4.2.2.4. Cold trap

The stream leaving the dilutor cell contains not only

nitrogen, but also solute and probably solvent vapours. A cold trap serves as a

separation unit to ensure that the flow rate determined by the soap bubble

flow-meter is actually the one of nitrogen which is required in the infinite

dilution activity coefficient computation equation. Failure to condense solute

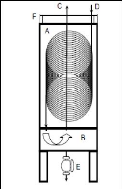

and solvent vapours will lead to inaccurate data. The cold trap as shown in

figure 4-2 consists of two chambers. The upper chamber (A) contains an

ice-acetone solution in which a 1/4 inch ID copper coil is completely immersed.

The outlet gas stream from the dilutor cell flows through the coils and ends

its path in the lower chamber (B) where the condensate is trapped. Nitrogen,

the only gaseous component after this process, rises up to exit through the

pipe (C) and makes its way to the soap bubble flow-meter (J). Valve (E) can be

opened to drain out the liquid captured in chamber (B).

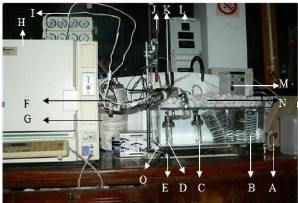

Photograph 4-2: Set-up of the inert gas

stripping apparatus. A-flow regulator; B-Coil tube

(Heat exchanger);

C-Presaturation cell; D- Dilutor cell; E-Magnetic stirrer; F-Sampling

valve;

G-Cold trap; H-GC apparatus; I-GC lines; J-Soap bubble flow-meter;

K-Pressure transducer; L-

Pressure and temperatures displays; M-Immersion

temperature controller; N-Polystyrene chips;

O-Transparent acrylic bath.

Photograph 4.3: The dilutor cell. A-Glass

still; B-Capillaries; C-Temperature probe (Pt 100);

D-Gas inlet; E-Gas

outlet; F-Pressure transducer tube; G-Bolt (seal); H-Teflon plug (seal).

Figure 4-2: Cross Section of the cold trap to

illustrate its inner workings (George 2008)

A - Upper chamber, B - lower

chamber, C - gas inlet, D - non-condensable gas outlet, E -

release valve, F

- lid.

4.2.2.5. Gas Chromatography apparatus

In this work, a SHIMADZU GC 14A gas chromatograph equipped

with a FID detector was used. The FID has the advantage over the TCD to be very

sensitive to small amounts of solutes injected. GC settings and column

conditions during experiments are displayed in table 4-1. To avoid condensation

of the solute as the stream flows from the dilutor cell outlet to the GC

injection port via the six-port sampling valve, these lines had to be heated

and thermostated at a temperature approximately 40 oC higher than

the system temperature (Krummen et al. 2000).

Table 4-1: GC specification and set-up.

Column CRS; 2m x 1/8`; Packed column

GC Program Clarity work station

Detector type FID

Carrier gas Helium

Injection Port Temperature 493.15 K

Column Oven Temperature 393.15 K-453.15 K

Detector Temperature 493.15 K

4.2.3. Experimental procedure

First, the cells were cleaned and thereafter filled with the

required components. The solvent was poured into each cell. The mass of the

solvent in the dilutor cell had to be known accurately. The solute was injected

into the dilutor cell in very small concentration to comply with the infinite

dilution requirement, less than 0.001 mole fraction. The injected volume ranged

between (10 and 25). Density data of the solvent (given in appendix C) were

used to

determine by difference the vapour phase volume. The cells

were then sealed and fitted onto the set up. The equipment was checked for

leaks, the cold trap upper chamber was filled with acetone-ice mixture, the GC

apparatus and all electrical equipments with desired settings were switched on.

Thereafter the procedure below was followed:

1. The water bath, the sampling valve, the mixture in the

dilutor cell and all other tubing were allowed to equilibrate to their

respective set-point temperatures, the magnetic stirrer being switched on;

2. The inert gas was allowed to flow through the cell. A

bubble soap flow-meter was used to measure the flow rate. Li et al. (1993)

suggested that the infinite dilution activity coefficient obtained should be

independent of the flow rate;

3. The gas sampling valve was set to the fill? position,

allowing the inert gas to flow for some minutes;

4. The gas sampling valve was set to the inject? position for

one to two minutes;

5. The sampling valve was set back to the fill? position;

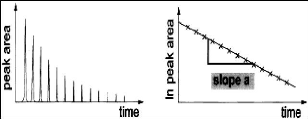

6. Steps 4 and 5 were repeated periodically. The time

interval between two successive injections depended on the system under

investigation. The natural logarithm of the solute peak area was expected to

decrease linearly with time as illustrated by figure 4-3 which was taken from a

publication by Krummen et al. (2000);

7. After a number of runs with sufficient data to compute

infinite dilution activity coefficient values, the experiment was ended.

Equation (3-90) was used to determine experimental IDAC values.

Figure 4-3: Typical plots of solute GC peak area

and ln (solute peak area) versus time.

|