4.1.2. Experimental set up

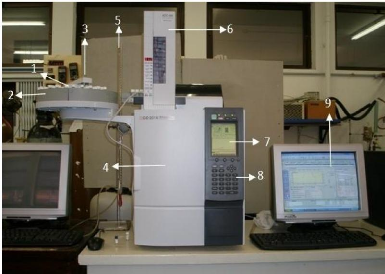

Experiments were performed using a Shimadzu GC-2014 gas

chromatograph apparatus, equipped with a thermal conductivity detector, an

auto-sampler and auto-injector. Retention times and chromatograms related to

each run were made available on a PC monitor by means of a GC solution

workstation software. The set up, shown in Photograph 4-1, is programmable so

that it can carry out injections of samples from 125 different vials and

acquire data with minimum human supervision.

Photograph 4-1: Gas-Liquid Chromatography

equipment.

1. Vials; 2. Tray; 3. Auto-sampler (arm); 4. Column oven; 5. Soap

bubble flow-meter; 6. Auto-

injector; 7. GC screen; 8. Operation panel; 9.

PC monitor

4.1.3. Experimental procedure

The experimental procedure used in this work has been well

documented by numerous authors (David et al. 2003, Letcher et al. 2003a,b and

Deenadayalu et al. 2005). To check for adsorption problems, two different

stainless steel columns of length 1 m and 4.1 mm inner diameter were used with

two different mass percent packings. To avoid adsorption effects, mass percent

packings of the ionic liquid that are large enough were used. Before packing,

the columns were washed with hot soapy water, rinsed with cold water and

flushed with acetone to minimize the drying time. The original and final masses

of the ionic liquid and chromosorb mixture were in agreement to within 0.0005

g. Measurements were done at different temperatures between (303.15 and 373.15)

K, i.e. (303, 313.15, 323.15, 333.15, 353.15, 363.15 and 373.15) K.

Reproducibility was checked by undertaking three experimental runs. It was

observed that retention times were reproducible within 0.05 minutes. The flow

rate of dry helium, the carrier gas, was determined with the aid of a soap

bubble flow meter placed at the outlet of the detector. The flow rates were

corrected for water vapour pressure and varied from 0.3 to 0.7

um3.s-1 .The carrier gas flow rate was allowed to

stabilize for at least 15 min prior to any series of runs. The pressure drop

through the column varied from (25 to 50) kPa, providing conducive retention

times and sharp peaks. The injected volumes ranged between 0.1 and 0.5 ul and

were considered small enough to comply with the condition of infinite dilution

of the solutes on the column. Both the injector and the detector were at

T = 523.15 K. More details on the experimental parameters and

variables needed to compute infinite dilution activity coefficients by means of

equation (3-10), are discussed below.

4.1.3.1 Temperature control

The equipment, not only controls the temperature using a

thermostat, but also displays its value

5

on the monitor. The column oven temperature was known with an

accuracy of #177; 0.01 K and a stability of 0.05 K. The design of the GC was

such that an electronically controlled thermostat was used to reliably control

the column temperature.

4.1.3.2 Pressure measurement

The outlet pressure which is the same as the atmospheric

pressure was measured with the aid of a digital barometer with an uncertainty

of #177;0.30 %. The pressure drop through the packed column was fixed by the

equipment, depending on the inert gas flow-rate set by the operator. The

uncertainty in the inlet pressure measurement was #177;0.50 %.

4.1.3.3 Flow-rate measurement

A bubble soap flow-meter consisting of a 100 ml calibrated

cylinder was used for the determination of helium flow rate. The uncertainty in

the flow rate measurement was estimated as #177;0.20 %.

4.1.3.4 Infinite dilution range

Injections between 0.1 and 0.5ul were considered small enough

to comply with the infinite dilution requirement. It is however advisable to

check whether the retention time for a solute at the selected injection volume

and flow rate remains the same as when it is part of a mixture.

4.1.3.5 Column packing

This is the most critical step when undertaking measurements

via the Gas-Liquid Chromatography technique. Large error margins are caused by

a careless column packing. The uncertainty in determining the mass of the

solvent loaded into the column was #177;0.03 %.

Column cleaning

The column was washed with soapy water and flashed with acetone

to facilitate drying with air.

Determination of solvent number of moles

The following procedure was employed:

1. The mass of an empty flask was measured using a digital

balance;

2. Chromosorb, the solid support for the solvent was added to the

flask and weighed;

3. The amount of solvent to be added was roughly calculated on

the basis of the desired percent loading of the solvent;

4. The solvent was added and its weight found accurately.

Coating the support with the IL

Dichloromethane was added to the flask content to distribute

the solvent evenly on chromosorb. Thereafter, a rotary evaporator was used to

remove the Dichloromethane. This step ended when the mass of the mixture in the

content was equal to the one measured before adding dichloromethane.

Filling the column

The support loaded with IL was filled in the column with the

aid of a vacuum pump. One had to

make sure that the load was equally

distributed inside the column. The mass of the packed

column had to be known before and after each series of runs to

check for a probable elution of the solvent.

|