4.2. The inert gas

stripping technique

4.2.1. Chemicals

To validate the method, experiments were performed with NMP as

solvent whereas n-hexane, hex-1-ene, hex-1-yne, methanol, cyclohexane, benzene

and acetone were used as solutes in the ionic liquid

trihexyltetradecylphosphonium bis (trifluoromethylsulfonyl) imide, [3C6C14P]

[BTI]. Appendix C provides additional information about the solvents, including

their source, purity, density and refractive index. No further purification was

undertaken for the solutes as they were of high purity. Solvents were purified

by heat treatment under vacuum.

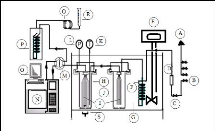

4.2.2. Experimental Set-up

As part of this study, it was intended to construct an entire

inert gas stripping set up with an equilibrium cell able to accommodate small

volumes of samples, less than 50 g. This was a necessity since ionic liquids

are very expensive chemicals. The second reason why a dilutor cell was needed

is for systems that are not suitable when using the GLC technique. Examples of

these are systems involving solutes that are solid at room temperature, solvent

mixtures and those leading to a very long retention time. Design parameters for

the dilutor cell were discussed in the previous chapter. The greatest part of

the design work was centered on the dilutor cell as it is the most determinant

piece of the set up performance. Figure 4-1 presents the simplified flow

diagram of the set up used in this study, which is similar to the one described

by Krummen et al. (2000) and Coquelet and Richon (2005). Photograph 4-2 gives

the experimental set up of the inert gas stripping apparatus.

Figure 4-1: Flow diagram of the experimental

set up for the inert gas stripping method.

A-Helium, Nitrogen and air supply

for the GC; B- Nitrogen line; C-Valve; D- flow regulator; E-

Immersion

temperature controller; F-Coil tube (Heat exchanger); G-Transparent acrylic

bath; H- Dilutor

cell; I-Capillaries; J-Presaturation cell; K-Platinum

resistance thermometer; L-Pressure transducer; M-

Sampling valve; N-GC

apparatus; O-PC monitor; P-Cold trap; Q- Coil tube (Heat exchanger);

R-Soap

bubble flow-meter; S-Magnetic stirrer.

4.2.2.1. Gas cylinders

Four gases are used in this work:

· Nitrogen as stripping gas;

· Helium as carrier gas for the GC apparatus;

· Air and Hydrogen to produce the ignition flame for the GC

(FID only).

The four cylinders containing the above gases are fitted with

regulators. Nitrogen flow rate is controlled by a smaller regulator. Its value

is determined by means of a soap bubble flow meter.

4.2.2.2. Water bath

An 18-litre transparent acrylic water bath, with maximum

allowed temperature of 70 oC, was used to accommodate the cells

during experiments. During experiments, leaks could be easily detected by the

observation of gas bubbles, due to the transparency of the bath. A Haake

Difisons temperature controller kept the water in the bath at a constant

temperature set before each run. The nitrogen line (1/4 inch inner diameter and

12 m long) was coiled and immersed in the water bath to allow the gas to

equilibrate to the set-point temperature before entering the cells. In order to

reduce heat loss to the atmosphere, the water surface in the bath was

completely covered with polystyrene chips. The temperature stability of the

bath was #177;0.1 K.

4.2.2.3. Cells

The two glass cells are identical and have a total volume of

50 cm3 each. They were made for the purpose of this work by a Durban

glass blower, Mr. Peter Siegling. Metallic parts were manufactured and fitted

by the School of Chemical Engineering workshop staff members, Mr. Ken Jack and

Mr. Kelly Robertson. The shape is similar to the cells previously used by other

researchers (Coquelet and Richon 2005). Mass transfer considerations discussed

by Richon et al. (1980) were taken into account to determine the cell height

using equation (3-95), assuming

the degree of the equilibrium attainment = 0.99 From the

literature, ranges of different

properties related to FILs (See table 2-2) were used in

equation (3-95) to find out the most suitable height for the cell. The same

procedure was used by Li et al. (1993) to find out the optimum height of the

dilutor cell used in the study of IDAC`s for nonelectrolytes solutes in water.

For systems involving ionic liquids, the presaturator cell was removed. As

shown in Photograph 4-3, the dilutor cell is fitted with ten stainless steel

capillaries (0.1 mm inner diameter) purchased from Anatech, through which the

stripping gas is introduced. During experiments, they should be placed in such

a way that bubbles are not directed to the vortex. This will prevent bubbles

coalescence (George 2008). A class A Pt-100 temperature sensor (length 250 mm,

outer diameter 3 mm and limiting error of 0.25 oC) fitted with

stainless steel pot seal and a Sensotec pressure transducer are inserted in

order to measure the temperature of

the mixture and the pressure in the dilutor cell. To obtain

accurate readings, both sensors had to be calibrated. A CTH 6500 digital

thermometer (accuracy: #177;0.03 %) and a CPH 6000 pressure calibration

standard (accuracy: #177;0.1 %) for temperature and pressor sensor

calibrations, respectively. The bolt (G) along with the Teflon piece (H) seal

the cell to ensure that no portion of nitrogen flows through other channels

than the provided capillaries. Agitation of the solution contained in the cell

is achieved by means of a magnetic stirrer. Other features of the designed cell

are given by Photograph 4-3.

|