3.2 Copolymerization of styrene and maleimide

The random copolymer styrene-maleimide was easily obtained by

radical polymerization in DMSO using AIBN as the initiator. To control the

content of maleimide in copolymer, we performed the synthesis at different

conditions to copolymerize Maleimide and Styrene, and obtained copolymers with

identical main chain structure but with a different yield from 37.3 % to 89%.

As we mentioned before, Maleimide and Styrene could constitute the charge

transfer complex, so we chose dropwise addition of maleimide during the

polymerization.

Table 3-2 Effect of styrene/maleimide ratio on

yield

|

Experience

|

[Styr]/[Mal]

|

Reaction time/h

|

Temp/oC

|

Masse AIBN/%

|

Monomer Conc./M

|

Yield/%

|

[st]/[imide]

|

|

1

|

10/1

|

6

|

80

|

5

|

0.0476

|

39.4

|

8.7/1

|

|

2

|

15/1

|

44.5

|

13.2/1

|

|

3

|

20/1

|

80.0

|

18.8/1

|

|

13

|

30/1

|

89.0

|

25.5/1

|

Table 3-3 Effect of initiator on yield

|

Experience

|

[Styr]/[Mal]

|

Reaction time/h

|

Temp/ oC

|

Masse AIBN/%

|

Monomer Conc./M

|

Yield /%

|

|

4

|

20/1

|

6

|

80

|

1

|

0.0476

|

37.3

|

|

5

|

2

|

48.8

|

|

6

|

4

|

59.8

|

|

3

|

5

|

80.0

|

Table 3-4 Effect of temperature on yield

|

Experience

|

[Styr]/[Mal]

|

Reaction time/h

|

Temp/oC

|

Masse AIBN/%

|

Monomer Conc./M

|

Yield /%

|

|

7

|

20/1

|

6

|

60

|

5

|

0.0476

|

20.8

|

|

8

|

70

|

40.0

|

|

3

|

80

|

80.0

|

|

9

|

90

|

85.0

|

Table 3-5Effect of reaction time on yield

|

Experience

|

[Styr]/[Mal]

|

Reaction time/h

|

Temp/oC

|

Masse AIBN/%

|

Monomer Conc./M

|

Yield /%

|

|

10

|

20/1

|

4

|

80

|

5

|

0.0476

|

67.0

|

|

11

|

5

|

72.0

|

|

3

|

6

|

80.0

|

|

12

|

8

|

81.0

|

From these results we conclude that the ratio of the

copolymerization affects much more the yield.

Table 3-2 show that the yield of the copolymer increase with

the ratio of [Styrene]/[Maleimide]. That indicates maleimide introduction slows

the polymerization rate of styrene. However, the ratio of [St]/[imide] in the

copolymer is less than their monomer ratio counterpart, which means Maleimide

is easy to copolymerize with styrene.

Table 3-5 indicates that time is a parameter very important in

the copolymerization. As we described above, maleimide was added to the

solution shortly and slowly to avoid the formation of alternative copolymers

and to lead predominantly to the formation of random copolymer. To extend the

time reaction favors the formation of random copolymer. There is no

improvement in yield at reaction time of over 6hrs. that indicates effect of

maleimide on copolymerization is negligible. Table 3-3 and 3-4 have shown

respectively an increase of yield when the initiator and the temperature are

changed drastically. This result is demonstrated by the fact that the

copolymerization reaction is depending of the amount of initiator used and the

temperature required to activate the copolymerization.

3.3 Blends of the styrene/maleimide copolymers and

melamine

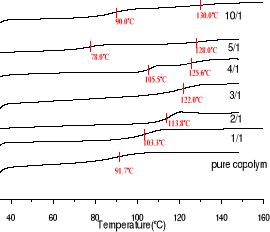

DSC curves of the blends of the copolymers

I-IV(as shown in Table 3-1) with melamine are

shown in Fig 3-2 and their Tg values are presented in Table3-6.

Table 3-6 Effect of imide /melamine ratio on

Tg

|

Experience

|

[imide]/[Mela]

|

[Styr]/ [Mal]

|

Tg/oC

|

|

F

|

1/1

|

18.8/1

|

103.3

|

|

G

|

1/2

|

113.8

|

|

H

|

1/3

|

122.0

|

|

I

|

1/4

|

125.6

105.5

|

|

J

|

1/5

|

128.0

78.0

|

|

K

|

1/10

|

130.0

90.0

|

Fig 3-2 DSC traces of blends with different

molar concentration ratio melamine to imide in the copolymer with maleimide

molar concentration of 5.05 %

As shown in Fig3-2 and in Fig3-3, addition of

melamine results in a dramatic increase of Tg up to melamine concentration

ratio of 3 times to imide in the copolymer which correspond to Tg equal

122oC. In this case, Tg is 30oC higher than the pure

copolymer. At the melamine:imide ratio of 10:1, even 40oC is reached

with Tg of 130oC. However the more addition of melamine results in

presence of two value of Tg from the melamine: imide ratio of 4:1 to of 10:1.

It well known there is triple-hydrogen bonding between melamine and imide unit.

Recently, Ronald F. M [5,7,12] proposed that one melamine molecule interacts

with three imide units, leading to a three-dimensional hydrogen bonded

network.

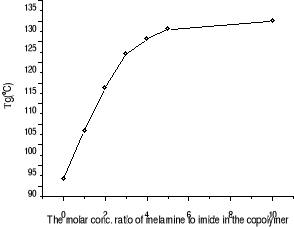

Figure 3-3 Dependence of Tg on the

ratio of melamine to imide in the copolymer

Tg increase of our copolymer in presence of melamine

attributes to this kind of crosslinkage restricting the motion of polystyrene

segments. The more crosslinkage in the blend corresponds to the higher Tg of

the blend. However, Maleimide contains in our copolymers is 20 times less than

Ronald's, and randomly distribute along the chain, which restricts the imides

together to interact with melamine. Therefore, more melamine is needed to build

a crosslinking site. As Figure 3-3 shown, melamine:imide ratio elevation from

3:1 to 10:1 still increases the Tg although slowly, suggesting crosslinkage

density still increases. From the melamine: imide ratio of 4:1 to of 10:1, the

presence of another Tg at lower temperature in case of melamine: imide ratio of

4/1, 5/1 and 10/1 is reasonably explained as the presence of free melamine

which acts as a plasticizer.

In order to increase crosslinkage sites, we prepared a series

of blends with different styrene/maleimide ratios. The results were given in

Table 3-8 and Fig 3-4.

Table 3-7 Effect of styrene/maleimide ratio on

Tg

|

Experience

|

[Styr]/ [Mal]

|

Tg/oC

|

|

A

|

polystyrene

|

100.1

|

|

B

|

8.1/1

|

84.6

|

|

C

|

13.2/1

|

87.4

|

|

D

|

18.8/1

|

91.7

|

|

E

|

25.5/1

|

93.0

|

Table 3-8 Effect of styrene/maleimide ratio on

Tg

|

Experience

|

[Styr]/ [imide]

|

[imide]/[Mela]

|

Tg/oC

|

|

L

|

8.1/1

|

1/5

|

106.9

|

|

M

|

13.2/1

|

123.3

|

|

N

|

18.8/1

|

128.0

78.0

|

|

O

|

25.5/1

|

146.2

89.0

|

|

P

|

8.1/1

|

1/3

|

109.0

|

|

Q

|

13.2/1

|

113.0

|

|

H

|

18.8/1

|

122.0

|

|

R

|

25.5/1

|

127.0

74.0

|

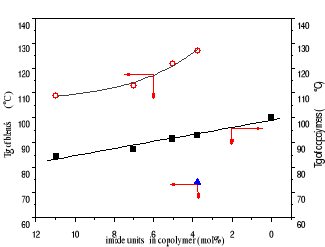

Figure 3-4 Dependence of Tg on imide contents

in copolymer (black spot)

Blends with molar ratio of melamine to imide 3:1(red spot)

Figure 3-4 reveals that Tg of copolymer decreased in a linear

function with maleimide content due to the flexibility of maleimide units.

However, Tg of all blends with melamine: imide ratio of 3:1 is much higher, at

least 25C, than a correspondent copolymer, and is an exponential decay

relationship with imide content. Blend of copolymer with the fewest imide

content([styrene]/[imide] 25.5/1) has the highest Tg, 127oC.

At the same melamine:imide ratio of 3:1, melamine isn't enough

to saturate imide units in the blends with higher imide content. However,

melamine is too much to complex with imide unit in the blend with imide content

of 25.5/1. It is confirmed by appearing another Tg at 74 oC. So, Tg

of blends with higher imide content must be much higher if more melamine is

used. With melamine: imide ratio of 5:1, we prepared a series of blends and

tested their Tg, shown in Table 3-8. their Tgs are much higher than ones of

blends with melamine: imide ratio of 3:1.

Moreover, in the procedure of preparation of blends, it is

observed that blends are readily soluble in DMSO, even in

CH2Cl2, this indicate that crosslinling are present in

our blends and is based on secondary interactions.

|