PREPARATION OF POLYSTYRENE WITH HIGHER Tg BASED ON

TRIPLE HYDROGEN BOND INTERACTION

MBULU AGALIA

MATERIALS SCIENCE

\u26085ÈÕ \u26399ÆÚ:

\u20108þ \u9675ð \u9675ð \u20061¾Å

\u24180Äê \u19968Ò» \u26376ÔÂ

\u20108þÊ® \u26085ÈÕ

Contents

Abstract...............................................................

......... .........2

Abstract in Chinese ...

................................................................4

Chapter 1 Introduction................ ...................

......5

1.1 Glass transition

temperature.............................................................5

1.2

Styrene and Maleimide

copolymer....................................................14

1.3 Melamine and chemistry

.............................................................23

1.4 Diaminopyridine

molecule..............................................................26

1.5 the thesis

work...........................................................................27

Chapter 2 Experimentation

Section.............................................31

2.1

Materials.................................................................................31

2.2

Instruments..............................................................................31

2.3 Synthesis of random copolymers of styrene and

maleimide......................32

2.4 Synthesis of Blends of Styrene/Maleimide copolymer and

melamine...........32

2.5 Synthesis of Blends of the copolymer and

2,6-diaminopyridine.................33

Chapter 3 Results and

discussion................................................34

3.1 Characterization of copolymer of styrene and

maleimide..........................34

3.2 Copolymerization of styrene and

maleimide........................................33

3.3 Blends of the styrene/maleimide copolymers and

melamine............................38

3.4 Blends of the copolymer and

2,6-diaminopyridine..................................43

Chapter 4

Conclusion.................................................................46

Reference...................................................................................47

PREPARATION OF POLYSTYRENE WITH HIGHER Tg BASED ON

HYDROGEN BOND INTERACTION

ABSTRACT

Polystyrene is one of a common polymer. But its glass

transition temperature (Tg) is only 100oC which leads to limit its

applications. In the thesis, improvement of its Tg was done via increase of its

chain interactions to restrict the chain flexibility.

Styrene was copolymerized with maleimide, imide of which act

as a hydrogen-bond interaction site in the copolymer, by free radical

polymerization method in DMSO solution at different temperature, and

different ratio of styrene to maleimide, and different reaction time, using

different amount of AIBN as an initiator. To make the imide distribute

randomly in the chains, maleimide was dropped slowly during the

polymerization. Melamine and diaminopyridine were selected to be as interaction

molecule because they can form the triple hydrogen bond with imide in the

copolymer. Addition of melamine or diaminopyridine into the copolymer results

in a dramatic increase of Tg. Polystyrene with imide molar concentration of

5.05% has Tg of 122oC in the presence of melamine, 22 oC

higher than polystyrene, which will extend application of polystyrene. At high

ratio of melamine to imide, two Tgs are observed, one is higher than

122oC but another much lower. The existence of two Tg is due to the

fact that free melamine is acting as plasticizer.

Diaminopyridine also increase Tg of polystyrene, but not

effectively than melamine owing to lack of crosslinking. In this case, the

blend of Diaminopyridine with polystyrene containing imide looks like a

copolymer of styrene with a big monomer, complex of maleimide and

Diaminopyridine.

The secondary interaction characteristics between melamine or

Diaminopyridine with polystyrene containing imide is confirmed by their blends

readily soluble in DMSO and in CH2Cl2.

Chapter 1 Introduction

1.1 Glass transition temperature

Many plastics lose their strength at relatively low

temperature. Continuous-service-temperature comparison of plastics reveals that

most common plastics can endure temperature more than 150oC when

under low or no stress. Glass transition temperature or Glass point

(Tg) is the point at which polymers act as glass or become viscous

liquids. That's a very important factor for polymers to evaluate their

processing and application performances.

The Glass transition is a reversible change that occurs when a

resin polymer is heated to a certain temperature (Tg), resulting in

a sudden change or transition from rigid polymer to a flexible, rubbery

material or a viscous liquid. When the polymer is cooled below this

temperature, it becomes hard and brittle, like glass. Certainly there are a few

polymers used above their Glass transition temperatures, however majority of

polymers are used below. Popular hard plastics like polystyrene

(Tg=100oC) is used below their glass transition

temperatures; that is its glassy state. Their Glass transition temperatures are

well above room temperature, both at around 100oC.

Rubbers elastomers like polyisoprene and polyisobutylene are

used above their Glass transition temperatures; that is in the rubbery sate

where they are soft and flexible.

The glass transition differs from the melting transition by

the fact that the former is a transition which happens to amorphous polymers

and the latter is a transition which occurs in crystalline polymers. But even

crystalline polymers will have some amorphous portions; this portion usually

makes up 40-70% of the polymer sample. This is why the same sample of a polymer

can have both a Glass transition temperature and a melting temperature. But

only the amorphous portion undergoes the glass transition and only the

crystalline portion undergoes melting. This change in mobility with temperature

happens because heat is really a form of kinetic energy.

The exact temperature at which the polymer chain undergoes

this big change in mobility depends on the structure of the polymer. A polymer

chain that can move around fairly easily will have a very low Tg, while one

that doesn't move so well will have a high one. The more easily a polymer can

move the less heat it takes for the chains to commence wiggling and break out

of the rigid glassy state and into the soft rubbery state. A given polymer

sample does not have a unique value of Tg because the glass phase

is not at equilibrium.

1.1.1 Factors governing Tg

The height of the glass-rubber transition temperature is, in

the first instance, governed by the competition between thermal motion and the

attraction forces between the chains.

The thermal motion is depend on the freedom of the chain to

undergo changes in conformation .When this freedom is higher, the chain is

subjected to a stronger thermal motion than a chain which, e.g. as result of

hindrance in rotation, is more rigid, the chain stiffness plays an important

role.

The primary criteria are:

-chain flexibility

-chain interactions

1.1.2 Chain flexibility

Higher chain stiffness results from a smaller number of

possible chain conformations; this can be caused by:

-greater stiffness of the main chain

-bigger side groups

-cross links

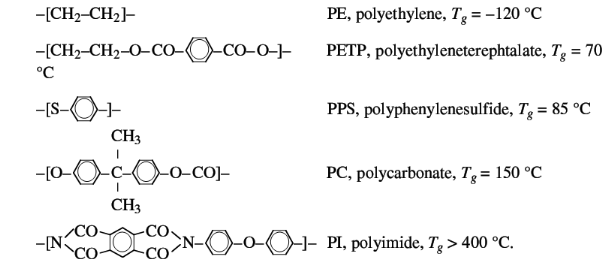

Some examples of the chain stiffness differences in the main

chain are:

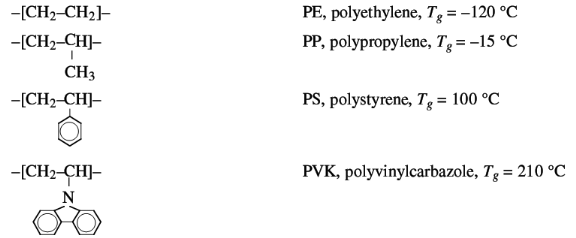

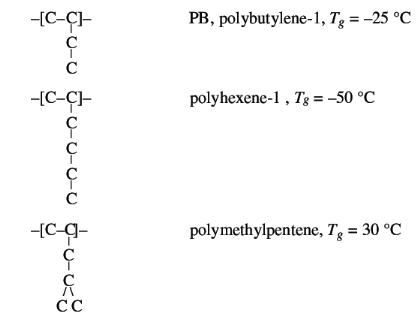

Some examples of the effect of side groups on the chain

flexibility are:

The increasing size of the side group effects a decrease of

chain flexibility and an increase of Tg.

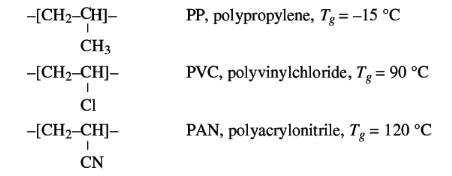

1.1.3 Chain interactions

The strongest of molecular interaction are the dipole forces.

Their effect on Tg is illustrated by the series PP, PVC and PAN, in which the

chain mobility hardly varies because the side groups are of about equal size,

but in which, in the order of sequence mentioned, the dipole interaction

increase.

Interaction can be decreased by increasing the distance

between the chains, for instance with long side chains, which lower Tg. This

effect appears to be greater than the increase of chain stiffness, as shown in

the examples below:

Approximate glass transition temperatures and melting point

of a few polymers are shown below:

Table1-1 glass transition temperatures of

common polymers

|

Polymer

|

LDPE

|

HDPE

|

PP

|

PVC

|

PS

|

PAN

|

PTFE

|

PMMA

|

PMMA

|

|

Tm(oC)

|

110

|

130

|

175

|

180

|

175

|

>200

|

330

|

180

|

30

|

|

Tg(oC)

|

-110

|

-110

|

-20

|

80

|

100

|

95

|

-110

|

105

|

-70

|

1.1.4 Intermolecular interaction

There are three types of intermolecular forces:

-Van Der Waals forces

-Dipole forces

-Hydrogen bond interactions

Although all such forces arise from the same fundamental

source i.e., interaction of negatively charged electrons and positively charged

nucleus yet they differ in magnitude, effective range and mode of operation.

Usually they are much smaller than the forces responsible for chemical

bonding.

1.1.5 Van Der Waals interactions

These interactions arise due to transfer polarization of

neutral molecules and are also known as London forces. Usually neutral

molecules have balanced number of negative electrons and positive charge on the

nucleus. Yet since electrons are in motion, the centre of density of negative

charge may not coincide with the centre of density of positive charge

continuously. A molecular thus acquires an electric dipole and can exert an

attraction for other similar molecules. Such interaction is known as van Der

Waals interaction.

A polarized molecule may induce the electric dipole in a

neutral molecule. However such polarized molecule continually reverts back to

neutral state and dipole is only transient. The greater the number of electrons

in a molecule and farther their distance from nucleus, the greater will be the

case of polarization and consently stronger Van Der Waals forces. These forces

vary inversely with the seventh power of the distance between molecules.

V.F. á 1/d7

Where V.F. is Van Der Waals forces and d is distance

separating the molecules. They are effective only over short intermolecular

distances.

1.1.6 Dipole-Dipole Interactions

Unequal sharing of electrons in covalent bonds results in

bonds dipoles and their magnitudes are indicated by the bond moments. As may be

expected the bond dipoles in different molecules attract each other resulting

in dipole-dipole interaction. These forces (D.F,) are governed by the

expression: D.F. á 1/d4

Where d is the distance between molecules, thus these forces

also are effectives only over short distances but have larger range than Van

Der Waals forces.

1.1.7 Hydrogen Bonds

It has been observed that when a hydrogen atom in a compound

is bonded to a highly electronegative atoms such as N, O, F, then marked

differences are observed in its usual properties like boiling point, solubility

etc. For example the boiling point of organic compounds usually increases with

increase in molecular weight but, though ethyl alcohol

C2H5OH (b.p.78.2o) and dimethyl ether

CH3-O-CH3 (b.p. -24.9 o) have the same

molecular weight, yet there is large difference in their boiling points.

The chemical properties of these compounds also differ as

compared to similar compounds not having hydrogen attached to N, O, F.

It is argued that when hydrogen is attached to such

electronegative atoms the bonding electrons are drawn strongly towards the

electronegative atom creating a dipole in the molecule. The hydrogen atom

therefore, acquires a small positive charge and becomes extraordinarily capable

of attracting a negatively charged atom of a molecule. This attraction results

in association of such molecules though the H-atom known as Hydrogen

Bond. This is represented by a dotted line. It has much less strength

than covalent bond and is essentially the result of electrostatic interactions,

delocalization effects and dispersion effects.

Hydrogen bonds are attractive interactions between a

positively charged hydrogen atom bonded to an electronegative element (the

donor: ), and a negatively charged atom with a lone pair of electrons (the

acceptor:

), and a negatively charged atom with a lone pair of electrons (the

acceptor: )

)

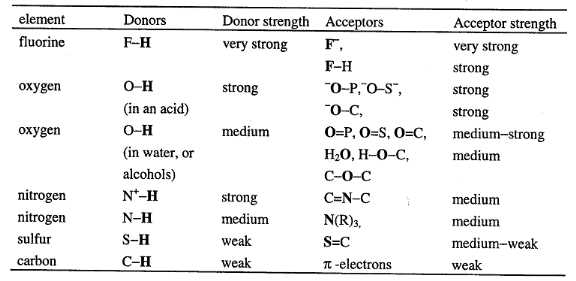

Table1-2 Functional group that can form

hydrogen bonds, arranged by element

The strongest hydrogen bonding is formed between a strong

donor (like F-H and O-H in acid) and a strong acceptor.

The type of H-bonding resulting in association of two or more

molecules of the same or different compound is known as Intermolecular hydrogen

bonding. Intermolecular association trough hydrogen bond results in unusually

high boiling points of the liquids. Thus, the high boiling points of water,

alcohols, amines and acids as compared to monomeric molecules of comparable

molecular weight may be explained on the basis of H-bonding.

Intermolecular Hydrogen bonding is the formation of H-bonging

within the molecule itself. Ethylacetoacetate, salicylaldehyde and

o-nitrophenol are example of this type.

1.2 Styrene and Maleimide

copolymer

Polystyrene is one of a common polymer. It is

very easy to produce and proceed, so very cheap, and has majority of properties

for usage in common life. However, its glass transition temperature (Tg) is

only 100 degree Celsius, which leads to limit its applications.

Polymers with high glass transition temperature are attractive

for industrial polymer science because of their strong economic rewards that

may arise from their potential application [1]. As mentioned above,

two factors governs Tg of polymers, chain flexibility and chain interaction.

Copolymerization is a best way to change both of them. In the case of

copolymers, the final value of a given property; e.g. the melting point or the

glass transition temperature does depend on both of monomer structures and the

composition of them, also the others[2]. The existing methods used

to improve Tg of Polystyrene are the copolymerization and control of its

configuration. Incorporation of a few of another stiff monomer shows less

improvement in Tg of polystyrene, because the Tg is a function of content of

stiff monomer. More content of stiff monomer makes Tg of styrene copolymer

higher, meanwhile many good properties, for instance, stiffness, transparent,

and processing property, will be lost. Isotactic polystyrene has very high

Tg(above 220oC). However, it is difficult to process and,

furthermore, it is gotten by much more complicated coordination polymerization

route, not by the easy free radical polymerization.

Styrene molecule or derivates are chemically modified by free

radical polymerization to obtain new products with various potential

applications and properties [3]. Copolymerization of maleimides with

styrene provides the possibility of synthesizing higher and thermally stable

polymers. In addition to that the processability of maleimide polymer can also

be enhanced by the incorporation of more flexible units within the polymer

backbone [1].

Styrene-Maleimide copolymer (SMA) have been found to have

versatile applications in many industries ranging from aerospace to the

microelectronics field [2]. During the past several years many

reports and researches in the free radical copolymerization of styrene with

maleimide have emerged[2-5].

1.2.1 General description

When a polymer is made by linking only one type of small

molecule, or monomer, together, it is called a homopolymer. When two different

types of monomers are joined in the same polymer chain, the polymer is called a

copolymer. Two monomers A and B can be made into a copolymer in many different

ways.

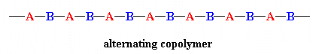

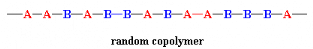

When the two monomers are arranged in an alternating fashion, the

polymer is called an alternating copolymer:

In a random copolymer, the two monomers may follow in any

order:

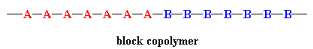

In a block copolymer, all of one type of monomer are grouped

together and all of the other are grouped together. A block copolymer can be

thought of as two homopolymers joined together at the ends:

When chains of a polymer made of monomer B are grafted on to a

polymer chain of monomer A we have a graft copolymer:

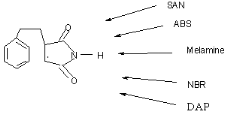

Styrene, also known as vinyl benzene is an

organic compound

with the

chemical formula

C6H5CH=CH2. Under normal conditions, this

aromatic

hydrocarbon is an oily

liquid. It evaporates easily

and has a sweet smell, although high concentrations confer a less pleasant

odor. Styrene is the precursor to

polystyrene, an

important synthetic material. Styrene Monomer is the raw material for

polystyrene and EPS, accounting for approximately two thirds of total styrene

monomer production. The remaining styrene monomer is used as a feedstock in the

production of SAN, ABS and the unsaturated polyester resins, SBR and polymer

latex. Major downstream styrene markets (polystyrene and ABS) are under

pressure as a result of oversupply and interpolymer competition, although

rationalization of older, smaller styrenics units should help balance out the

market.

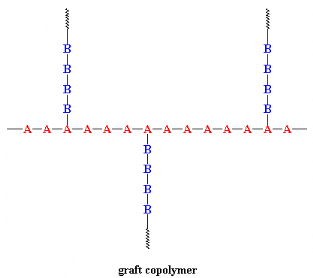

Maleimide is the

chemical compound

with the

formula

H2C2(CO)2NH. This unsaturated

imide is an important building

block in

organic synthesis.

The name is a contraction of

maleic acid and

imide, the -C(O)NHC(O)-

functional

group.

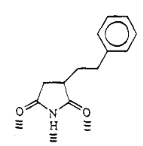

Fig1 Molecule of

Maleimide

Maleimide and its derivatives are prepared from

maleic anhydride by

treatment with

amines followed by

dehydration. A special feature of the reactivity of maleimides is their

susceptibility to additions across the double bond either by

Michael additions

or via

Diels-Alder

reactions.

A Copolymer is a polymer chain made up of two monomers units,

say A and B. When produced by copolymerization, the copolymer chain will

comprise a distribution of sequence lengths (S)which will depend upon the

monomer feed ratio [A]/[B] and the reactivity ratio (rA and

rB)which reflect the inherent tendencies of a radical to react with

its own monomer relative to the co-monomer.

Therefore, because of the feed ratio, the polymerization of

two or more monomers will result either to random copolymers, alternating

copolymer and block copolymers [6,7].

If a feed ratio of  is taken, then the reactivity ratios will indicate the inherent tendency

of a system to produce particular sequence length distributions and hence the

characteristic average sequence lengths. As an example, for a perfectly

alternating copolymer, rA=rB=0 and the monomers alternate

along the chain. Alternatively, for a completely random copolymer

rA=rB=1 and SA=SB=2

is taken, then the reactivity ratios will indicate the inherent tendency

of a system to produce particular sequence length distributions and hence the

characteristic average sequence lengths. As an example, for a perfectly

alternating copolymer, rA=rB=0 and the monomers alternate

along the chain. Alternatively, for a completely random copolymer

rA=rB=1 and SA=SB=2

One of the most common and useful reaction for making polymers

is free radical polymerization.

It is used to make polymers from vinyl monomers, that is, from

small molecules containing carbon-carbon double bonds. Polymers made by free

radical polymerization include

polystyrene,

poly (methyl methacrylate),

poly (vinyl acetate) and branched

polyethylene.

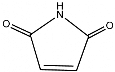

Copolymerization of maleimide with styrene monomers results in

a polymerization mechanism occurring via a charge-transfer complex or via the

penultimate model, but it is obvious that polymerization of an electron rich

monomer (styrene) with an electron poor monomer (maleimide) leads to a,

predominantly, alternating copolymer [8,9].

Fig 1-1 charge transfer complex during

the polymerization of styrene-maleimide copolymer

Fig 1-2

Styrene-Maleimide Copolymers

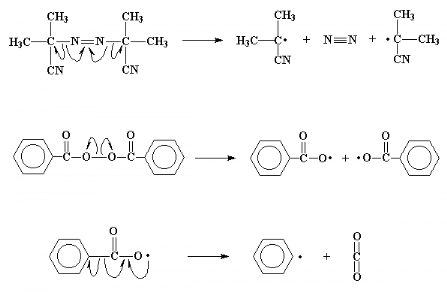

1.2.2 The initiator of Styrene-Maleimide copolymer

The whole process starts off with a molecule called an

initiator. This is a molecule like benzoyl peroxide or

2,2'-azo-bis-isobutyrylnitrile (AIBN).

What is special about these molecules is that they have an

uncanny ability to fall apart, in a rather unusual way. When they split, the

pair of electrons in the bond which is broken will separate. This is unusual as

electrons like to be in pairs whenever possible. When this split happens, we're

left with two fragments, called initiator fragments, of the original

molecule, each of which has one unpaired electron. Molecules like this, with

unpaired electrons are called free radicals.

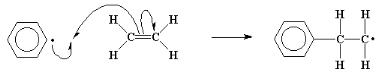

The carbon-carbon double bond in a vinyl monomer, like

ethylene, has a pair of electrons which is very easily attacked by the free

radical. The unpaired electron, when it comes near the pair of electrons, can't

help but swipe one of them to pair with itself. This new pair of electrons

forms a new chemical bond between the initiator fragment and one of the double

bond carbons of the monomer molecule. This electron, having nowhere else to go,

associates itself with the carbon atom which is not bonded to the initiator

fragment. You can see that this will lead us back where we started, as we now

have a new free radical when this unpaired electron comes to roost on that

carbon atom. This whole process, the breakdown of the initiator molecule to

form radicals, followed by the radical's reaction with a monomer molecule is

called the initiation step of the polymerization.

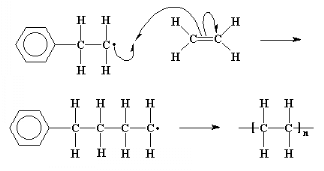

This process, the adding of more and more monomer molecules to

the growing chains, is called propagation.

Because we keep remaking the radical, we can keep adding more and

more ethylene molecules, and build a long chain of them. Self-perpetuating

reactions like this one are called chain reactions.

Coupling is one of two main types of termination

reaction. Termination is the third and final step of a chain-growth

polymerization.

1.3 Melamine molecule and chemistry

As we known, the physical properties of polymers are

significantly altered upon addition of low molecular weight compounds, e.g. the

addition of plastizers, which increase chain mobility, and enhance the

processability of polymeric materials[4]. However, a low molecular

weight compounds is easy to distribute in polymers and have a strong

interaction with polymers in some cases. It's known that the used of secondary

interaction(such as hydrogen bond, ion-ion, dipole-dipole or Van Der Waals

forces ) is also a well-accepted strategy to enhance miscibility of immiscible

polymers, and miscible polymers mixture based on hydrogen

bonding[5]. Most significantly, secondary interaction for the

self-assembly of macromolecules has been investigated more recently in detail

for liquid crystallinity, rotaxanes, catenanes and amphiphilic structures

[5]. Recently, Lehn et al. introduced the concept of using

well-defined secondary interactions based on hydrogen bonding in the synthesis

of liquid crystalline polymer, in which the repeating units are linked by

triple-hydrogen bonding instead of by covalent bonding [6].

Ronald F.M. Lange et al. have studied the interaction between

the alternating copolymer of styrene/maleimide with unsubstituted melamine .

They observed that addition of melamine results in a dramatic decrease of

Tg up to melamine concentration of 20%(w/w) at which the

Tg remains constant at around 215 oC [5,7].

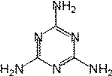

1.3.1 Structure of Melamine

Melamine is an organic base with the chemical formula

C3

H6

N6, with the

IUPAC name

1,3,5-triazine-2,4,6-triamine. It is only slightly soluble in water. Melamine

is a

trimer of

cyanamide. Like

cyanamide, it is 66%

nitrogen (by mass) and

provides

fire retardant

properties to resin formulas by releasing nitrogen when burned or charred.

Fig 1-3 1,3,5-Triazine-2,4,6-triamine

1.3.2 Chemistry of Melamine

It is well-known that melamine forms a 1;1 crystalline complex

[5,7,12]with cyanuric acid. The structure of this complex is proposed to be an

infinite two dimensional lattice as is showing in the figure 5

Fig 1-4 infinite two dimensional lattices,

proposed for the 1:1 complex of melamine and cyanuric acid.

This 1:1 melamine-cyanuric acid lattice has been a source of

inspiration in the development of supramolecular chemistry and the theory of

secondary interaction [7,12].

Various model studies (e.g. complexation of unsubstituted

melamine with a low molecular weight imide as well as with various imides

containing polymers) have been performed to mimic this triple hydrogen bond

formation [12].

However, few attempts have been made to mimic this triple

hydrogen bond formation using high molecular polymeric materials. In order to

mimic this triple hydrogen bond formation only alternating copolymers of SMA

have been used in the synthesis of blend between SMA with either melamine or

2.4-diaminotriazine[12]

1.4 2,6-diaminopyridine molecule

2,6-diaminopyridine is analogous melamine. It can also form

the triple hydrogen bond with SMA.

Fig 1-5 Potential precursors of the triple

hydrogen bonded Styrene Maleimide couple

Fig 1-6 2,6-Diaminopyridine

PYRIDINE is a heterocyclic aromatic tertiary amine characterized

by a six-membered ring structure composed of five carbon atoms and nitrogen

which replace one carbon-hydrogen unit in the benzene ring

(C5H5N). The simplest member of the pyridine family is

pyridine itself. It is colorless, flammable, toxic liquid with a unpleasant

odor, miscible with water and with most organic solvents, boils at 115

oC. Its aqueous solution is slightly alkaline. Its conjugate acid is

called pyridinium cation, C5H5NH+, used as a

oxidation agent for organic synthesis. Pyridine is a base with chemical

properties similar to tertiary amines. Nitrogen in the ring system has an

equatorial lone pair of electrons that does not participate in the aromatic

pi-bond. Its aqueous solution is slightly alkaline. It is incompatible and

reactive with strong oxidizers and strong acids, and reacts violently with

chlorosulfonic acid, maleic anhydride, oleum, perchromates, b-propiolactone,

formamide, chromium trioxide, and sulfuric acid. Liquid pyridine easily

evaporates into the air. If it is released to the air, it may take several

months to years until it breaks down into other compounds. Usually, pyridine is

derived from coal tar or synthesized from other chemicals, mainly acetaldehyde

and ammonia.

Pyridine and its derivatives are very important in industrial

field as well as in bio chemistry. 2,6-Pyridinediamine is used as an

intermediate for the synthesis of analgesic drugs. Phenazopyridine is an

example derived from 2,6-Pyridinediamine.

1.5 The thesis work

The use of secondary interactions a well-accepted strategy to

enhance the miscibility of immiscible polymers, and miscible polymer mixtures

based on hydrogen bonding. This is result in interesting and enhanced polymeric

properties[12,13]. The use of hydrogen bonds offers the advantage

that they involve distinct donor and acceptor sites, and are very directional.

In that way they offer more possibilities for structural design than forces

that are symmetric and non-directional as e.g. ion-ion interactions.

In our case, we will improve Tg of polystyrene based on

secondary interactions. Knowledgably crosslinking can increase Tg of polymers.

However, nobody tried to use the method because few crosslinkage in polystyrene

will lead to worse rheological property.

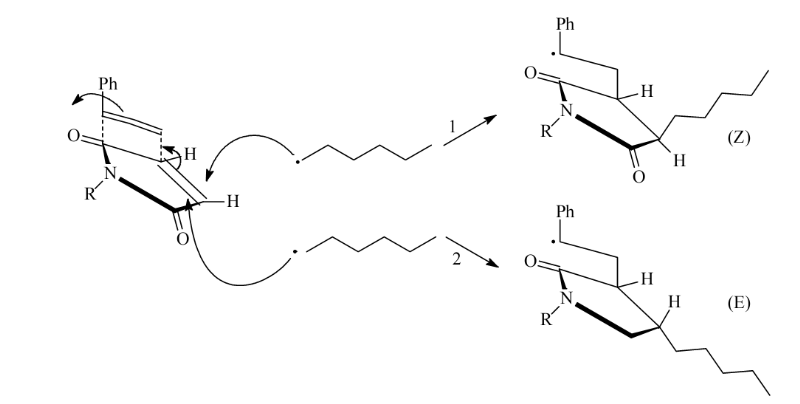

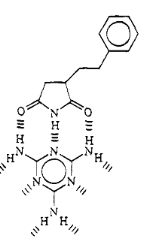

The arrangement of hydrogen bond donors and acceptors of

maleimide, which are involved in hydrogen bonding in the complex with melamine,

suggest that it should be possible to complex one melamine molecule to three

imides units.

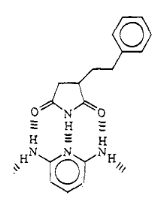

Fig 1-7 Proposed Structure of

Maleimide/styrene interactions with melamine

Fig 1-8 Proposed Structure of

Maleimide/styrene interactions with 2,6 diaminopyridine

In general, the binding strength of multiple hydrogen bonded

complexes is depending on the strength of the individual hydrogen bonds in the

array, and the number of hydrogen bond. Different hydrogen Donor(D) and

hydrogen acceptor (A) arrays can be obtained e.g. a triple bond( DDD-AAA array,

DDA-AAD array, DAD-ADA array)[12]. The DAD-ADA triple hydrogen bond array is

frequently used in organic chemistry due to its synthetic availability.

The use of a hydrogen bonding unit possessing two or more

interaction sites should result in network formation. It is a new, simple,

economical method to prepare polystyrene with higher Tg based on hydrogen

bonding crosslinkage between melamine and imide in the polystyrene prepared by

free radical copolymerization of styrene and few amount of maleimide. The

thermoreversible properties of hydrogen bond make the polystyrene have good

rheological properties with higher Tg.

In order to reveal the interaction between imide and melamine,

we used 2,6-diaminopyridine to replace melamine to complex with imide from SMA.

Both of them should complex with imide by DAD-ADA arrays shown in the Fig.1-7

and Fig.1-8.

Chapter 2 Experimental

2.1 Materials

Styrene was distilled under vacuum and stored in a freezer

until use. Maleimide 2,6-diaminopyridine were used commercially. AIBN

(2,2'-azobutironitrile) was recrystallised from methanol before use. DMSO was

purified and dried by standard techniques before use. CH3OH and

CH2Cl2 were used commercially.

2.2 Instruments

1H-NMR of copolymer samples were taken in

CDCl3 on a Bruker 600 MHz spectrophotometer with DMSO as a solvent.

The glass temperature transition was determined by differential scanning

calorimeter (DSC) and was performed on a Perkin Elmer Pyris 1 under nitrogen

with a scan rate of 10o C/min. The glass temperature transition Tg

is the midpoint in the heat-capacity change.

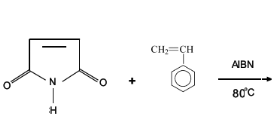

2.3 Synthesis of random copolymers of styrene and

maleimide

Copolymer of styrene and maleimide were prepared by a free

radical copolymerization using AIBN as the radical initiator and DMSO as

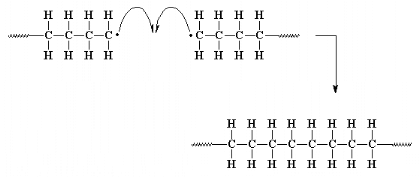

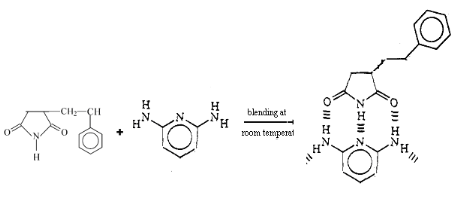

solvent. The synthesis of random copolymers of styrene and maleimide (Fig. 2-1)

which can serve as an example was performed as follow:

Styrene and Maleimide solution was prepared in DMSO. Styrene

solution was added with AIBN (80% w/w of the total monomer concentration) in a

3-necked round-bottomed flask equipped with a reflux condenser, mechanical

stirrer and nitrogen inlet (septum and a long needle). Maleimide solution was

added dropwise with AIBN (20% w/w of the total monomer concentration) shortly

and slowly. The polymer solution was precipitated in water and the resulting

polymer was dissolve in CH2Cl2 and precipitated in

CH3OH, then dried in vacuum at 60oC.

Fig 2-1 Synthesis Copolymerization of

Styrene and Maleimide

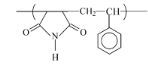

2.4 preparation of Blends of Styrene/Maleimide

copolymer and melamine or 2,6-diaminopyridine

Co-precipitation method was used to blend melamine or

2,6-diaminopyridine with imides containing copolymers. A

series of experiments was done to blend Styrene-Maleimide copolymers with

melamine or 2,6-diaminopyridine. Copolymers based on

styrene-maleimide were mixed homogenously with various amounts of melamine and

carefully dissolved in DMSO for 30 minutes, then co-precipitated in water. The

resulting polymer was dissolve in CH2Cl2 and precipitated

again in CH3OH then dried in vacuum at 50oC. After

filtration, washing and drying the yield of the blend was determined

[7].

Fig 2-2 blend of Styrene-Maleimide and

Melamine

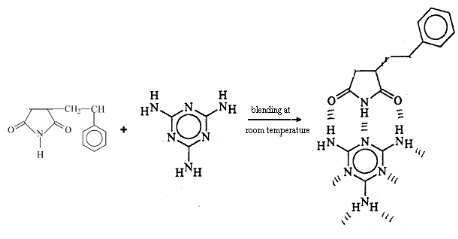

Fig 2-3 Blend of Styrene-Maleimide and

2,6-diaminopyridine

Chapter 3 Results and discussion

3.1 Characterization of copolymer of styrene and

maleimide

3.1.1 1H-NMR Spectra

In order to characterize the random styrene-maleimide

copolymer, 1H-NMR measurement was performed on a Bruker 600 MHz

spectrophotometer with DMSO as a solvent.

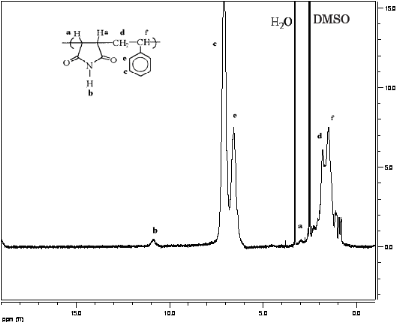

A typical 1H-NMR spectrum of copolymer Maleimide

Styrene is shown in figure 3-1.

Fig 3-1 1H-NMR spectrum of random

copolymer Styrene-Maleimide at ratio 18.8/1

The characteristic spectrum was found for different ratio of

Styrene-Maleimide

The 1H-NMR spectrum shows the expected resonance

for the aromatic protons of polystyrene (c and e; ä~6.0-7.6 ppm proton

signals of the -CH= group of Styrene ) and imine protons of Maleimide

(b; ä~ 11.2ppm).

The broad signals from 1 to 3 ppm are

assignable to CH (a and f) and CH 2

(d) protons of the main chain. Therefore, this spectrum

confirms the presence of Maleimide-styrene copolymer [15].

All of the 1H-NMR spectra of random copolymer of

Styrene-Maleimide at different compositions have shown the same characteristics

bands.

3.1.2 Copolymer composition

1H NMR spectroscopic analysis has been established

as a powerful tool for the determination of copolymer compositions because of

its simplicity, rapidity and sensitivity. The average composition ratio of the

copolymer samples was determined from the corresponding 1H NMR

spectra. The assignment of the resonance peaks in the 1H NMR

spectrum leads to the accurate evaluation of the content of each kind of

monomeric unit incorporated into the copolymer chains.

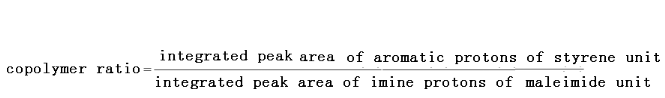

Thus, the Copolymer ratio of SMA was calculated by measuring the

integrated peak areas of aromatic protons of styrene unit (signal c and e) and

imine proton of Maleimide (signal b). Let B be the integrated peak areas of

aromatic protons of styrene monomer and A is the integrated peak areas of imine

proton of Maleimide. The polystyrene unit contains five aromatic protons active

in resonance and the maleimide unit contains one imine proton, the following

expression is used to determine the composition of copolymer:

Table 3-1 Calculation of

integrated peak area of protons and mole compositions of copolymers

I-V

|

Copolymer

|

IAromatic

|

IImide

|

A

|

B

|

[Styr]/ [Mal]

|

|

I

|

28.832

14.843

|

1.000

|

1.000

|

43.675

|

8.7

|

|

II

|

1.000

0.5473

|

0.0233

|

0.0233

|

1.5473

|

13.2

|

|

III

|

1.000

0.5741

|

0.0167

|

0.0167

|

1.5741

|

18.8

|

|

IV

|

1.000

0.5581

|

0.0122

|

0.0152

|

1.5581

|

25.5

|

|

IV

|

1.000

0.3540

|

0.0153

|

0.0153

|

1.3540

|

17.7

|

I

Aromatic Integrated peak area of aromatic protons of

styrene unit.

Imide Integrated

peak area of an imine proton of Maleimide.

3.2 Copolymerization of styrene and maleimide

The random copolymer styrene-maleimide was easily obtained by

radical polymerization in DMSO using AIBN as the initiator. To control the

content of maleimide in copolymer, we performed the synthesis at different

conditions to copolymerize Maleimide and Styrene, and obtained copolymers with

identical main chain structure but with a different yield from 37.3 % to 89%.

As we mentioned before, Maleimide and Styrene could constitute the charge

transfer complex, so we chose dropwise addition of maleimide during the

polymerization.

Table 3-2 Effect of styrene/maleimide ratio on

yield

|

Experience

|

[Styr]/[Mal]

|

Reaction time/h

|

Temp/oC

|

Masse AIBN/%

|

Monomer Conc./M

|

Yield/%

|

[st]/[imide]

|

|

1

|

10/1

|

6

|

80

|

5

|

0.0476

|

39.4

|

8.7/1

|

|

2

|

15/1

|

44.5

|

13.2/1

|

|

3

|

20/1

|

80.0

|

18.8/1

|

|

13

|

30/1

|

89.0

|

25.5/1

|

Table 3-3 Effect of initiator on yield

|

Experience

|

[Styr]/[Mal]

|

Reaction time/h

|

Temp/ oC

|

Masse AIBN/%

|

Monomer Conc./M

|

Yield /%

|

|

4

|

20/1

|

6

|

80

|

1

|

0.0476

|

37.3

|

|

5

|

2

|

48.8

|

|

6

|

4

|

59.8

|

|

3

|

5

|

80.0

|

Table 3-4 Effect of temperature on yield

|

Experience

|

[Styr]/[Mal]

|

Reaction time/h

|

Temp/oC

|

Masse AIBN/%

|

Monomer Conc./M

|

Yield /%

|

|

7

|

20/1

|

6

|

60

|

5

|

0.0476

|

20.8

|

|

8

|

70

|

40.0

|

|

3

|

80

|

80.0

|

|

9

|

90

|

85.0

|

Table 3-5Effect of reaction time on yield

|

Experience

|

[Styr]/[Mal]

|

Reaction time/h

|

Temp/oC

|

Masse AIBN/%

|

Monomer Conc./M

|

Yield /%

|

|

10

|

20/1

|

4

|

80

|

5

|

0.0476

|

67.0

|

|

11

|

5

|

72.0

|

|

3

|

6

|

80.0

|

|

12

|

8

|

81.0

|

From these results we conclude that the ratio of the

copolymerization affects much more the yield.

Table 3-2 show that the yield of the copolymer increase with

the ratio of [Styrene]/[Maleimide]. That indicates maleimide introduction slows

the polymerization rate of styrene. However, the ratio of [St]/[imide] in the

copolymer is less than their monomer ratio counterpart, which means Maleimide

is easy to copolymerize with styrene.

Table 3-5 indicates that time is a parameter very important in

the copolymerization. As we described above, maleimide was added to the

solution shortly and slowly to avoid the formation of alternative copolymers

and to lead predominantly to the formation of random copolymer. To extend the

time reaction favors the formation of random copolymer. There is no

improvement in yield at reaction time of over 6hrs. that indicates effect of

maleimide on copolymerization is negligible. Table 3-3 and 3-4 have shown

respectively an increase of yield when the initiator and the temperature are

changed drastically. This result is demonstrated by the fact that the

copolymerization reaction is depending of the amount of initiator used and the

temperature required to activate the copolymerization.

3.3 Blends of the styrene/maleimide copolymers and

melamine

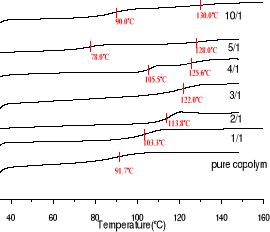

DSC curves of the blends of the copolymers

I-IV(as shown in Table 3-1) with melamine are

shown in Fig 3-2 and their Tg values are presented in Table3-6.

Table 3-6 Effect of imide /melamine ratio on

Tg

|

Experience

|

[imide]/[Mela]

|

[Styr]/ [Mal]

|

Tg/oC

|

|

F

|

1/1

|

18.8/1

|

103.3

|

|

G

|

1/2

|

113.8

|

|

H

|

1/3

|

122.0

|

|

I

|

1/4

|

125.6

105.5

|

|

J

|

1/5

|

128.0

78.0

|

|

K

|

1/10

|

130.0

90.0

|

Fig 3-2 DSC traces of blends with different

molar concentration ratio melamine to imide in the copolymer with maleimide

molar concentration of 5.05 %

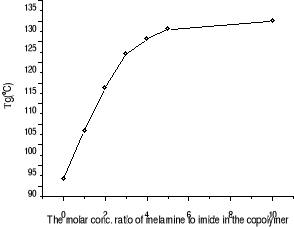

As shown in Fig3-2 and in Fig3-3, addition of

melamine results in a dramatic increase of Tg up to melamine concentration

ratio of 3 times to imide in the copolymer which correspond to Tg equal

122oC. In this case, Tg is 30oC higher than the pure

copolymer. At the melamine:imide ratio of 10:1, even 40oC is reached

with Tg of 130oC. However the more addition of melamine results in

presence of two value of Tg from the melamine: imide ratio of 4:1 to of 10:1.

It well known there is triple-hydrogen bonding between melamine and imide unit.

Recently, Ronald F. M [5,7,12] proposed that one melamine molecule interacts

with three imide units, leading to a three-dimensional hydrogen bonded

network.

Figure 3-3 Dependence of Tg on the

ratio of melamine to imide in the copolymer

Tg increase of our copolymer in presence of melamine

attributes to this kind of crosslinkage restricting the motion of polystyrene

segments. The more crosslinkage in the blend corresponds to the higher Tg of

the blend. However, Maleimide contains in our copolymers is 20 times less than

Ronald's, and randomly distribute along the chain, which restricts the imides

together to interact with melamine. Therefore, more melamine is needed to build

a crosslinking site. As Figure 3-3 shown, melamine:imide ratio elevation from

3:1 to 10:1 still increases the Tg although slowly, suggesting crosslinkage

density still increases. From the melamine: imide ratio of 4:1 to of 10:1, the

presence of another Tg at lower temperature in case of melamine: imide ratio of

4/1, 5/1 and 10/1 is reasonably explained as the presence of free melamine

which acts as a plasticizer.

In order to increase crosslinkage sites, we prepared a series

of blends with different styrene/maleimide ratios. The results were given in

Table 3-8 and Fig 3-4.

Table 3-7 Effect of styrene/maleimide ratio on

Tg

|

Experience

|

[Styr]/ [Mal]

|

Tg/oC

|

|

A

|

polystyrene

|

100.1

|

|

B

|

8.1/1

|

84.6

|

|

C

|

13.2/1

|

87.4

|

|

D

|

18.8/1

|

91.7

|

|

E

|

25.5/1

|

93.0

|

Table 3-8 Effect of styrene/maleimide ratio on

Tg

|

Experience

|

[Styr]/ [imide]

|

[imide]/[Mela]

|

Tg/oC

|

|

L

|

8.1/1

|

1/5

|

106.9

|

|

M

|

13.2/1

|

123.3

|

|

N

|

18.8/1

|

128.0

78.0

|

|

O

|

25.5/1

|

146.2

89.0

|

|

P

|

8.1/1

|

1/3

|

109.0

|

|

Q

|

13.2/1

|

113.0

|

|

H

|

18.8/1

|

122.0

|

|

R

|

25.5/1

|

127.0

74.0

|

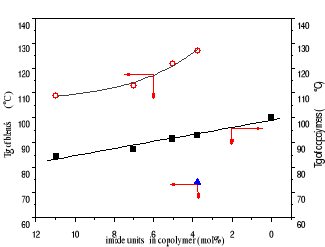

Figure 3-4 Dependence of Tg on imide contents

in copolymer (black spot)

Blends with molar ratio of melamine to imide 3:1(red spot)

Figure 3-4 reveals that Tg of copolymer decreased in a linear

function with maleimide content due to the flexibility of maleimide units.

However, Tg of all blends with melamine: imide ratio of 3:1 is much higher, at

least 25C, than a correspondent copolymer, and is an exponential decay

relationship with imide content. Blend of copolymer with the fewest imide

content([styrene]/[imide] 25.5/1) has the highest Tg, 127oC.

At the same melamine:imide ratio of 3:1, melamine isn't enough

to saturate imide units in the blends with higher imide content. However,

melamine is too much to complex with imide unit in the blend with imide content

of 25.5/1. It is confirmed by appearing another Tg at 74 oC. So, Tg

of blends with higher imide content must be much higher if more melamine is

used. With melamine: imide ratio of 5:1, we prepared a series of blends and

tested their Tg, shown in Table 3-8. their Tgs are much higher than ones of

blends with melamine: imide ratio of 3:1.

Moreover, in the procedure of preparation of blends, it is

observed that blends are readily soluble in DMSO, even in

CH2Cl2, this indicate that crosslinling are present in

our blends and is based on secondary interactions.

3.4 Blends of the copolymer and 2,6-diaminopyridine

In order to evaluate the effect of crosslinking of melamine on

the Tg of blend, we prepared a series of blend of Diaminopyridine(DAP) and

Styrene/Maleimide copolymer with different styrene/maleimide ratios. DAP is

analogue structure to melamine. They both can form a complex with imide through

a triple hydrogen bonds in the manner of DAD-ADA arrays, however without

crosslinkage is formed in the blends of DAP and Styrene/Maleimide copolymer

owing to difference of DAP and melamine in structure, as showed in Fig. 1-7 and

Fig.1-8.

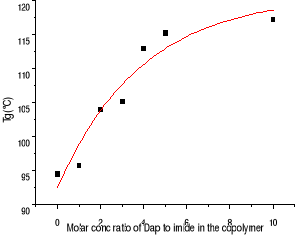

DSC curves of the blends of Diaminopyridine and

Styrene/Maleimide copolymer are shown in Figure 3-5 and their

Tg values are presented in Table3-9.

Table 3-9 Effect of imide/Dap ratio on Tg

|

Experience

|

[imide]/[Dap]

|

[Styr]/ [imide]

|

Tg/oC

|

|

control

|

1/0

|

17.7/1

|

94.2

|

|

S

|

1/1

|

95.7

|

|

T

|

1/2

|

103.9

|

|

U

|

1/3

|

105.2

|

|

V

|

1/4

|

113.0

|

|

W

|

1/5

|

115.2

78.1

|

|

X

|

1/10

|

117.2

76.5

|

Figure 3-5 Dependence of Tg on the

ratio of DAP to imide in the copolymer

The dependence of Tg on the ratio of DAP to imide showed that

Tgs of blends are increasing with addition of DAP, as same as blends of the

copolymer with melamine. Single Tg is shown till DAP concentration ratio of 4

times to imide, which correspond to Tg equal 113oC . Then, two Tg is

found although one is still elevated. the behavior is found in blends of the

copolymer with melamine.

It is known there is triple-hydrogen bonding between DAP and

imide unit. Tg increase of our copolymer in presence of DAP attributes to this

kind of triple-hydrogen bonding existing in the blend and restricting the

motion of polystyrene segments, making the copolymer look like a copolymer of

styrene and complex of maleimide with DAP.

However, the Tg increase of the blends is lower ones of blends

of the copolymer with melamine. Contrary to the melamine, DAP molecule can not

have crosslinkng with imide unit. So the results confirm there are truly

crosslinking formation in blends of the copolymer with melamine.

Chapter 4 Conclusion

Tg of polystyrene, a common polymer, is dramatically elevated

based on crosslinkage between introduced imide units and melamine. Polystyrene

with imide molar concentration of 5.05% has Tg of 122oC in the

presence of melamine, 22 oC higher than polystyrene, which will

extend application of polystyrene. At high ratio of melamine to imide, two Tgs

are observed, one is higher than 122oC but another much lower. The

existence of two Tg is due to the fact that free melamine is acting as

plasticizer.

Diaminopyridine also increase Tg of polystyrene. In this case,

the blend looks like a copolymer of styrene with a big monomer, complex of

maleimide and Diaminopyridine. but increment is less than melamine owing to

lack of crosslinking between them.

The secondary interactions between melamine or Diaminopyridine

with polystyrene containing imide is confirmed by their blends readily soluble

in DMSO and in CH2Cl2.

References Notes

|

[1]

|

Kaj Backfolk et al;Determination of the glass transition

temperature of latex films:comparaison of various methods,''Department of

Physical Chemistry Akademi University ,Finland(2007)

|

|

[2]

|

Victor Morais,Random alternate and diblock

copolymers,Departement Materials,University Comlutense,Madrir,Spain(2005)

|

|

[3]

|

Xinliang Yu, Xueye Wang, Hanlu Wang, Aihong Liu and Cuili

Zhang , Journal of Molecular Structure: THEOCHEM, Volume 766, Issues 2-3,

15 August 2006, Pages 113-117

|

|

[4]

|

Xinliang Yuet al.;Prediction of the glass transition

temperatures of styrenic copolymers using a QSPR based on the DFT

method,College of Chemistry ,Xiangtan University ,people's of republic of

China(2006)

|

|

[5]

|

Kumar A, Galaev IY, Mattiasson B. Affinity precipitation of

á-amylase inhibiter from wheat metal by metal chelate affinity binding

using Cu (\u8545centsò) loaded copolymers of 1-vinylimidazole with

N-isopropy- acrylamide[J]. Biotechnol. Bioeng., 1998, 59: 693-704

|

|

[6]

|

Ronald lange and al.;Supramolecular Polymer Interaction based

on the alternating copolymer of styrene and maleimide,laboratory of organic

chemistry ,Eindhoven university,The Netherlands(1994); Supramolecular Polymer

Interaction using melamine, Laboratory of organic chemistry , Eindhoven

university,The Netherlands(1996)

|

|

[7]

|

Kotera,M;Lehn,J.chem.Soc.,Chem Comm.1994,197

|

|

[8]

|

Ronald lange ,Polymer blends based on the imidiaminotriazine

triple hydrogen bond ,Laboratory of organic chemistry , Eindhoven

university,The Netherlands(1997)

|

|

[9]

|

Mirzaagha babazadeh,thermal stability and high glass

transition temperature of 4-choloromethyl styrene polymers,Departement of

Applied Chemistry,islamic Azad university ,Iran(2006)

|

|

[10]

|

Bill meyer,;J.R.;Textbook of Polymer Science

3rdEd.;Wiley interscience,New york,USA(1984)

|

|

[11]

|

Melamine as a dietary nitrogen source for ruminants",

G.L.Newton and P.R.Utley, Journal of Animal Science, vol.47, p1338-44, 1978

|

|

[12]

|

E.E. Simanek, X. Li, I.S. Choi, G.M. Whitesides, "Cyanuric

Acid and Melamine: A Platform for the Construction of Soluble Aggregates and

Crystalline Materials", Comprehensive supramolecular chemistry, J.L. Atwood

ed., New York:Pergamon, Vol.9, 495 (1996).

|

|

[13]

|

Ronald lange and al.;Supramolecular polymer chemistry based on

melamine and maleimide-styrene copolymers,laboratory of organic chemistry

Eindhoven university,The Netherlands(1997)

|

|

[14]

|

Coleman ,Specific interaction and the miscibility of polymer

Blends ,Technomic,Lancaster(1991)

|

|

[15]

|

Koji Ishizu,Chisato Takashi?????Takeshi Shibuya and Satoshi

Unichida, Dept. of organic materilas and Macr.,Int. research Centre of

Macro.scienceTokyo Inst. of Tech.,Tokyo,Japan (2003)

|

|

|