml, then filtered through a 0.2um cellulose acetate filter

(Sartorius, Goettingen, Germany). The filtrate was used as assay

preparation.

· Calibration curve

A calibration curve (peak area vs. amoxicillin concentration)

y = 29147 (298)x + 2709 (59) with a correlation coefficient (R2) of

0.9996 (0.0001) (n = 3) was constructed using standard solutions from 60 to 300

mg/l. The precision of the method was determined by calculating the relative

standard deviation (within a day and within three days)

of the peak area responses after repeated injections (n =3) of

an amoxicillin standard solution (120 mg/l).

· Diluent preparation

13.6 g of monobasic potassium phosphate

(KH2PO4) was dissolved in 2000 ml of distilled water, the

pH adjusted to 5.0 0.1 by using a 45% (w/w) aqueous solution of potassium

hydroxide.

· Mobile phase

The mobile phase consisted of a degassed mixture of diluent

and acetonitrile in a ratio of 94:6 (v/v).

· Chromatographic

conditions

Flow rate: 1.4 ml/min

Detection wavelength: 230 nm

Injection volume: 20ul

Temperature: Room temperature

Equal volumes of standard and assay preparations were

separately injected, the chromatograms were recorded, and the major peak

integrated. The quantity, in mg, of anhydrous amoxicillin in the portion of

capsules taken was calculated by the formula:

0.2 CP( ru/rs )

In which C is the concentration, in mg/ml, of amoxicillin in

the standard preparation, P is the stated amoxicillin content in ug/mg,

ru and rs are the amoxicillin peak responses obtained

from the assay and the standard preparation, respectively.

A part of the capsules was stored in a sealed box above a

saturated solution of sodium chloride (RH 75% 5 %). The sealed box was placed

in an incubator maintained at 40°C.

1.2.2 Results

The relative standard deviation (RSD) of the chromatographic

method was 0.24 % within a day and 1.36% within three days, which complies with

the USP 24 requirements (RSD should be less than 2%) and proving the precision

of the method.

The results of the drug content (Table 1.1) show that all

formulations complied with USP 24 specifications for amoxicillin content (90% -

120% of the labelled content).

Table 1.1: The amoxicillin content (expressed

as a percentage of the labelled amount) before and after 6 months of stability

testing at simulated tropical conditions.

Manufacturer

% of the labelled amount per capsule

0 months

6 months

Elys chemicals (Elymox) 102.4

100.8

Labophar (Amoxyphar) 103.7

101.6

Dilam (Amoxysha 500) 100.8

98.4

Containing 500 mg amoxicillin per capsule.

II.1.3 In vitro dissolution

1.3.1 Methods

· Preparation of dissolution

medium

Distilled water was used as dissolution medium.

· Calibration curve

Stock solution

30 mg of amoxicillin standard powder was accurately weighed

and dissolved into a required volume of dissolution medium to make a solution

having a concentration of 300mg/l, used as stock solution.

Standard solutions

5, 10, 15, 20, and 25 ml from the stock solution were

separately transferred to 25.0 ml volumetric flasks and diluted to volume using

dissolution medium. The resulting standard solutions had concentrations of 60,

120, 180, 240 and 300 mg/l. Absorbances of the above standard solutions were

spectrophotometrically measured at 272 nm.

A calibration curve (absorbance vs. amoxicillin concentration)

y = 0.003x + 0.0017 with a correlation coefficient (R2) of 0.9999

was constructed.

· Dissolution testing

Dissolution profiles were determined using the USP basket

method (Method 1) at a rotational speed of 100 rpm for capsules containing 250

mg, and using the USP paddle method (Method 2) at a rotational speed of 75 rpm

for capsules containing 500 mg.

Each of 6 capsules was placed inside a dissolution vessel

filled with 900 ml of dissolution medium maintained at 37 0.5°C. At

different time intervals (10, 20, 30, 40, 50 and 60 minutes) 5 ml of samples

were manually withdrawn, filtered, and analyzed spectrophotometrically at 272

nm for their amoxicillin concentration. Samples from 500 mg capsules were

diluted twice before analysis. The amount of the drug dissolved was calculated

by means of the above mentioned calibration curve.

1.3.2 Results

Table 1.2 shows the percentage dissolved within 60 minutes of

dissolution testing and Figure 1.1 the different dissolution profiles. Before

stability testing all drugs complied with the USP 24 dissolution requirements

(not less than 80% of the labelled amount should dissolve within 60 minutes).

The amount of drug released after 60 minutes of dissolution test was more than

90% for all formulations. The accelerated stability testing did not affect the

dissolution profiles; the percentage released remained within the USP 24 limits

for all formulations.

Table 1.2: Percentage amoxicillin dissolved within 60 minutes

of dissolution testing before and after 3 and 6 months of storage at 40°C

and 75% RH. USP requirements: more than 80 % released within 60 minutes.

Manufacturer

% of the labelled amount released

0 month 3 months 6 months

Elys chemicals (Elymox) 99.9

94.5 91.3

Labophar (Amoxyphar) 96.7

96.3 96.7

Dilam (Amoxysha 500) 104.2

102.9 97.7

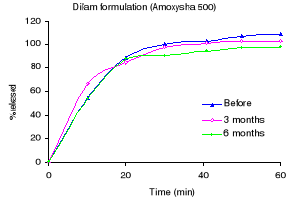

Figure 1.1: Dissolution profiles of amoxicillin formulations

before and after 3 and 6 months storage at 40°C and 75 % RH.

II.2 Acetylsalicylic acid formulations

II.2.1 Material and equipment

Material

· Aspirin 500 mg tablets (B.J. International, India)

· Minasprin 300 mg tablets (Girlloh Pharmacy, Surendra

Nagar, India)

· Saraprin 500 mg tablets (S&R pharmaceuticals,

Rwanda)

· Aspirin 500 mg tablets (Bayer, Greece)

· Acetonitrile (Biosolve, The Netherlands)

· Acetylsalicylic acid (Sigma - Aldrich chemie,

Germany)

· Salicylic acid (Ludeco-Belgium)

· Formic acid (Sigma - Aldrich chemie, Germany)

· 1-Heptanesulfonate sodium (Sigma - Aldrich chemie,

Germany)

· Glacial acetic acid (Vel, Belgium)

· Potassium dihydrogen phosphate (Vel, Belgium)

· Orthophosphoric acid (Vel, Belgium)

· Sodium acetate anhydrous (Vel, Belgium)

All chemicals and reagents were at least of analytical

grade.

Equipment

· Incubator: U-60 (Memmert, Analis, Namen,

Belgium)

· Column: Lichrospher 100 RP-C 18 e (5um), 250X4

mm

(Merck-Hitachi, Darmstadt,

Germany)

· Detector: L-7400 UV detector (Merck-Hitachi,

Darmstadt, Germany)

· Pump: L-7100 pump (Merck-Hitachi,

Darmstadt, Germany)

· Integrator: D-7000 integrator (Merck-Hitachi,

Darmstadt, Germany)

· Software Package `HPLC System Manager'

(Merck-Hitachi, Darmstadt,

Germany)

· Lambda 12 UV/VIS Spectrophotometer

(Perkin Elmer UV/VIS,

Perkin Elmer, Norwalk, USA)

· Dissolution equipment (VK 7000, Vankel

Technology, Cary, NC, USA)

II.2.2 Quantitative drug analysis

2.2.1 Methods

The amount of acetylsalicylic acid and salicylic acid and the

dissolution rate for each formulation was determined using the methods

described in USP 24.

· Mobile phase

1.36 g of potassium dihydrogen phosphate was weighed dissolved

in distilled water to make 1L of solution having a concentration of 0.01M.

0.67 ml of orthophosphoric acid (H3PO4 ,

M.M: 98, 1.71 kg/l, 85%) were transferred to a 1L flask and distilled water was

added to make a 0.01M solution. The above solutions were mixed in a ratio of

50:50 and the pH adjusted to 2.3 with orthophosphoric acid.

A mixture of the resulting solution, acetonitrile, and

methanol in the portion of 70:25:5 respectively was used as mobile phase.

· Standard solution salicylic acid

(SA)

30 mg of salicylic acid was accurately weighed and dissolved

in mobile phase to make 100 ml of solution. The resulting solution had a

salicylic acid concentration of 300 mg/l.

500ul of the above solution were diluted to 10 ml, to obtain a

standard solution with a salicylic acid concentration of 15 mg/l.

· Standard solution acetylsalicylic

acid (ASA)

100 mg of acetylsalicylic acid was accurately weighed and

dissolved to make a 100.0 ml solution, from which 5 ml was diluted twice to

obtain a standard solution having an acetylsalicylic acid

concentration of 500 mg/l.

· Sample preparation

From each formulation 10 tablets were weighed and powdered. An

accurately weighed portion of powder, equivalent to 100 mg of acetylsalicylic

acid was dissolved in 20 ml of mobile phase. The mixture was vigorously shaken

for about 10 minutes, and then filtered through a 0.2-um cellulose acetate

filter (Sartorius, Goettingen, Germany).

1.0 ml from the filtrate was diluted to 10.0 ml with diluting

solution. The final solution had a theoretical concentration of 500 mg/l

acetylsalicylic acid, and was used for the determination of the acetylsalicylic

acid and salicylic acid amount in the formulation analysed.

· Calibration curve

A calibration curve (peak area vs. acetylsalicylic

concentration) y = 12151 ( 44) x + 2378 (1115) with a correlation coefficient

(R2) of 0.9999 (0.0001) (n = 3) was constructed using standard

solution concentrations from 100 to 500 mg/l. And for salicylic acid a

calibration curve) y = 938 (28) x - 5015 (516) with a correlation coefficient

(R2) of 0.9999 (0.0001) (n = 3) was constructed using standard

solutions concentrations from 10 to 50 mg/l. The precision of the

acetylsalicylic acid and salicylic acid determination was determined by

calculating the relative standard deviation (RSD) of the peak area responses

after repeated injections (n =3) of a mixture of acetylsalicylic acid and

salicylic acid standard solution (500 : 50mg/l) a day and within three days.

The resolution factor (R) between acetylsalicylic and

salicylic acid was calculated as

R= 2 (t2 - t1 ) / (w1

+ w2)

With t1 and w1 being the retention time

and baseline width of the acetylsalicylic peak, t2 and w2

the respective values for salicylic acid.

· Chromatographic

conditions

Flow rate : 1.2 ml/min

Detection wavelength : 280 nm

Injection volume : 20ul

Temperature : Room

temperature

· Procedure

Equal volumes of the acetylsalicylic acid standard and assay

preparations were separately injected, the chromatograms were recorded and the

major peaks integrated. The quantity Q, in mg, of aspirin in the portion of

tablets taken was calculated by the formula:

Q = 200 C (ru/rs)

In which C is the concentration, in mg/ml, of acetylsalicylic

acid in the standard preparation, ru and rs are the

aspirin peak responses obtained from the assay and the standard preparation,

respectively.

The quantity, in mg, of salicylic acid in the portion of

tablets taken was calculated by the formula:

2000 (C/Q) (ru/rs)

In which C is the concentration, in mg/ml, of salicylic acid

in the standard preparation, Q the quantity, in mg, of acetylsalicylic acid in

the portion of tablets as determined above, ru and rs are

the salicylic acid peak responses obtained from the assay and the standard

preparation, respectively.

· Stability testing

A part of the tablets was stored in a sealed box containing a

saturated solution of sodium chloride (RH 75% 5 %). The box was placed in an

incubator maintained at 40°C 2°C. After 3 and 6 months, tablets were

withdrawn from the incubator and evaluated for dissolution rate and their

content of active ingredient.

2.2.2 Results

The RSD was 0.25 % within a day and 1.78% within three days,

which complies with the USP 24 requirements (RSD should be less than 2%). The

resolution between acetylsalicylic acid and salicylic acid peaks was 1.75,

which means that those two compounds were well separated. The results of the

drug content (Table 2.1) show that the B.J. International formulation failed to

comply with the USP 24 specifications for acetylsalicylic acid content (90% -

110%). All formulations were compliant with the USP 24 specifications for

salicylic acid limits (<0.3%) (Table 2.2). Upon 6 months of storage at

40°C and 75 % RH, only the Bayer formulation did not show a significant

change. The B.J. International formulation was badly affected as almost 50% of

the tablet was transformed into the powder. As a consequence the salicylic acid

content increased and the acetylsalicylic acid content decreased

dramatically.

Table 2.1 The acetylsalicylic acid content (expressed as a

percentage of the labelled amount) before and after 6 months of stability

testing at simulated tropical conditions.

Manufacturer % of the

labelled amount per tablet

0 months

6 months

Bayer 99.4

94.3

B.J. International 87.0

59.0

Girlloh (Minasprin) 99.4

80.3

S&R (Saraprin) 91.7

-

Table 2.2 The salicylic acid content (expressed as a

percentage of the acetylsalicylic acid labelled amount) before and after 6

months of stability testing at simulated tropical conditions.

Manufacturer

% of salicylic acid

0 months 6 months

Bayer 0.00

0.24

BJ international 0.00

0.61

Girlloh (Minasprin) 0.01

0.24

S&R (Saraprin)

0.02 -

Containing 300 mg of acetylsalicylic acid per tablet.

Not analyzed for stability testing.

II.2.3 In vitro dissolution

2.3.1 Methods

· Preparation of dissolution

medium

The dissolution medium consisted of 0.05M acetate buffer

prepared as follows: 9 g of anhydrous sodium acetate was dissolved in 800 ml

distilled water, 8.3 ml of glacial acetic acid was added. The resulting

solution was diluted to 5.0L.

· Calibration curve

Stock solution

35 mg of acetylsalicylic acid reference powder was accurately

weighed and transferred to a 100.0 ml volumetric flask. 1 ml of methanol was

added, then about 50 ml of dissolution medium. The mixture was sonicated for

about 2 min. The solution was diluted to 100.0 ml using the dissolution medium

to obtain a stock solution with a concentration of 350 mg of acetylsalicylic

acid / l.

Standard solutions

3, 4, 5, 7 and 9 ml were separately diluted to 10.0 ml using

the dissolution medium; the resulting standard solutions had concentrations of

105, 140, 175, 245 and 315 mg/l acetylsalicylic acid, respectively. Absorbances

of those solutions were spectrophotometrically measured at 265nm. A calibration

curve (absorbance vs. acetylsalicylic acid concentration) y = 0.0027x + 0.0031

with a correlation coefficient (R2) of 0.9998 was constructed.

Dissolution testing

Dissolution profiles were determined using the USP basket

method (Method 1). Each of 6 tablets was added to a basket fixed to a stirring

shaft, placed inside a dissolution vessel (filled with 900 ml of dissolution

medium maintained at 37°C 0.5°C) and rotated at a speed of 50 rpm. At

different time intervals (5, 10, 15, 20, 25 and 30 min) 5ml filtered samples

were manually withdrawn, diluted twice with dissolution medium and

spectrophotometrically analysed at 265 nm. Concentrations were calculated from

the above mentioned calibration curve.

2.3.2 Results

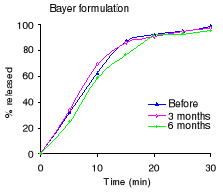

The dissolution profiles for each formulation before and after

3 and 6 months of accelerated stability testing are shown in Figure 2.1 and the

percent drug released after 30 minutes in Table 2.3. Before stability testing

the S&R formulation did not disintegrate, while others complied with the

USP 24 requirements (not less than 80% dissolved within 30 minutes). After six

months of stability testing, only the Bayer formulation remained compliant with

the USP 24 requirements. The percentage released for Minasprin formulation

decreased, however it remained compliant with the USP 24 requirements. The

release rate of the B.J International formulation decreased dramatically.

Table 2.3 Percentage of acetylsalicylic acid dissolved within

30 minutes of dissolution testing before and after 3 and 6 months of storage at

40°C and 75% RH. USP requirements: more than 80 % released within 30

minutes.

Manufacturer % of the

labelled amount per tablet

0 months

3 months 6 months

Bayer 99.0

97.2 95.6

BJ international 84.7

71.8 34.3

Girlloh (Minasprin) 97.2

80.5 76.5

S&R (Saraprin) 5.1

- -

Not analyzed for 3 and 6 months.

Figure 2.1 Dissolution profiles of acetylsalicylic acid before

and after 3 and 6 months of storage at 40°C and 75 % RH:

II.3 Sulfamethoxazole / Trimethoprim (Cotrimoxazole)

formulations

II.3.1 Material and equipment

Material

· Batrimox 480 mg tablets (Sulfamethoxazole 400 mg /

Trimethoprim 80 mg)

(S&R Pharmaceuticals, Rwanda)

· Unitrim 480 mg tablets(Sulfamethoxazole 400 mg /

Trimethoprim 80 mg)

(Elys chemicals industries, Kenya)

· Bactiphar 480 mg tablets (Sulfamethoxazole 400 mg /

Trimethoprim 80 mg) (Labophar, Rwanda)

· Sulfamethoxazole (Alpha pharma, Belgium)

· Trimethoprim (Alpha pharma, Belgium)

· Hydrochloric acid 37% (Merck/Eurolab, Darmstadt,

Germany)

· Acetonitrile HPLC grade (Biosolve, The Netherlands)

· Glacial acetic acid 100% (Merck/Eurolab, Darmstadt,

Germany)

· Triethylamine (Sigma chemicals, St Louis, USA)

Equipment

· Incubator: U-60 (Memmert, Analis, Namen,

Belgium)

· Column: Lichrospher 100 RP-C 18 e (5um), 250X4

mm

(Merck-Hitachi, Darmstadt,

Germany)

· Detector: L-7400 UV detector (Merck-Hitachi,

Darmstadt, Germany)

· Pump: L-7100 pump (Merck-Hitachi,

Darmstadt, Germany)

· Integrator: D-7000 integrator (Merck-Hitachi,

Darmstadt, Germany)

· Software Package `HPLC System Manager'

(Merck-Hitachi, Darmstadt,

Germany)

· Lambda 12 UV/VIS Spectrophotometer

(Perkin Elmer UV/VIS,

Perkin Elmer, Norwalk, USA)

· Dissolution equipment (VK 7000, Vankel Technology,

Cary, NC, USA)

II.3.2 Quantitative drug analysis

3.2.1 Methods

The amount of sulfamethoxazole and trimethoprim and the

dissolution rate of both drug for each formulation were determined using the

methods described in the USP 24.

· Mobile phase

A mixture of 650 ml distilled water, 250 ml acetonitrile, and

1 ml triethylamine was homogenized and allowed to equilibrate at room

temperature. The pH of the above mixture was adjusted to 5.9 0.1 using diluted

glacial acetic acid (10%). The resulting solution was diluted to 1.0 L to

obtain the mobile phase.

· Standard solution

Separately, 160 mg of sulfamethoxazole and 32 mg of

trimethoprim were accurately weighed and dissolved in methanol to give a 100.0

ml solution. The above solution had a concentration of 1600 mg/l and 320 mg/l

of sulfamethoxazole and trimethoprim, respectively. 5.0 ml from the above

solution was diluted to 50.0 ml to obtain standard solution with concentration

of 160 mg/l and 32 mg/l of those two compounds, respectively.

· Sample preparation

From each formulation 10 tablets were weighed and finely

powdered. An accurately weighed portion of powder equivalent to 160 mg of

sulfamethoxazole was diluted with mobile phase to give 100.0 ml of suspension,

sonicated for about 5 min and filtered through a 0.2-um cellulose acetate

filter (Sartorius, Goettingen, Germany). 5.0 ml from the filtrate were diluted

to 50.0ml and used as assay preparation.

· Calibration curve

A calibration curve (peak area vs. concentration) y = 64590

(122) x + 43448 (351) with a correlation coefficient (R2) of 0.9995

(0.0001) (n = 5) was constructed using standard solutions with sulfamethoxazole

concentrations from 16 to 160 mg/l. For trimethoprim a calibration curve y =

31476 (1265) x + 2088 ( 509) with a correlation coefficient (R2) of

0.9979 (0.0025) (n = 5) was constructed using standard solutions with

trimethoprim concentrations from 3.2 to 32 mg/l. The precision of the method

was determined by calculating the relative standard deviation (within a day and

within three days) of the peak area responses after repeated injections (n = 5)

of a standard solution (160 mg/l sulfamethoxazole and 32 mg/l trimethoprim).

The resolution factor (R) between sulfamethoxazole and

trimethoprim was calculated from their respective peaks:

R= 2 ( t1 - t2 ) / (w1

+ w2)

With t1 and w1 being the retention time

and baseline width of the sulfamethoxazole peak, t2 and

w2, the respective values for trimethoprim.

· Chromatographic

conditions

Flow rate : 0.8 ml/min

Detection wavelength : 254 nm

Injection volume : 20ul

Temperature : Room

temperature

· Procedure

Equal volumes of standard and assay preparations were

separately injected, the chromatograms were recorded and the major peaks

integrated. The drug quantities, Q, (in mg of sulfamethoxazole and trimethoprim

in the portion of tablets taken) were calculated by the formula:

Q=1000 C (ru/rs)

Whereby C is the concentration, in mg/ml, of sulfamethoxazole

and trimethoprim in the standard preparation, ru and rs

are the analyte corresponding peak responses obtained from the assay and the

standard preparation, respectively.

· Stability testing

A part of the tablets was stored in a sealed box containing a

saturated solution of sodium chloride (RH 75 5 %). This box was placed in an

incubator maintained at 40 2°C. After 3 and 6 months, tablets were

withdrawn from the incubator and evaluated for dissolution rate and their

content in active ingredient.

3.2.2 Results

The RSD was 0.47 and 0.24 % within a day and 1.51 and 1.29 %

within three days for sulfamethoxazole and trimethoprim, respectively; which

complies with the USP 24 requirements (RSD should be less than 2%). The

resolution factor R between sulfamethoxazole and trimethoprim was 8.02, which

means that they were well separated. As shown in Table 3.1, the S&R

formulation (Batrimox) failed to comply with USP 24 requirements in terms of

drug content for sulfamethoxazole (93 - 107 % of the labelled amount of

sulfamethoxazole and trimethorim).

There was no impact of stability testing on the drug content

for the Elys formulation (Unitrim), while the drug content of both

sulfamethoxazole and trimethoprim for the Labophar formulation (Bactiphar)

decreased.

Table 3.1 The

sulfamethoxazole and trimethoprim content (expressed as a percentage

of the labelled amount) before and after 6 months of stability testing at

simulated tropical conditions.

Manufacturer

% of the labelled amount per tablet

0 months 6 months

Sulfamethoxazole

Elys Chemicals (Unitrim) 97.1

94.6

Labophar (Bactiphar) 97.2

92.8

S&R pharmaceuticals (Batrimox)* 91.6

-

Trimethoprim

Elys Chemicals (Unitrim) 99.6

97.0

Labophar (Bactiphar) 98.1

84.8

S&R pharmaceuticals (Batrimox)* 97.4

-

* Not analyzed for stability testing because it failed the

dissolution test for both two

compounds immediately after purchase.

II.3.3 In vitro dissolution

3.3.1 Methods

· Preparation of dissolution

medium

98.64 ml of 37 % hydrochloric acid was diluted to 10.0 L with

distilled water. The resulting 0.1 N solution was used as dissolution

medium.

· Calibration curves of

sulfamethoxazole and trimethoprim

Based on the HPLC method, the calibration curves mentioned in

quantitative drug analysis were used for calculation of the amount of drug

released. The same mobile phase, the same standard solutions and the same

concentrations were used.

· Dissolution testing

Dissolution profiles were determined using the USP paddle

method (Method 2). Each of 6 tablets was placed inside a dissolution vessel

filled with 900 ml of dissolution medium maintained at 370.5°C stirred by

paddles rotating at 75 rpm. At 10, 20, 30, 40, 50 and 60 minutes 5 ml samples

were withdrawn, filtered, diluted 5 times and analysed for their contents of

sulfamethoxazole and trimethoprim by UV at 254 nm after chromatographic

separation.

Procedure

20 ul of each of the collected samples was injected onto the

HPLC system and the corresponding peak areas were recorded. The content of each

sample was calculated using the calibration curve.

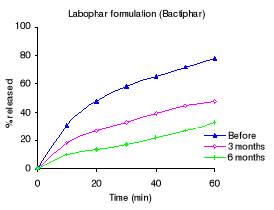

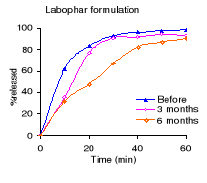

3.3.2 Results

Table 3.2 shows the percentage drug dissolved and Figures 3.1

to 3.3 the dissolution profiles of different formulations analyzed. For

sulfamethoxazole the Elys formulation (Unitrim) complied with the USP 24

requirements (not less than 70% of sulfamethoxazole and trimethoprim labelled

amount should dissolve within 60 min), however the drug percentage released

decreased after 6 months of storage at 40°C/ 75% RH. Labophar formulation

(Bactiphar) released 45% of the drug, the S&R formulation (Batrimox)

released only 15%. Those last two formulations did not disintegrate completely

within 60 minutes. For trimethoprim, 90% of the labelled amount of Unitrim and

77.5% of Bactiphar were released within 60 min, which complies with USP 24,

while Batrimox failed (only 35.4 % was released).

Table 3.2 Percentage of sulfamethoxazole and

trimethoprim dissolved within 60 minutes of dissolution testing before, after 3

and 6 months of storage at 40°C and 75% RH. USP requirements: more than 70

% released within 60 minutes.

Manufacturer

% of the labelled amount per tablet

0 months 3 months 6 months

Sulfamethoxazole

Elys Chemicals (Unitrim) 98.0

94.2 77.0

Labophar (Bactiphar) 45.0

38.5 25.8

S&R pharmaceuticals (Batrimox) 15.0

- -

Trimethoprim

Elys Chemicals (Unitrim) 95.1

92.2 90.2

Labophar (Bactiphar) 77.6

47.4 32.5

S&R pharmaceuticals (Batrimox) 35.4

- -

Figure 3.1 In vitro dissolution profiles of sulfamethoxazole

and trimethoprim before stability testing

Figure 3.2 Dissolution profiles of sulfamethoxazole

formulations before and after 3 and 6 months storage at 40°C and 75 %

RH.

Figure 3.3 Dissolution profiles of trimethoprim formulations

before and after 3 and 6 months of storage at 40°C and 75 % RH.

II.4 Metronidazole formulations

II.4.1 Material and equipment

Material

· Elogyl 200mg tablets (Elys Chemicals Industries,

Kenya)

· Metronidazole 250mg tablets (Holden Medica, The

Netherlands)

· Metronidazole 250mg tablets (Labophar, Rwanda)

· Metronidazole (Alpha pharma, Belgium)

· Methanol (Biosolve, The Netherlands)

· Hydrochloric acid (Sigma Aldrich Chemie, Germany)

All chemicals and reagents were at least of analytical

grade.

Equipment

· Incubator: U-60 (Memmert, Analis, Namen,

Belgium)

· Column: Lichrospher 100 RP-C 18 e (5um), 250X4

mm

(Merck-Hitachi, Darmstadt,

Germany)

· Detector: L-7400 UV detector (Merck-Hitachi,

Darmstadt, Germany)

· Pump: L-7100 pump (Merck-Hitachi,

Darmstadt, Germany)

· Integrator: D-7000 integrator (Merck-Hitachi,

Darmstadt, Germany)

· Software Package `HPLC System Manager'

(Merck-Hitachi, Darmstadt,

Germany)

· Lambda 12 UV/VIS Spectrophotometer

(Perkin Elmer UV/VIS,

Perkin Elmer, Norwalk, USA)

· Dissolution equipment (VK 7000, Vankel Technology,

Cary, NC, USA)

II.4.2. Quantitative drug analysis

4.2.1 Methods

The amount of metronidazole and the dissolution rate for each

formulation were determined using the methods described in USP 24.

· Mobile phase

A degassed mixture of methanol and distilled water (20:80) was

used as mobile phase.

· Standard preparation

An accurately weighed quantity (50 mg) of metronidazole

standard was dissolved in mobile phase to obtain a 100.0 ml solution having a

known concentration of 0.5 mg/ml, which was used as standard preparation.

· Assay preparation

From each formulation 10 whole tablets were transferred to a

suitable sized volumetric flask, which when diluted with methanol yielded a

solution having a concentration of 10 mg/ml. In case of Elys formulation

(Elogyl) a 200.0 ml flask was used, while for the others 250.0 ml flasks were

used. Methanol was added and the mixture shaken by mechanical means until the

tablets were disintegrated. Methanol was added to volume. The mixture was

allowed to stand until the insoluble material had settled. 5 ml of the clear

supernate liquid was pipeted, diluted to 100.0 ml using mobile phase, mixed and

filtered through a 0.2 um cellulose acetate filter (Sartorius, Goettingen,

Germany). The resulting filtrate was used as assay preparation.

· Chromatographic

conditions

Flow rate: 1ml/min

Detection wavelength: 254 nm

Injection volume: 20ul

Temperature: Room temperature

· Calibration curve

A calibration curve (peak area vs. concentration) y = 16582622

(133565) x + 73066 (9932) with a correlation coefficient (R2) of

0.9997 (0.0001) (n = 3) was constructed using standard solutions from 50 to 500

mg/l.

The precision of the method was determined by calculating the

relative standard deviation (within a day and within three days) of the peak

area responses after repeated injections (n =3) of a metronidazole standard

solution (500 mg/l).

· Procedure

Equal volumes of standard and assay preparations were

separately injected, the chromatograms were recorded and the major peaks

integrated. The drug quantity, Q, (in mg of metronidazole in the portion of

tablets taken) was calculated by the formula:

Q = 10(L/D) C (ru/rs)

Whereby L is the labelled amount, in mg, of metronidazole in

each tablet, D is the concentration (mg/ml) of metronidazole in the assay

preparation, C is the concentration (mg/ml) of the standard preparation,

ru and rs are the metronidazole peak responses obtained

from the assay preparation and the standard preparation, respectively.

· Stability testing

A part of the tablets was stored in a sealed box containing a

saturated solution of sodium chloride (RH 75% 5 %). The box was placed in an

incubator maintained at 40°C 2°C. After 3 and 6 months, tablets were

withdrawn from the incubator and evaluated for dissolution rate and their

content of active ingredient.

4.2.2 Results

The RSD was 0.37 % within a day and 0.46% within three days,

which complies with the USP 24 requirements (RSD should be less than 2%).

The results of the drug content (Table 4.1) show that all

formulations complied with the USP 24 specifications for metronidazole content:

90% - 110% of the labelled amount.

Table 4.1: The metronidazole content

(expressed as percentage of the labelled amount) before and after 6 months of

storage at 40°C and 75 % RH.

Manufacturer % of

the labelled amount per tablet

0

months 6 months

Elys chemicals 98.2

93.5

Labophar 98.6

97.2

Holden Medica 91.7

90.3

II.4.3 In vitro dissolution

4.3.1 Methods

· Preparation of dissolution

medium

98.64 ml of 37% hydrochloric acid was diluted to 10.0L with

distilled water. The resulting 0.1N hydrochloric acid solution was used as

dissolution medium.

· Calibration curve

Stock solution

40 mg of metronidazole was accurately weighed, dissolved in

dissolution medium and sonicated for about 5 min to give a 25 ml solution

having a concentration of 1600 mg/l.

5 ml from this solution was diluted to 50.0 ml with

dissolution medium to give a stock solution with a concentration of 160

mg/l.

Standard solutions

0.5, 0.75, 1, 2 and 3 ml of the stock solution were separately

diluted with dissolution medium to 10.0 ml. The standard solutions obtained had

concentrations of 8, 12, 16, 32 and 48 mg/l, respectively.

A calibration curve (absorbance vs. concentration) y =

0.0355x + 0.0114 with a correlation coefficient (R2) of 0.9998 was

constructed.

· Dissolution testing

Dissolution profiles were determined using the USP basket

method (Method 1). Each of 6 tablets was added to a basket connected to a

stirring shaft which was placed inside a dissolution vessel filled with 900ml

of dissolution medium maintained at 370.5°C. The rotation speed of the

basket was 100 rpm. At 10, 20, 30, 40, 50 and 60 minutes, 5ml samples were

withdrawn, filtered, diluted 20 times and analysed spectrophotometrically at

278nm.

4.2.2 Results

Table 4.2 shows the percentage dissolved within 60 minutes of

dissolution testing and Figure 4.1 the different dissolution profiles. Before

stability testing all drugs complied with the USP 24 dissolution requirements

(not less than 80% of the labelled amount should dissolve within 60 minutes).

The amount of drug released after 60 minutes of dissolution test was more than

90% for all formulations. The Holden Medica formulation did not withstand the

storage at high temperature and high relative humidity: the percentage released

being outside the specifications after 6 months.

Table 4.2: Percentage of metronidazole dissolved within 60

minutes of dissolution testing before and after 3 and 6 months of storage at

40°C and 75% RH. USP requirements: more than 80 % released within 60

minutes.

Manufacturer % of the

labelled amount released

0 months

3 months 6 months

Elys chemicals (Elogyl) 97.8

99.8 88.7

Labophar 98.2

92.6 90.1

Holden medica 95.3

87.8 66.9

Figure 4.1: Dissolution profiles of metronidazole formulations

before and after 3 and 6 months of storage at 40°C and 75 % RH.

II.5 Paracetamol formulations

II.5.1 Material and equipment

Material

· Cetamol 500 mg tablets (Regal pharmaceuticals,

Kenya)

· Panadol 500 mg tablets (SmithKline Beecham, Kenya)

· Saramol 500 mg tablets (S&R Pharmaceuticals,

Rwanda)

· Paracetamol (Ludeco, Belgium)

· Potassium dihydrogen phosphate (Vel, Belgium)

· Sodium hydroxide (Acros Organics, Belgium)

· Methanol-HPLC quality (Biosolve B, The Netherlands)

All chemicals and reagents were at least of analytical

grade.

Equipment

· Incubator: U-60 (Memmert, Analis, Namen,

Belgium)

· Column: Lichrospher 100 RP-C 18 e (5um), 250X4

mm

(Merck-Hitachi, Darmstadt,

Germany)

· Detector: L-7400 UV detector (Merck-Hitachi,

Darmstadt, Germany)

· Pump: L-7100 pump (Merck-Hitachi,

Darmstadt, Germany)

· Integrator: D-7000 integrator (Merck-Hitachi,

Darmstadt, Germany)

· Software Package `HPLC System Manager'

(Merck-Hitachi, Darmstadt,

Germany)

· Lambda 12 UV/VIS Spectrophotometer

(Perkin Elmer UV/VIS,

Perkin Elmer, Norwalk, USA)

· Dissolution equipment (VK 7000, Vankel Technology,

Cary, NC, USA)

II.5.2 Quantitative drug analysis

5.2.1 Methods

The amount of paracetamol and the dissolution rate for each

formulation was determined using the method described in USP 24.

· Mobile phase

A degassed mixture of distilled water and methanol (75:25) was

used as mobile phase.

· Standard preparation

An accurately weighed quantity of paracetamol (100 mg) was

dissolved in mobile phase to make a 100 ml solution having a concentration of 1

mg/ml. From that solution 200 ul was diluted to 20.0 ml, and a resulting

solution (0.01 mg/ml) was used as standard solution.

· Sample preparation

From each formulation, 10 tablets were weighed and finely

powdered. An accurately weighed portion of powder, equivalent to 100 mg of

paracetamol was diluted with mobile phase to make 100 ml of mixture, which was

filtered through a 0.2um cellulose acetate filter (Sartorius, Goettingen,

Germany). From the filtrate 1 ml was diluted to 100.0 ml with mobile phase.

· Chromatographic

conditions

Flow rate : 1.5 ml/min

Detection wavelength : 243 nm

Injection volume : 20 ul

Temperature : Room

temperature

· Calibration curve

A calibration curve (peak area vs. concentration) y = 94199

(1687) x - 16441 (2852) with a correlation coefficient (R2) of

0.9998 (0.0002) (n = 3) was constructed using standard solutions from 4 to 40

mg/l.

The precision of the method was determined by calculating the

relative standard deviation (within a day and within three days) of the peak

area responses after repeated injections (n =3) of a paracetamol standard

solution (20 mg/l).

· Procedure

Equal volumes of standard and assay preparations were

separately injected, the chromatograms were recorded, and the major peak

integrated.

The drug quantity, Q, (in mg of paracetamol in the portion of

tablets taken) were calculated by the formula:

Q = 10.000C( ru/rs)

Whereby C is the concentration (mg/l) of the standard

preparation, ru and rs are the paracetamol peak responses

obtained from the assay preparation and the standard preparation,

respectively.

· Stability testing

A part of the tablets was stored in a sealed box above a

saturated solution of sodium chloride (RH 75 5 %). This box was placed in an

incubator maintained at 40 2°C. After 3 and 6 months, tablets were

withdrawn from the incubator and evaluated for dissolution rate and their

content in active ingredient.

5.2.2 Results

The RSD was 0.78 % within a day and 1.56% within three days,

which complies with the USP 24 requirements (RSD should be less than 2%).

The results of the drug content (Table 5.1) show that the

S&R formulation did not comply with the USP 24 specifications for

paracetamol content (90% - 110% of the labelled amount) after 6 months of

storage under simulated tropical conditions (40°C and 75 % RH).

Table 5.1: The paracetamol content (expressed

as percentage of the labelled amount) before and after 6 months of storage at

40°C and 75 % RH.

Manufacturer

% of the labelled amount per tablet

0 months 6 months

Regal Pharmaceuticals (Cetamol) 95.6

92.5

Smith Kline Beecham (Panadol) 95.0

93.8

S&R Pharmaceuticals (Saramol) 90.8

87.7

II.5.3 In vitro dissolution

5.3.1 Methods

· Preparation of dissolution

medium

68 g of potassium dihydrogen phosphate was diluted to 10.0 L

with distilled water. The pH was adjusted to 5.8 0.05 using a 0.2 N solution

of sodium hydroxide.

· Calibration curve

Stock solution

200 mg of accurately weighed paracetamol was dissolved in

mobile phase to obtain 100.0 ml. 10 ml from this solution were diluted to 100.0

ml. The resulting solution had a concentration of 200 mg/l. 20 ml of this

solution was diluted to 100.0 ml to give a stock solution with a concentration

of 40 mg/l.

Standard solutions

1, 2, 5, 8 and 10 ml of the stock solution were separately

diluted to 10.0 ml using the dissolution medium to obtain standard solutions

having concentrations of 4, 8, 20, 32 and 40 mg/l, respectively.

A calibration curve (absorbance vs. concentration) y = 0.0633x

+ 0.0294 with a correlation coefficient (R2) of 0.9999 was

constructed.

· Dissolution testing

Dissolution profiles were determined using the USP paddle

method (Method 2). Each of 6 tablets was placed inside a dissolution vessel

filled with 900 ml of dissolution medium maintained at 37 0.5°C and

rotated at a speed of 50 rpm.

At different time intervals (5, 10, 15, 20, 25 and 30 min) 5 ml

filtered samples were manually withdrawn, diluted with dissolution medium

(1:40) and spectrophotometrically analyzed at 243 nm. From the absorbance of

each sample, the drug concentration was calculated by means of the calibration

curve.

5.3.2 Results

Table 5.2 shows the percentage dissolved within 30 minutes of

dissolution testing and Figure 5.1 the different dissolution profiles. Before

stability testing all drugs complied with the USP 24 dissolution requirements

(not less than 80% of the labelled amount should dissolve within 30 minutes).

The amount of drug released after 10 minutes of dissolution test was more than

80% for the Cetamol and Panadol formulations. The Saramol formulation

disintegrated into larger particles compared to the others two formulations.

The accelerated stability testing did not affect the Cetamol and Panadol drug

percentage released. The amount of drug released from Saramol formulation

decreased, however it remained within USP 24 tolerance limits for dissolution

testing.

Table 5.2: Percentage of paracetamol dissolved within 30

minutes of dissolution testing before and after 3 and 6 months of storage at

40°C and 75% RH. USP requirements: more than 80 % released within 60

minutes.

Manufacturer

% of the labelled amount per tablet

0

months 3 months 6 months

Regal Pharmaceuticals (Cetamol) 95.6

94.6 90.4

Smith Kline Beecham (Panadol) 95.0

94.9 93.9

S&R Pharmaceuticals (Saramol) 90.8

90.1 84.3

Figure 5.1: Dissolution profiles of paracetamol formulations

before and after 3 and 6 months of storage at 40°C and 75 % RH.

II.6 Quinine formulations

II.6.1 Material and equipment

Material

· Quinine sulfate 300 mg tablets (Pharmakina, Dem. Rep.

of Congo)

· Quinine sulfate sugar-coated 300 mg tablets (Elys

Chemicals, Kenya)

· Quinine (base) 300 mg tablets (Labophar, Rwanda)

· Quinine sulfate dihydrate 99 % (Acros Organics,

Belgium)

· Methane sulfonic acid (Acros Organics, Belgium)

· Diethylamine (Vel, Belgium)

All chemicals and reagents were at least of analytical

grade.

Equipment

· Incubator: U-60 (Memmert, Analis, Namen,

Belgium)

· Column: Lichrospher 100 RP-C 18 e (5um), 250X4

mm

(Merck-Hitachi, Darmstadt,

Germany)

· Detector: L-7400 UV detector (Merck-Hitachi,

Darmstadt, Germany)

· Pump: L-7100 pump (Merck-Hitachi,

Darmstadt, Germany)

· Integrator: D-7000 integrator (Merck-Hitachi,

Darmstadt, Germany)

· Software Package `HPLC System Manager'

(Merck-Hitachi, Darmstadt,

Germany)

· Lambda 12 UV/VIS Spectrophotometer

(Perkin Elmer UV/VIS,

Perkin Elmer, Norwalk, USA)

· Dissolution equipment (VK 7000, Vankel Technology,

Cary, NC, USA)

II.6.2 Quantitative drug analysis

6.2.1 Methods

The amount of quinine and the dissolution rate for each

formulation was determined using the method described in USP 24 monogrphs.

· Mobile phase

The mobile phase consisted of a filtered and degassed mixture

of water, acetonitrile, methane sulfonic acid, and diethylamine solution

(860:100:20:20). The pH was adjusted to 2.6 with a diethylamine solution .

The methanesulfonic acid solution was prepared as follows: 35

ml of methanesulfonic acid was added to 20 ml of glacial acetic acid and the

mixture was diluted to 500.0 ml with distilled water.

Diethylamine solution: 10 ml of diethylamine was diluted to

100.0 ml with distilled water.

· Standard preparation

20 mg of quinine sulfate, accurately weighed, was transferred

to a 100 ml volumetric flask, dissolved and diluted to volume with mobile

phase. The resulting solution was used as standard preparation.

· Assay preparation

From each formulation 10 tablets were weighed and finely

powdered.

An accurately weighed portion of powder, equivalent to about

160 mg of quinine sulfate, was dissolved in about 80 ml of methanol and

mechanically shaken for about 30 minutes, then diluted to 100 ml. The mixture

was filtered through a 0.2 um cellulose acetate filter (Sartorius, Goettingen,

Germany). The first 10 ml were discarded. 3 ml of the filtrate was diluted to

25 ml with mobile phase to obtain an assay preparation with concentration of

192 mg/l.

· Chromatographic

conditions

Flow rate : 1 ml/min

Detection wavelength : 235 nm

Injection volume : 20 ul

Temperature : Room

temperature

· Calibration curve

A calibration curve (peak area vs. concentration) y = 38643219

(5716) x + 78532 (2321) with a correlation coefficient (R2) of

0.9997 (0.0000) (n = 3) was constructed using standard solutions from 0.1 to

1.0 g/l.

The precision of the method was determined by calculating the

relative standard deviation (within a day and within three days) of the peak

area responses after repeated injections (n =3) of a quinine sulfate standard

solution (200 mg/l).

· Procedure

Equal volumes of standard and assay preparations were

separately injected, the chromatograms were recorded and the major peaks

integrated. The drug quantity, Q, (in mg of the sum of quinine sulfate and

dihydroquinine sulfate in the portion of tablets taken) was calculated by the

formula:

Q = (2500/3)C (r b, u +r d, u)/( r b,

s +r d, s)

In which C is the concentration, in mg/ml, of quinine sulfate

in the standard preparation, r b, u and r b, s are the

peak responses of quinine obtained from the assay preparation and the standard

preparation, respectively, rd, u and r d, s are the peak

responses of dihydroquinine obtained from the assay and the standard

preparation, respectively.

· Stability testing

A part of the tablets was stored in a sealed box above a

saturated solution of sodium chloride (RH 75 5 %). This box was placed in an

incubator maintained at 40 2°C. After 3 and 6 months, tablets were

withdrawn from the incubator and evaluated for dissolution rate and their

content of active ingredient.

6.2.2 Results

The RSD was 0.65 % within a day and 1.67% within three days,

which complies with the USP 24 requirements (RSD should be less than 2%).

The results of the drug content (Table 6.1) show that all

formulations complied with the USP 24 specifications for quinine sulfate

content: 90% - 110% of the labelled amount of quinine sulfate. Whereas the

content of the Labophar tablets was just above the lower limit of the required

interval before stability testing, it failed after six months of storage at

40° C and 75% RH.

Table 6.1: The quinine content (expressed as

percentage of the labelled amount) before and after 6 months of storage at

40°C and 75 % RH.

Manufacturer

% of the labelled amount per tablet

0 months 6 months

Elys Chemicals

105.0 98.1

Labophar

90.2 86.4

Pharmakina

97.0 94.6

II.6.3. In vitro dissolution

6.3.1 Methods

· Preparation of dissolution

medium

98.64 ml of 37% hydrochloric acid was diluted to 10.0 L with

distilled water. The resulting 0.1N hydrochloric acid solution was used as

dissolution medium.

· Calibration curve

Stock solution

40 mg of quinine sulfate was accurately weighed and

transferred to a 25 ml volumetric flask and dissolved to volume using the

dissolution medium. 1 ml from the above solution was diluted to 100.0 ml to

give a stock solution with a concentration of 16 mg/l.

Standard solutions

4, 8, 10, 16 and 20 ml from the stock solution were separately

diluted to 20.0 ml to give standard solutions with concentrations of 3.2, 6.4,

8.0, 12.8 and 16.0 mg/l.

A calibration curve (absorbance vs. concentration) y = 0.0925x

+ 0.0053 with a correlation coefficient (R2) of 0.9999 was

constructed.

· Dissolution testing

Dissolution profiles were determined using the USP basket

method (Method 1). Each of 6 tablets was added to a basket connected to a

stirring shaft which was placed inside a dissolution vessel filled with 900ml

of dissolution medium maintained at 37 0.5°C. The rotation speed was 100

rpm. At 10, 20, 30, 35, 40 and 45 min 5 ml samples were withdrawn, filtered,

diluted (1:40) and spectrophotometrically analyzed at 248 nm.

6.3.2 Results

Table 6.2 shows the percentage dissolved within 45 minutes of

dissolution testing and Figure 6.1 the different dissolution profiles. Before

stability testing all drugs complied with the USP 24 dissolution requirements

(not less than 75% of the labelled amount should dissolve within 45 minutes).

The amount of drug released after 45 minutes of dissolution test was more than

80% for all formulations. The Elys formulation was affected by stability test

conditions, the drug percentage released decreased from 103.2% to 41.8% after 6

months. For the others, the drug released remained within USP 24 tolerance

limits for dissolution testing.

Table 6.2: Percentage of quinine dissolved within 30 minutes

of dissolution testing before and after 3 and 6 months of storage at 40°C

and 75% RH. USP requirements: more than 75 % released within 45 minutes.

Manufacturer

% of the labelled amount per tablet

0 months 3months 6 months

Elys Chemicals 103.2

69.6 41.8

Labophar

88.2 85.6 85.0

Pharmakina

96.1 94.0 92.7

Figure 6.1 Quinine dissolution profiles before, after 3 and 6

months of storage at 40°C and 75 % RH.

II.7 Sulfadoxine & Pyrimethamine formulations

II.7.1 Material and equipment

Material

· Orodar® 525 mg tablets (sulfadoxine

500mg / pyrimethamine 25mg)

(Elys chemicals Industries, Kenya)

· Sulfadoxine 500mg / pyrimethamine 25mg (Labophar,

Rwanda)

· Sulfadoxine (Indis, Belgium)

· Pyrimethamine (Sigma-Aldrich Chemie, Germany)

· Potassium dihydrogen phosphate (Vel, Belgium)

· Phenacetin (Sigma-Alidrich Chemie, Germany)

· Acetonitrile (Biosolve, The Netherlands)

· Glacial acetic acid (Merck Eurolab)

· Perchloric acid (UCB, Belgium)

All chemicals and reagents were at least of analytical

grade.

Equipment

· Incubator: U-60 (Memmert, Analis, Namen,

Belgium)

· Column: Lichrospher 100 RP-C 18 e (5um), 250X4

mm

(Merck-Hitachi, Darmstadt,

Germany)

· Detector: L-7400 UV detector (Merck-Hitachi,

Darmstadt, Germany)

· Pump: L-7100 pump (Merck-Hitachi,

Darmstadt, Germany)

· Integrator: D-7000 integrator (Merck-Hitachi,

Darmstadt, Germany)

· Software Package `HPLC System Manager'(Merck-Hitachi,

Darmstadt)

· Lambda 12 UV/VIS Spectrophotometer

(Perkin Elmer UV/VIS,

Perkin Elmer, Norwalk, USA)

· Dissolution equipment (VK 7000, Vankel Technology,

Cary, NC, USA)

II.7.2 Quantitative drug analysis

7.2.1 Methods

The amount of sulfadoxine and pyrimethamine and the

dissolution rate for each formulation was determined using the methods

described in USP 24.

· Mobile phase

A mixture of glacial acetic acid and water was made at the

ratio of (1:50). 1200 ml from the above solution was mixed with 800ml of

acetonitrile, and then 8ml of perchloric acid was added. The homogenized

mixture was used as mobile phase.

· Internal standard:

120 mg of phenacetin was dissolved and diluted to 100.0 ml. 10

ml of that solution was diluted to 100.0 ml to obtain an internal solution

having a concentration of 120 mg/l.

· Stock solution

550mg of sulfadoxine and 27 mg of pyrimethamine were

separately weighed and dissolved in 35 ml of acetonitrile, mobile phase was

added to 100.0 ml. 10 ml from the above solutions was diluted to 100.0 ml to

obtain stock solution with concentrations of 550 mg/l for sulfadoxine and 27

mg/l for pyrimethamine, respectively.

Standard solutions

1, 2, 3, 5 and 6 ml from the stock solution were separately

transferred into different flasks, 1 ml of internal standard was added, after

which the solutions were diluted to 10.0 ml to obtain standard solutions having

concentrations of 55, 110, 165, 275 and 330 mg/l for sulfadoxine. The

pyrimethamine concentrations were 2.7, 5.4, 8.1, 13.5 and 16.2 mg/l.The

internal concentration was always 12 mg/l of phenacetin.

· Sample preparation

From each formulation 10 tablets were weighed and powdered. An

accurately weighed portion of powder, equivalent to 550 mg of sulfadoxine and

27 mg of pyrimethamine, was dissolved in 35 ml acetonitrile. The mixture was

sonicated for about 25 minutes, diluted with mobile phase to 100.0 ml. The

mixture was then filtered through a 0.2-um cellulose acetate filter (Sartorius,

Goettingen, Germany).

From the filtrate 5 ml was transferred to a 100.0 ml flask, 1

ml of phenacetin solution (internal standard) was added and the volume was

adjusted with mobile phase to make the assay preparation.

· Calibration curve

For sulfadoxine, a calibration curve (peak area of the

sulfadoxine/phenacetin ratios vs. concentration) y = 0.0427 (0.0000) x + 0.2276

(0.0133) with a correlation coefficient (R2) of 0.9999 (0.0000) (n =

5) was constructed using standard solutions from 55 to 330 mg sulfadoxine /

l.

For pyrimethamine, y = 0.0433 (0.0000) x - 0.0197 (0.0007)

with a correlation coefficient (R2) of 0.9999 (0.0001) (n = 5) was

constructed using standard solutions from 2.7 to 24.3 mg pyrimethamine / l.

The precision of the method was determined by calculating the

relative standard deviation (RSD) of the peak area responses after repeated

injections (n =5) of a sulfadoxine/pyrimethamine standard solution (275 and

13.5 mg/l, respectively) a day and within three days.

The resolution factors between sulfadoxine and phenacetin(R)

and between phenacetin and pyrimethamine (R') were calculated from their

respective peaks:

R= 2 (t2 - t1) / (w1 +

w2)

With t1 and w1 being the retention time

and baseline width of the sulfadoxine peak, t2 and w2,

the respective values of phenacetin.

R' = 2 (t3 - t2 ) /

(w2+ w3 )

With t2 and w2 being the retention time

and baseline width of the phenacetin peak, t3 and w3 ,

the respective values pyrimethamine.

· Chromatographic

conditions

Flow rate : 1.4 ml/min

Detection wavelength : 254 nm

Injection volume : 20 ul

Temperature : Room

temperature

· Procedure

Equal volumes of standard and assay preparations were

separately injected, the chromatograms were recorded and the major peaks

integrated. The drug quantity, Q, (in mg, of sulfadoxine in the portion of

tablets taken was calculated by the following formula:

Q = 12.5 C (r u / r

s)

In which C is the concentration, in mg/l, of sulfadoxine in

the standard preparation, ru and rs the peak responses

obtained from the assay preparation and the standard preparation, respectively.

The drug quantity, Q, (in mg, of pyrimethamine in the portion

of tablets taken was calculated by the following formula:

Q = 0.2 C' (r' u / r'

s)

In which C is the concentration, in mg/l, of pyrimethamine in

the standard preparation, r'u and r's the peak responses

obtained form the assay preparation and the standard preparation,

respectively.

· Stability testing

A part of the tablets was stored in a sealed box containing a

saturated solution of sodium chloride (RH 75% 5 %). The box was placed in an

incubator maintained at 40°C 2°C. After 3 and 6 months, tablets were

withdrawn from the incubator and evaluated for dissolution rate and their

content in active ingredient.

7.2.2 Results

The RSD was 0.68 % within a day and 1.57 % within three days,

which complies with the USP 24 requirements (RSD should be less than 2.5 %).

The resolution between sulfadoxine and phenacetin and between pyrimethamine and

phenacetin was 2.3 and 1.9, respectively, which means that those three

compounds were well separated.

The sulfadoxine and pyrimethamine contents for each

formulation (Table 7.1) were within the USP 24 requirements (90 - 110 % of the

labelled amount of both sulfadoxine and pyrimethamine). The stability test

conditions did not affect the formulations because the drug content did not

show significant change.

Table 7.1 The sulfadoxine and pyrimethamine

content (expressed as percentage of the labelled amount) before and after 6

months of storage at 40°C and 75 % RH.

Manufacturer %

of the labelled amount per tablet

0

months 6 months

Sulfadoxine

Elys Chemicals (Orodar) 105.3

103.4

Labophar 100.0

98.9

Pyrimethamine

Elys Chemicals (Orodar) 105.5

101.5

Labophar 90.9

90.3

II.7.3 In vitro dissolution

7.3.1 Methods

· Preparation of dissolution

medium

68 g of monobasic potassium phosphate was accurately weighed

and dissolved in about 9 L of distilled water. The pH was adjusted to 6.8 using

a 2 N sodium hydroxide solution and distilled water was added to 10.0 L.

· Calibration curves of sulfadoxine and

Pyrimethamine

Using the HPLC method, the calibration curves mentioned in

quantitative drug analysis were used for calculation of the amount of drug

released. The same mobile phase, the same standard solutions and the same

concentrations were used.

· Dissolution testing

Dissolution profiles were determined using the USP paddle

method (Method 2). Each of 6 tablets was placed inside a dissolution vessel

filled with 900ml of dissolution medium maintained at 370.5°C and stirred

by paddles rotated at 75 rpm. At 5, 10, 15, 20, 25 and 30 min 5 ml samples were

withdrawn, filtered, diluted 3 times and analyzed for their contents of

sulfadoxine and pyrimethamine by UV at 254 nm after chromatographic

separation.

Procedure

20 ul of each of the collected samples was injected onto the

HPLC system and corresponding peak areas were recorded.

The content of each sample was calculated based on the

calibration curves.

7.3.2 Results

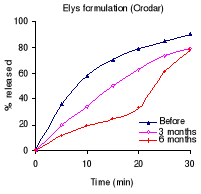

Table 7.2 shows the percentage drug dissolved and Figures 7.1

and 7.2 the dissolution profiles of the different formulations analyzed.

Before stability testing, all formulations complied with the

USP 24 requirements for sulfadoxine: not less than 60% of the sulfadoxine and

pyrimethamine labelled amount should dissolve within 30 minutes. For