Chapter 2 Experimental

2.1 Materials

Styrene was distilled under vacuum and stored in a freezer

until use. Maleimide 2,6-diaminopyridine were used commercially. AIBN

(2,2'-azobutironitrile) was recrystallised from methanol before use. DMSO was

purified and dried by standard techniques before use. CH3OH and

CH2Cl2 were used commercially.

2.2 Instruments

1H-NMR of copolymer samples were taken in

CDCl3 on a Bruker 600 MHz spectrophotometer with DMSO as a solvent.

The glass temperature transition was determined by differential scanning

calorimeter (DSC) and was performed on a Perkin Elmer Pyris 1 under nitrogen

with a scan rate of 10o C/min. The glass temperature transition Tg

is the midpoint in the heat-capacity change.

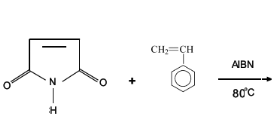

2.3 Synthesis of random copolymers of styrene and

maleimide

Copolymer of styrene and maleimide were prepared by a free

radical copolymerization using AIBN as the radical initiator and DMSO as

solvent. The synthesis of random copolymers of styrene and maleimide (Fig. 2-1)

which can serve as an example was performed as follow:

Styrene and Maleimide solution was prepared in DMSO. Styrene

solution was added with AIBN (80% w/w of the total monomer concentration) in a

3-necked round-bottomed flask equipped with a reflux condenser, mechanical

stirrer and nitrogen inlet (septum and a long needle). Maleimide solution was

added dropwise with AIBN (20% w/w of the total monomer concentration) shortly

and slowly. The polymer solution was precipitated in water and the resulting

polymer was dissolve in CH2Cl2 and precipitated in

CH3OH, then dried in vacuum at 60oC.

Fig 2-1 Synthesis Copolymerization of

Styrene and Maleimide

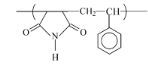

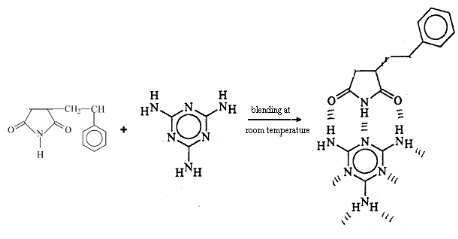

2.4 preparation of Blends of Styrene/Maleimide

copolymer and melamine or 2,6-diaminopyridine

Co-precipitation method was used to blend melamine or

2,6-diaminopyridine with imides containing copolymers. A

series of experiments was done to blend Styrene-Maleimide copolymers with

melamine or 2,6-diaminopyridine. Copolymers based on

styrene-maleimide were mixed homogenously with various amounts of melamine and

carefully dissolved in DMSO for 30 minutes, then co-precipitated in water. The

resulting polymer was dissolve in CH2Cl2 and precipitated

again in CH3OH then dried in vacuum at 50oC. After

filtration, washing and drying the yield of the blend was determined

[7].

Fig 2-2 blend of Styrene-Maleimide and

Melamine

Fig 2-3 Blend of Styrene-Maleimide and

2,6-diaminopyridine

|