Conclusion

103

Conclusion

Conclusion

In this study our main purpose is to have very thin coating

with high mechanical and thermal properties ( hardness and low friction

coefficient) in order to use it in the car industry to limit the energy losses

by friction between the piston and the cylinder , the used samples are taken

from a real piston to have more realistic results.

In the way of searching to upgrade the mechanical

characteristics of ordinary surfaces (the wear and the abrasive resistance ),

we chose to deposit a thin layer based on titanium and tungsten in a medium

containing 5% of nitrogen gas and the rest is argon gas, the choice in its se

is innovative because this coating is not a very well-known one in the

industrial field , the combination of titanium which is relatively a light

material with excellent corrosion resistance and in the other side the hardness

of the tungsten and its very high melting point provide the necessary

improvement for the engine pistons to reach a very high efficiency .

We noticed that The thin film layer grow mainly from a

nanoparticles with a diameter less than 1um, the interaction of this

nanoparticles with each other form a micro particles called clusters, the

growth of this clusters will form a columnar structure which will end by

creating a granular structure with an inter-granular space which is in direct

relation with the used energy and the deposition speed.

The measurement of the thin film thickness indicate that the

deposition speed have a value of 0.30nm/s which is a very high speed if we take

in consideration that the diameter of the atoms is a few Angstroms , so the

growth of the thin film layer is taking place by accumulation of macro

molecules with different orientation on the top of the surface which will cause

a none Crystallographic alignment to appear, so in order to have a uniform

structure we recommend to increase the energy of deposition in in order to

break the molecules bond to a small one which will increase significantly the

density and the porosity of the thin film enabling us to reach a higher

mechanical and thermal properties

The obtained structure present a low hardness of 2 Gpa with a

value of 0.9 for the friction coefficient which is very good if we take in

consideration that the deposited thin layer have an amorphous and heterogeneous

structure and low density.

Even if the result of the Ti-W-N thin layer deposited on a

sample of aluminum -silicon sample are not what we hoped for because they

didn't reach the hardness of the usual hard thin films, in the other side the

samples of stainless steel with the same deposition condition of temperature

and pressure gave much greater value than the aluminum samples

104

Conclusion

In order to a better characterization of the surface we

established a corrosion test for the samples with and without thin layer , the

results were significant , and they confirmed the previous results , the

corrosion rate for the coated area were much greater than the bare ones which

is mainly due to the high porosity of the surface

This study enable us to break into the nanomaterials world and

to discover the and to discover the large potential of this field and for our

study it's still promising in order to achieve the hardness of the ultra-hard

materials, and also the part that we didn't get into it which is the thermal

conductivity of the surface mainly because the lack of the necessary equipment

to measure the thermal conductivity which is a very important parameter to

determine if the coating represent a thermal barrier between the combustion

chamber and the aluminum piston, and if its right it will decrease the energy

losses through the piston enabling us to reach high thermal efficiency.

Appendices

AI 2

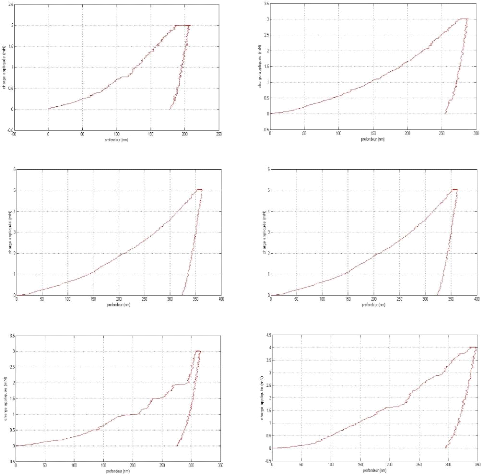

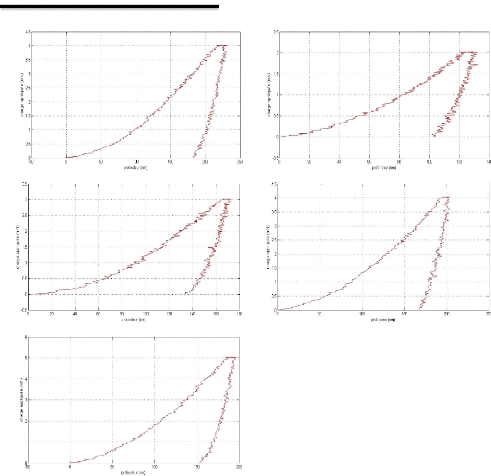

Appendix I: nanoindentation loading-unloading

curves

Appendix I: Nanoindentation loading-unloading

curves

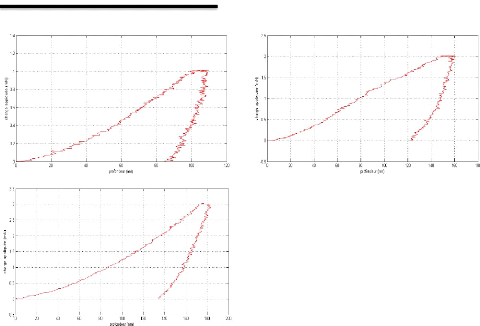

1. Aluminum-silicon without a layer

Appendix I: nanoindentation loading-unloading

curves

Fig.I.1: loading-unloading curves for 7 tests of

aluminum-silicon sample without a layer

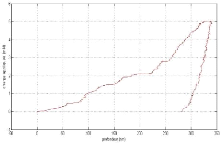

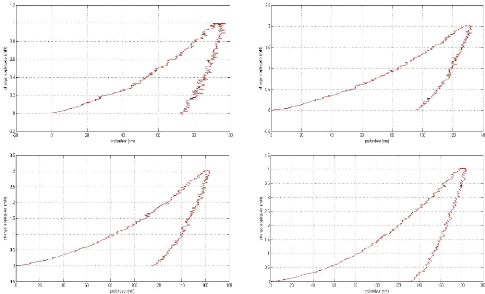

2. Aluminum-silicon with a Ti-W-N layer

AI 3

AI 4

Appendix I: nanoindentation loading-unloading

curves

Appendix I: nanoindentation loading-unloading

curves

AI 5

Fig.I.2: loading-unloading curves for 15 tests of

aluminum-silicon sample with a Ti-W-N layer

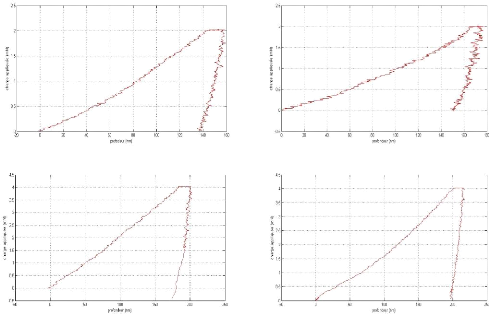

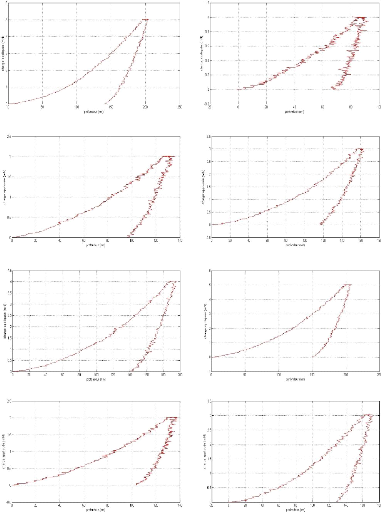

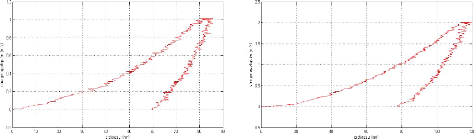

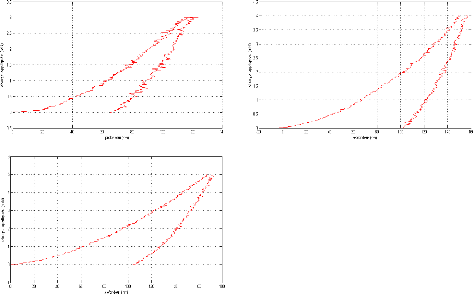

3. Stainless steel with a Ti-W-N layer

AI 6

Appendix I: nanoindentation loading-unloading

curves

AI 7

Appendix I: nanoindentation loading-unloading

curves

Appendix I: nanoindentation loading-unloading

curves

AI 8

Fig.I.3: loading-unloading curves for 25 tests of stainless

steel sample with a Ti-W-N layer

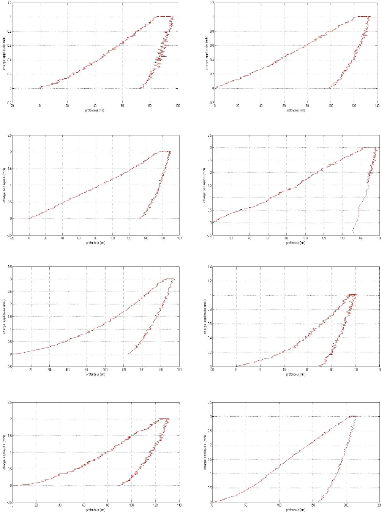

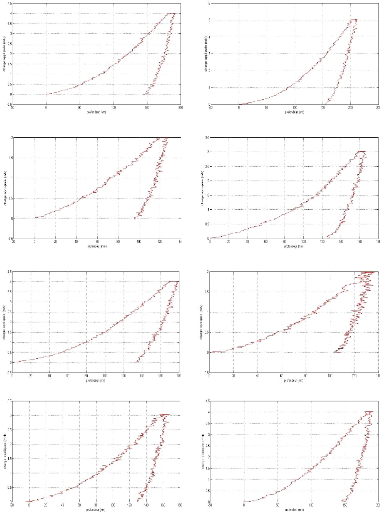

4. Stainless steel with double layers of Al-Si and

Ti-W-N

Appendix I: nanoindentation loading-unloading

curves

AI 9

Fig.I.4: loading-unloading curves for 05 tests of stainless

steel sample with double layers of Al-Si and Ti-W-N

AII 1

Appendix II: Nanoindentation results

Appendix II: Nanoindentation results

1. Aluminum-silicon without a layer

|

Tests

|

Modulus of elasticity E (GPa)

|

Hardness H (MPa)

|

Hardness HV

|

|

#01

|

95.921

|

2550.3

|

236.18

|

|

#02

|

100.03

|

2105.9

|

100.03

|

|

#03

|

115.81

|

2615.5

|

242.23

|

|

#04

|

101.34

|

2309.9

|

213.93

|

|

#05

|

86.902

|

1774.4

|

164.33

|

|

#06

|

69.493

|

2051.5

|

189.99

|

|

#07

|

101.67

|

2615.5

|

242.23

|

Table II.1 results of 7 tests of the aluminum-silicon

sample without layer

2. Aluminum-silicon with a Ti-W-N layer

|

Tests

|

Modulus of elasticity E (GPa)

|

Hardness H (MPa)

|

Hardness HV

|

|

#01

|

150.87

|

4214

|

390.26

|

|

#02

|

89.186

|

3795.2

|

351.48

|

|

#03

|

184.44

|

6037

|

559.09

|

|

#04

|

316.43

|

4546.2

|

421.03

|

|

#05

|

109.92

|

6358.7

|

588.89

|

|

#06

|

142.71

|

6218.1

|

575.86

|

|

#07

|

109.32

|

3810.1

|

352.86

|

|

#08

|

153.16

|

5774.6

|

534.79

|

|

#09

|

112.85

|

5957.7

|

551.75

|

|

#10

|

103.58

|

6354.5

|

588.49

|

|

#11

|

117.62

|

7143

|

661.52

|

|

#12

|

79.703

|

4012.2

|

371.57

|

|

#13

|

121.8

|

4289.5

|

397.25

|

AII 2

Appendix II: Nanoindentation results

|

#14

|

127.34

|

4149

|

384.24

|

|

#15

|

106.49

|

5476.3

|

507.17

|

Table II.2 results of 15 tests on the aluminum-silicon bar

with a Ti-W-N layer

3. Stainless steel with a Ti-W-N layer

|

Tests

|

Modulus of elasticity E (GPa)

|

Hardness H (MPa)

|

Hardness HV

|

|

#01

|

125.53

|

6187.7

|

573.05

|

|

#02

|

131.93

|

6494

|

601.41

|

|

#03

|

118.86

|

6714.9

|

621.87

|

|

#04

|

142.77

|

7271.3

|

673.4

|

|

#05

|

138.92

|

7634.4

|

707.03

|

|

#06

|

122.4

|

7072

|

654.95

|

|

#07

|

113.57

|

6949.6

|

643.61

|

|

#08

|

128.51

|

6735.1

|

623.74

|

|

#09

|

134.99

|

6289.6

|

582.49

|

|

#10

|

162.25

|

7032

|

651.24

|

|

#11

|

145.59

|

5856.7

|

542.4

|

|

#12

|

128.83

|

6301.8

|

583.61

|

|

#13

|

176.64

|

6328.8

|

586.12

|

|

#14

|

148.6

|

6880.3

|

637.19

|

|

#15

|

158.82

|

7079.3

|

655.62

|

|

#16

|

160.43

|

6146.1

|

569.19

|

|

#17

|

175.3

|

7308.6

|

676.85

|

|

#18

|

115.72

|

6513.4

|

603.21

|

|

#19

|

149.03

|

6701.1

|

620.6

|

|

#20

|

145.26

|

6627.9

|

613.81

|

|

#21

|

147.96

|

5767.6

|

534.15

|

|

#22

|

155.61

|

6252.9

|

579.09

|

|

#23

|

159.42

|

5783.1

|

535.58

|

AII 3

Appendix II: Nanoindentation results

|

#24

|

148.23

|

5736.4

|

531.26

|

|

#25

|

239.02

|

7450

|

689.96

|

Table.II.3 results of 25 tests on the stainless steel bar

with a Ti-W-N layer

4. Stainless steel with double layers of Al-Si and

Ti-W-N

|

Tests

|

Modulus of elasticity E (GPa)

|

Hardness H (MPa)

|

Hardness HV

|

|

#01

|

151.25

|

8561.6

|

792.9

|

|

#02

|

143.94

|

8780.6

|

813.18

|

|

#03

|

164.64

|

17172

|

1590.3

|

|

#04

|

161.26

|

10408

|

963.9

|

|

#05

|

149.71

|

11397

|

1055.5

|

Table.5.4 results of 05 tests on the stainless steel bar

with double layers of Al-Si and Ti-W-N

|